Uma i- PCB inomhlabathi owengeziwe, kukhona i-SGND, AGND, GND, njll., kuye ngokuthi indawo ye- PCB ikuphi, "umhlabathi" oyinhloko usetshenziswa njengereferensi ye-copper coating ezimele, okungukuthi, umhlabathi uxhunywe ndawonye. .

Izakhiwo Zokugoqa Zethusi

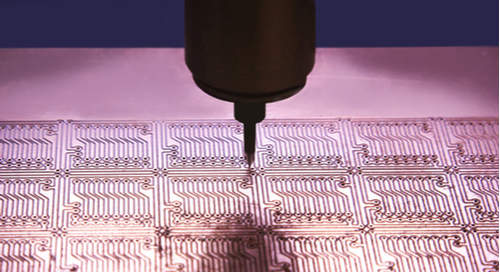

Izakhiwo ezigcwaliswe ngephedi zidinga ukuthi ngezimbobo kugqitshwe ithusi ukuze kuhanjiswe amasiginali phakathi kwezendlalelo ku-PCB yezendlalelo eziningi. Le plating ixhuma kwamanye amaphedi ezakhiweni ze-via-in-pad, kanye nakumkhondo oqondile kusetshenziswa indandatho encane ye-annular. Lezi zakhiwo zibalulekile, kodwa zaziwa ngokuba nezinkinga ezithile zokwethembeka ngaphansi kokuhamba ngebhayisikili okushisayo okuphindaphindiwe.

Amazinga e-IPC 6012E asanda kwengeza imfuneko yokugoqa ngethusi ezakhiweni ezingaphakathi kwephedi. I- copper platingkufanele iqhubeke izungeze unqenqema lwembobo futhi inabele eringini ye-annular ezungeze iphedi. Le mfuneko ithuthukisa ukwethembeka kwe- via plating futhi inamandla okunciphisa ukwehluleka ngenxa yokuqhekeka, noma ngenxa yokuhlukana phakathi kwezici ezingaphezulu kanye nokucwetshwa ngembobo.

Izakhiwo zokugoqa zethusi ezigcwele zivela ezinhlobonhlobo ezimbili. Okokuqala, ifilimu yethusi eqhubekayo ingasetshenziswa ngaphakathi kwe-via, ebese isonga phezu kwezingqimba ezingaphezulu nezingaphansi ekugcineni kwe-via. Le plating yokugoqa yethusi bese yenza i-via pad kanye nomkhondo oholela ku-via, kwakheka ukwakheka kwethusi okuqhubekayo.

Kungenjalo, i-via ingaba nephedi yayo ehlukile eyakhiwe emaphethelweni e-via. Lesi sendlalelo sephedi esihlukene sixhuma kulandelela noma ezindizeni eziphansi. I-copper plating egcwalisa i-via bese igoqa ngaphezulu kwale padi yangaphandle, yakhe inhlanganisela yezinqe phakathi kwe-copper fill plating kanye ne-via pad. Okunye ukubopha kwenzeka phakathi kwe-filling plating kanye ne-via pad, kodwa kokubili akuhlangani ndawonye futhi akwakhi isakhiwo esisodwa esiqhubekayo.

Kunezizathu eziningana zokufaka i-copper:

1. EMC. Indawo enkulu yomhlabathi noma ithusi yamandla, izovikela, nokunye okukhethekile, okufana ne-PGND ukuvikela.

2. Izidingo zenqubo ye-PCB. Ngokuvamile, ukuze kuqinisekiswe umphumela wokucwenga, noma i-laminate ayikhubazeki, ithusi lendlalelwa isendlalelo se-PCB ngezintambo ezincane.

3. Izidingo zobuqotho besignali, zinikeza isignali yedijithali yemvamisa ephezulu indlela ephelele yokubuya, futhi yehlise izintambo zenethiwekhi ye-DC. Yiqiniso, kukhona ukuchithwa kokushisa, ukufakwa kwedivayisi ekhethekile kudinga i-copper plating nokunye.

Inzuzo enkulu ye-copper plating ukunciphisa i-impedance yomugqa ophansi (okuthiwa ukuphikisana nokuphazanyiswa nakho kubangelwa ingxenye enkulu yokunciphisa i-impedance yomugqa ophansi). Kukhona ama-spike currents amaningi kusekethe yedijithali, ngakho-ke kudingekile kakhulu ukwehlisa i-impedance yomugqa waphansi. Ngokuvamile kunenkolelo yokuthi amasekhethi ahlanganiswe ngokuphelele ngamadivayisi edijithali kufanele abekwe phezu kwendawo enkulu, futhi kumasekhethi e-analog, iluphu yaphansi eyakhiwe ukufakwa kwethusi ingabangela ukuphazamiseka kokuhlangana kogesi ukuthi kube ngaphansi (ngaphandle kwamasekhethi aphezulu). Ngakho-ke, akuyona isifunda okufanele sibe yithusi (BTW: i-mesh yethusi ingcono kune-block yonke).

Ukubaluleka kwe-circuit copper plating:

1. Intambo yethusi nephansi ixhunyiwe, lokhu kunganciphisa indawo ye-loop

2. indawo enkulu ye-copper plating ilingana nokunciphisa ukumelana kocingo oluphansi, ukunciphisa ukwehla kokucindezela kusuka kulawa maphuzu amabili Kuthiwa kokubili umhlabathi wedijithali kanye nomhlabathi we-analog kufanele ube yithusi ukuze kwandiswe ikhono lokulwa nokuphazamiseka, futhi at ama-frequency aphezulu, umhlabathi wedijithali kanye nomhlabathi we-analog kufanele uhlukaniswe ukubeka ithusi, bese uxhunywe ngephuzu elilodwa, iphuzu elilodwa lingasebenzisa ucingo ukwenza ukuphenduka okumbalwa kwendandatho kazibuthe bese uxhuma. Kodwa-ke, uma imvamisa ingephezulu kakhulu, noma izimo zokusebenza zensimbi zingezimbi, ungakhululeka kancane. I-crystal ingabalwa njengomthombo we-high-frequency kumjikelezo. Ungabeka ithusi nxazonke bese ugaya i-crystal case, okungcono.

Uma ungathanda ukufunda okwengeziwe nge-YMS PCB, xhumana nathi nganoma yisiphi isikhathi.

Funda kabanzi ngemikhiqizo ye-YMS

Isikhathi sokuthumela: Apr-08-2022