I-Multilayer Pcb Manufacturer engcono kakhulu, imboni e-China

I-YMSPCB isetshenziselwa ukwenza nokuhlanganisa i-PCBS yezendlalelo eziningi ngamanani avumayo

I-Multilayer PCB Manufacturer

Njengoba ubuchwepheshe buqhubeka nokuthuthuka futhi nenani lama-PCBS asetshenziswayo kulindeleke ukuthi landa, inkampani yakho idinga ukutshala imali kulawa mathrendi futhi yandise ukugxila kwakho kuzixazululo zezendlalelo eziningi. Lokhu kugxilwa okungeziwe kufanele kufake phakathi ukusebenza nabakhiqizi be-PCB ye-multilayer kanye nabahlanganisi. Ngesixazululo esinjengalesi, inkampani yakho izolungela ngokugcwele ukuphatha noma iyiphi iphrojekthi ye-PCB enezingqimba eziningi ohlangabezana nayo. I-YMSPCB ingakusiza ukufeza izinhloso zakho.

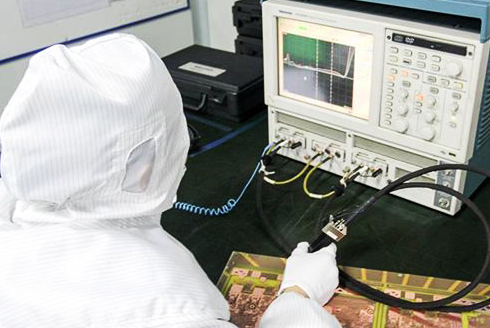

I- YMSPCB ingumhlinzeki wesixazululo we-PCB wangokwezifiso ohlinzeka ngezinsizakalo zokukhiqiza nezokuhlanganisa ze-PCB ezinkampanini emhlabeni jikelele. Sisiza izinkampani kusukela ekuthengeni izingxenye kuye ekuhlolweni kuyilapho sihlangabezana njalo ne-IPC Class 3, RoHS kanye namazinga e-ISO9001:2008. Sizoba nawe kuzo zonke izinyathelo kuyo yonke inqubo yokukhiqiza i-PCBS enezingqimba eziningi futhi sinikeze ubuchwepheshe nezeluleko lapho kudingeka. Ithimba lethu elinolwazi likhiqize izinkulungwane zama- PCBS anezingqimba eziningi ezihluka ngomklamo nobunkimbinkimbi. Kungakhathaliseki ukuthi idizayini iyinkimbinkimbi kangakanani noma ukuthi ziningi kangakanani izidingo zakho, i-YMSPCB ingasiza.

Ukuze ufunde kabanzi mayelana ne-YMSPCB namandla ethu okukhiqiza nokuhlanganisa, hlola amakhono ethu okukhiqiza nokuhlanganisa ngokuchofoza izixhumanisi zekhasi elilandelayo. Uma ungathanda ulwazi olwengeziwe ngokuthi singakusiza kanjani ngabanye, sicela ukhululeke ukuxhumana nathi ngokuqondile ngombuzo.

Best Multilayer Pcb Manufacturer

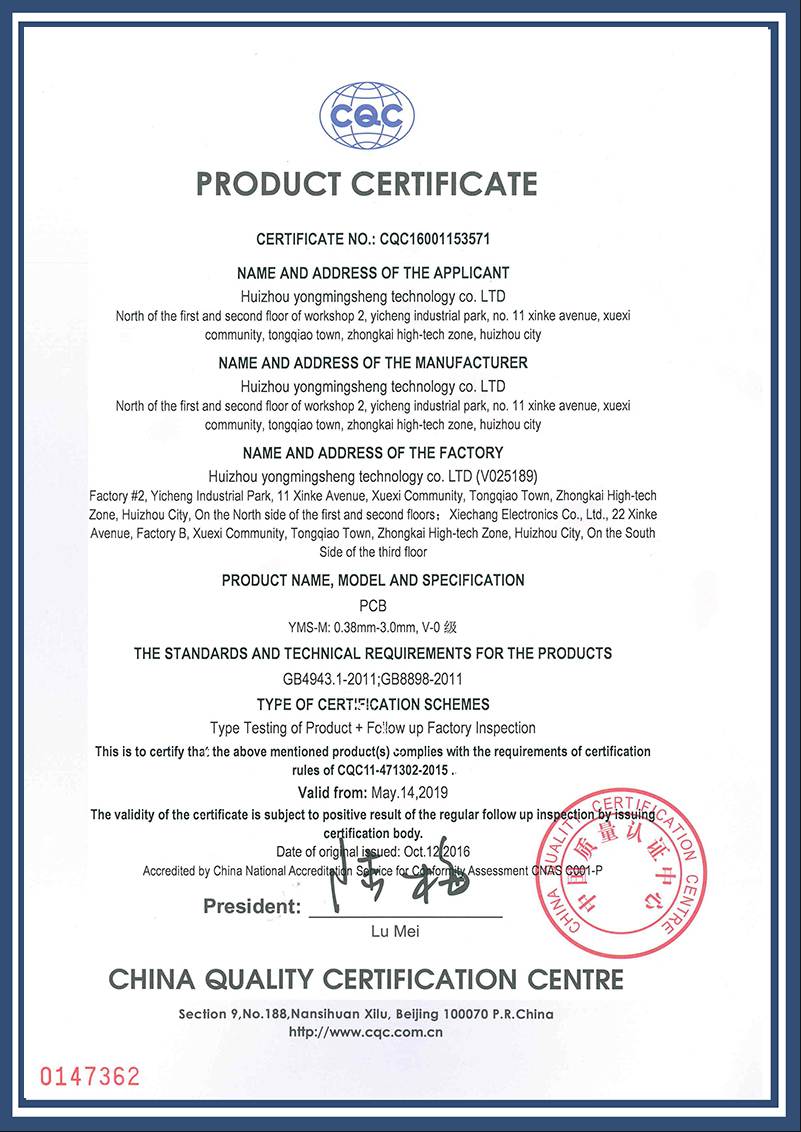

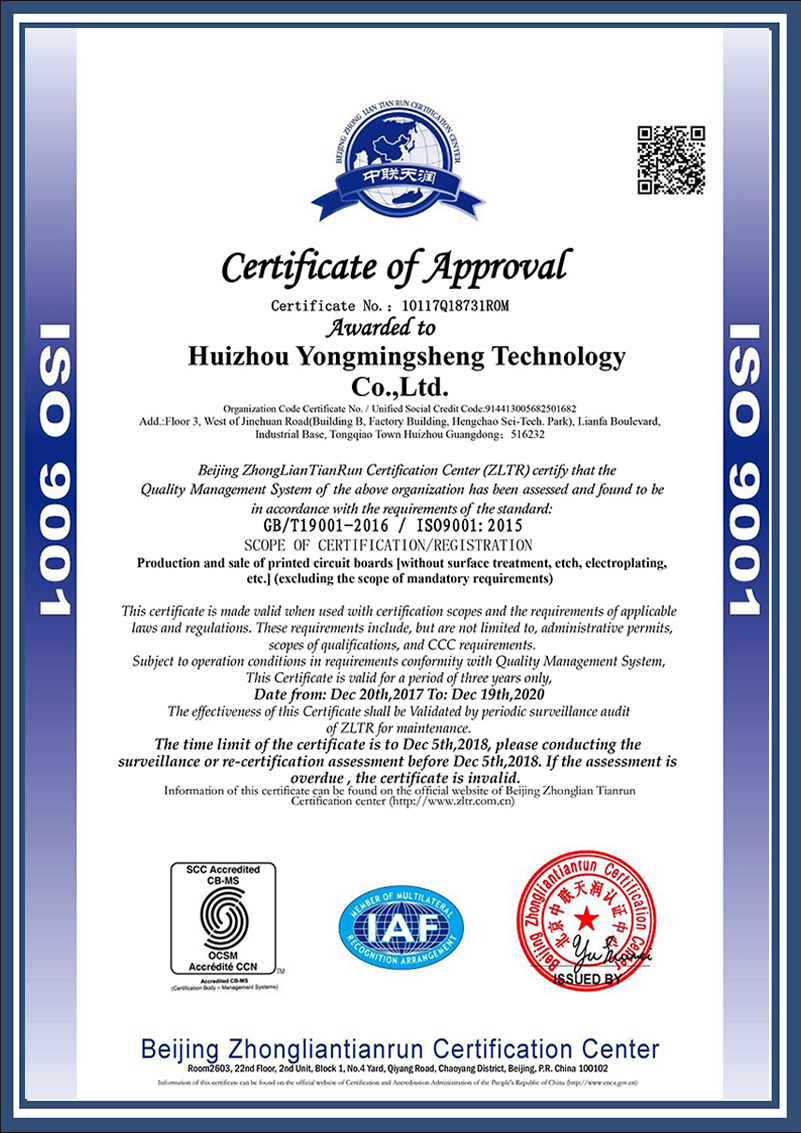

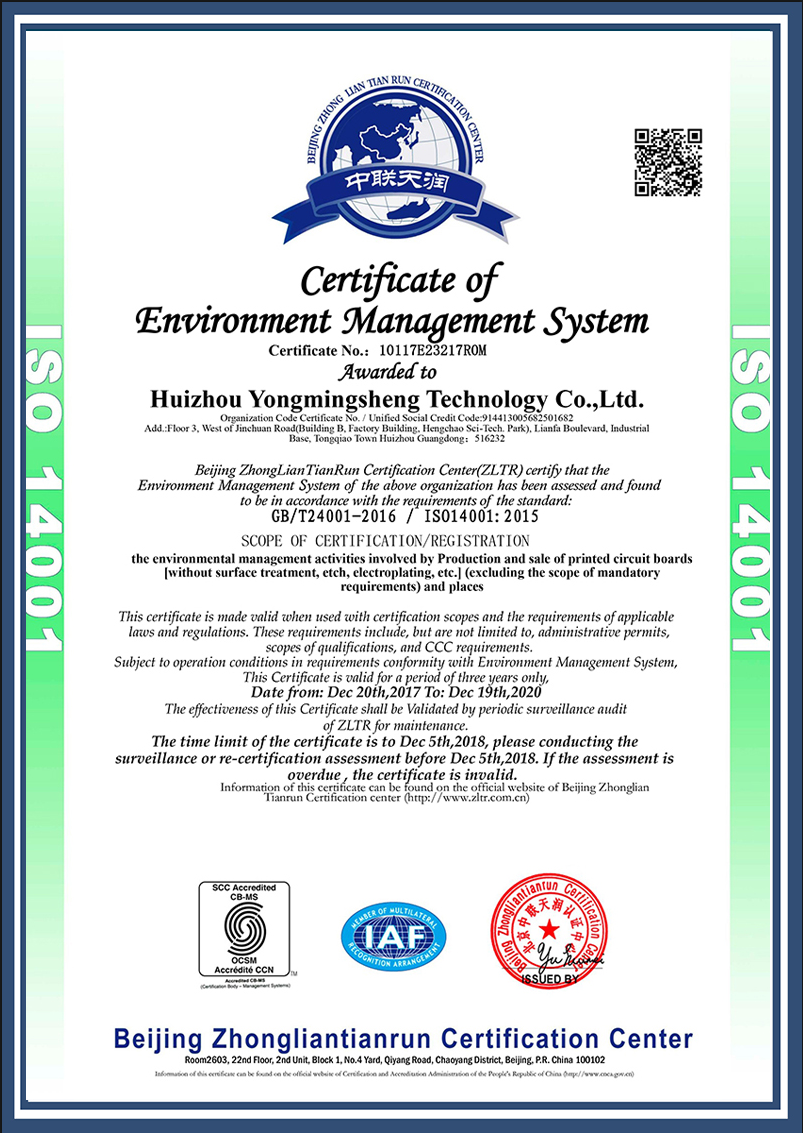

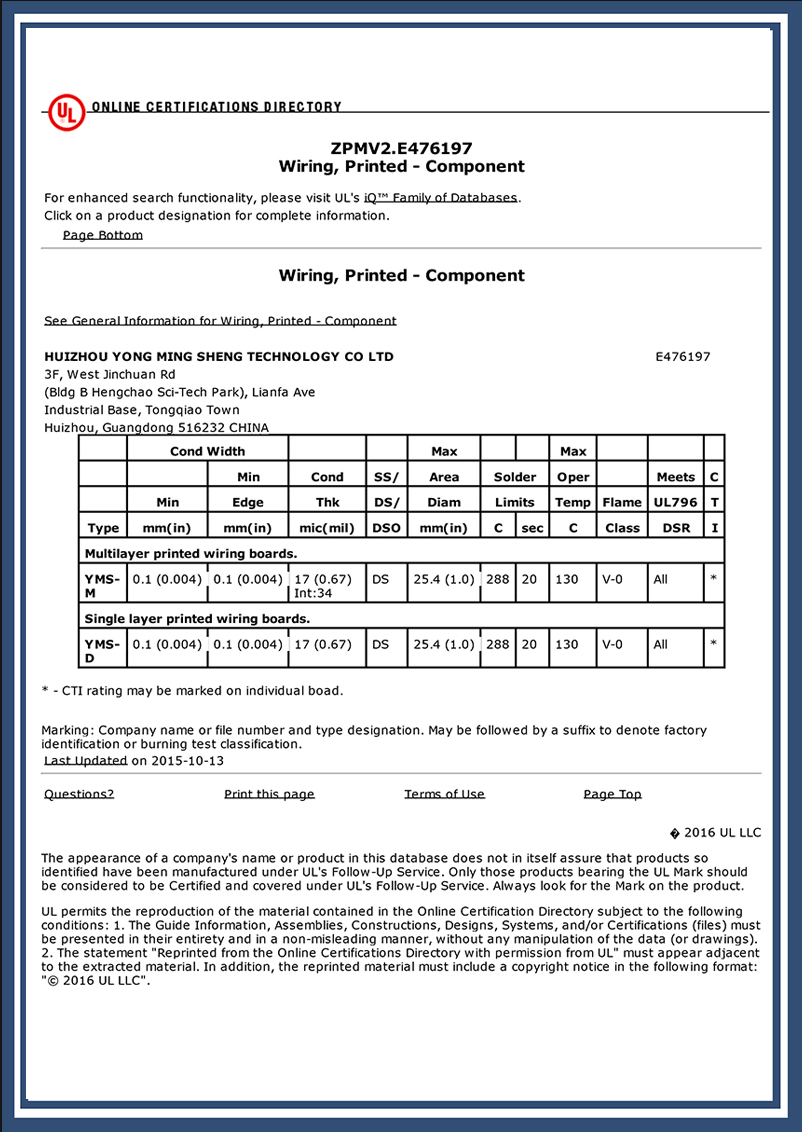

Izitifiketi Ezivela Ku-PCB Manufacturer Nefekthri

I izitifiketi kanye neticu esizuzwe ngamanga YMS wokugcina angu-10 eminyakeni engu-zimi kanje:

isitifiketi ISO9001 (Ngo-2015),

isitifiketi UL (Ngo-2015),

CQC isitifiketi Cha 16001153571

Advanced ibhizinisi ubuchwepheshe (Ngo-2018),

Ubuchwepheshe obusha futhi okusezingeni eliphezulu ibhizinisi (Ngo-2018),

isitifiketi ISO14001 (ngo-2015),

IATF16949 izinga uhlelo (e 2019).

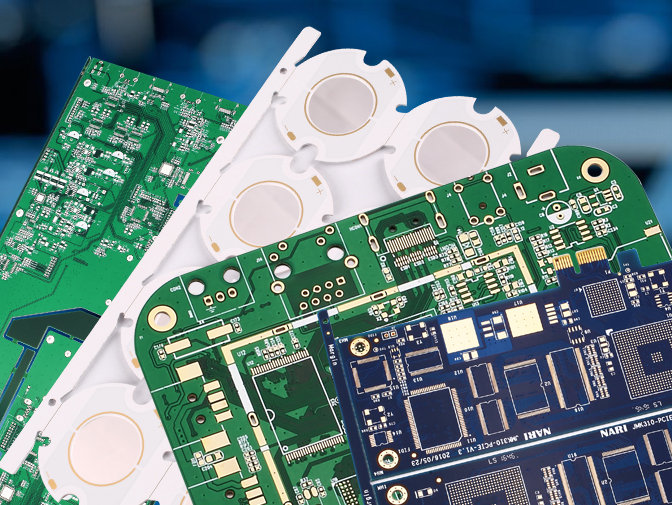

Khetha ama-PCB wakho Wezithako eziningi

I-Multilayer PCB iyibhodi lesifunda eliphrintiwe elinezendlalelo ezingaphezu kwezingu-2, Ngokungafani ne-Double-Sided PCB enezingxenye ezimbili kuphela ze-conductive, wonke ama-PCB amaningi kufanele abe okungenani izendlalelo ezintathu zezinto eziqhutshwayo ezingcwatshwe phakathi nendawo. impahla.

I-YMSPCB ibikhiqiza ama-PCB amaningi ngaphezu kweminyaka eyi-10. Eminyakeni edlule, sibone zonke izinhlobo zezakhiwo ze-multilayer ezivela ezimbonini ezihlukahlukene, saphendula zonke izinhlobo zemibuzo ye-multilayer, futhi saxazulula zonke izinhlobo zezinkinga ngama-PCB amaningi.

Kungani Khetha i-YMCPCB

Njengomkhiqizi we-PCB we-multilayer ochwepheshe kanye nefekthri, indawo yethu iwukuba ubuchwepheshe bekhasimende, ukukhiqiza, ukuthengisa emva kokuthengisa, ithimba le-R&D, ngokushesha futhi ngobungcweti ukuhlinzeka ngezixazululo zokukhiqiza ze-multilayer pcb ukuxazulula izinkinga ezahlukahlukene amakhasimende ahlangabezana nazo. Amakhasimende ethu adinga kuphela ukwenza umsebenzi omuhle ekuthengisweni kwama-PC amaningi, ezinye izinto ezifana nezindleko zokulawula, ukwakheka kwe-PCB nezisombululo, kanye nangemuva kokuthengisa, sizosiza amakhasimende ukubhekana nakho ukuze kwandiswe izinzuzo zekhasimende.

Izinyathelo Ezisetshenziswa Ekwenziweni Kwe-Multilayer PCB

Hlela idizayini ye-PCB yesakhiwo ngokulandela zonke izimfuneko bese uyibhala ngekhodi. Ngokwenza lokhu, uqinisekisa ukuthi izici ezihlukene nezingxenye zemiklamo azinawo amaphutha. Umklamo oqediwe we-PCB usulungele ukwakha.

Ngokushesha nje lapho ukuqedwa kokuhlolwa sekuqediwe kumklamo, kunganyatheliswa. Ubhoboza imbobo yokubhalisa ukuze usebenze njengomhlahlandlela wokuqondanisa amafilimu njengoba uqhubeka nenqubo.

Lesi sinyathelo ngesokuqala ngenkathi senza ungqimba lwangaphakathi lwe-PCB. Uphrinta umklamo we-PCB we-multilayer; khona-ke ithusi liphinde lihlanganiswe nocezu lwe-lamine olusebenza njengesakhiwo se-PCB.

Ithusi elingasimbozi i-photoresist likhishwa ngamakhemikhali anamandla futhi asebenzayo. Lapho nje isusiwe, ishiya ithusi elidingekayo le-PCB yakho.

Uma izendlalelo sezingenasici, ungakwazi ukuzihlanganisa. Ungakwazi ukufeza le nqubo ngama-spes amabili, ahlanganisa ukubeka-up kanye nesinyathelo se-laminating.

Ngaphambi kokubhoboza, indawo yokubhoboza itholakala ngomshini we-x-ray. Lokhu kusiza ekuvikeleni isitaki se-PCB.

Le nqubo isiza ekuhlanganiseni izendlalelo ze-PCB ezihlukene zisebenzisa ikhemikhali.

Ngokwenza lokhu uqapha ithusi elitholakala kungqimba lwangaphandle ngokusebenzisa i-photoresist.

Ukuze kuvikelwe ithusi ngesikhathi senqubo, kusetshenziswa i-tin guard. Lokhu kuqeda ithusi elingafunwa. Lokhu futhi kuqinisekisa ukuxhumana okusungulwe kahle kwe-PCB.

Ngemva kokuhlanza amaphaneli e-PCB, usebenzisa i-epoxy ye-inki enemaski ye-solder.

Ukufakwa kwe-PCB kwenziwa ukuze kuqinisekiswe ukuthi ukuhlanganisa izingxenye kungafinyelelwa. Inqubo yokuhlola ikhomba lonke ulwazi olubalulekile ku-PCB.

Ukuqinisekisa ukusebenza, uchwepheshe wenza izivivinyo ezindaweni ezimbalwa ze-PCB.

Ngokwezidingo zekhasimende, ama-PCB ahlukene ayasikwa kuphaneli yokuqala. Khona-ke ukuhlolwa kwebhodi kwenziwa, futhi amaphutha alungiswa ngaphambi kokuba athunyelwe ukulethwa.

Izinqubo Zokukhiqiza Ama-PCB Wezingqimba Eziningi

Ngenxa yesidingo esikhulu sama-PCB anezingqimba eziningi ukuze asetshenziswe kumishini yobuchwepheshe, izinto zokunakekelwa kwempilo, ukusetshenziswa kwezempi, ngisho nemikhiqizo enjalo yabathengi njengamathelevishini ahlakaniphile nemishini yokuqapha ekhaya, abakhiqizi abaningi abaqhudelanayo bazibeke endaweni yabo ukuze baphendule esidingweni sala mabhodi. Kusele ingxubevange yamakhono phakathi kwabaqambi abahlobene namandla okukhiqiza ivolumu, kanye nenani lezendlalelo ze-PCB ezingakhiqizwa.

Ukukhiqizwa kwama-PCB anezingqimba eziningi kuhilela inqubo yokuhlanganisa izingqimba ezishintshayo ze-prepreg kanye nezinto eziwumgogodla zibe yiyunithi eyodwa, kusetshenziswa ukushisa nokucindezela okuphezulu ukuze kuqinisekiswe ukugqunywa okufanayo kwamakhondatha, ukuqedwa komoya phakathi kwezingqimba, kanye nokuphulukiswa okufanele kwezinamathiselo ezihlanganisa izingqimba ndawonye.

Ngenxa yezingqimba eziningi zezinto, ukukhishwa kwezimbobo zokubhoboza phakathi kwezendlalelo kufanele kubhekwe ngokucophelela futhi kubhaliswe. Kubalulekile ekwenziweni ngempumelelo kwama-PCB anezingqimba eziningi ukuthi onjiniyela bafake ukwakheka kwe-symmetrical kuzo zonke izendlalelo, ukusiza ukugwema ukusonteka noma ukukhothama ezintweni lapho kufakwa ukushisa nokucindezela.

Lapho uthungatha umenzi wama-PCB anezingqimba eziningi, kubaluleke kakhulu ukuthola amakhono omkhiqizi nokubekezelela okujwayelekile kwalawa mabhodi ayinkimbinkimbi, futhi kusetshenziswe amasu edizayini yokukhiqiza (DFM) ukuze kuhlangatshezwane nalawo mazinga. Lokhu kuhamba ibanga elide ekwakheni ukuzethemba kokuthi umphumela uzohlangabezana nakho konke okulindelwe ukusebenza, ukwethembeka, nokusebenza.

Izinzuzo Nokubi

Izinzuzo zama-PCB amaningi

1. Usayizi omncane: Inzuzo evelele kakhulu futhi ehlonishwayo ye-PCBS yezingxenye eziningi ubukhulu bayo. Ngenxa yokwakheka kwayo okunezingqimba, i-PCBS enezingqimba eziningi mancane kakhulu ngevolumu kunamanye ama-PCBS anomsebenzi ofanayo. Lokhu kuye kwaholela ezinzuzweni eziphawulekayo zama-electronics wesimanje, ukuzivumelanisa nethrendi yamanje eya ezintweni ezincane, ezihlangene kodwa ezinamandla kakhulu, njengama-smartphone, amakhompyutha aphathekayo, amaphilisi kanye nezinto ezigqokwayo.

2. Ukwakhiwa kwe-lightweight: I-PCB encane, isisindo esincane, esizuzisa umklamo, ikakhulukazi uma izixhumi eziningi ezihlukene ezidingekayo ze-PCBS eyodwa kanye ne-double layer ziqedwa. Futhi elungele ukwakhiwa komkhiqizo wesimanje we-elekthronikhi, vele uzivumelanise nokuchema kwazo kokuhamba.

3. Ikhwalithi Ephezulu: Ngenxa yenani lomsebenzi nokuhlela okumele kungene ekudaleni i-PCBS yezendlalelo eziningi, lezi zinhlobo ze-PCBS zivame ukwedlula i-PCBS yesendlalelo esisodwa nekabili ngekhwalithi. Ngenxa yalokho, nabo bavame ukwethembeka kakhulu.

4. Ukuqina: Izinto ze-Multilayer PCB zivame ukuqina ngoba akumele zithwale isisindo sazo kuphela, kodwa futhi zikwazi ukumelana nokushisa nokucindezela okusetshenziselwa ukuzihlanganisa ndawonye. Ngaphezu kwalokho, ama-PCB anezingqimba eziningi anezingqimba eziningi zokufaka phakathi kwezingqimba zesekethe futhi asebenzisa izinto zokunamathisela ezandulelayo nezinto ezivikelayo, ezizenza ziqine kakhudlwana.

5. Ukuvumelana nezimo: Nakuba lokhu kungasebenzi kuzo zonke izingxenye ze-PCB yezendlalelo eziningi, ezinye zisebenzisa amasu okwakha aguquguqukayo, okuphumela ku-PCBS yezendlalelo eziningi eziguquguqukayo. Lokhu kungase kube isici esifiselekayo ezinhlelweni zokusebenza lapho ukugoba nokugoba kancane kungase kwenzeke njalo nje.

6. Indawo yokuxhumana eyodwa: I-Multilayer PCBS yakhelwe ukusebenza njengeyunithi eyodwa esikhundleni sochungechunge nezinye izingxenye ze-PCB. Njengomphumela, banephuzu elilodwa kuphela lokuxhumana, kunezindawo eziningi zokuxhuma ezidingekayo ukuze kusetshenziswe i-PCBS eminingi yongqimba olulodwa. Kuvela ukuthi lokhu kuyazuzisa futhi kumiklamo ye-elekthronikhi, njengoba idinga kuphela ukufaka indawo eyodwa yokuxhuma emkhiqizweni wokugcina. Lokhu kunenzuzo ikakhulukazi kuma-electronics amancane namagajethi aklanyelwe ukunciphisa usayizi nesisindo.

Ukungalungi kwama-PCB amaningi

1. Izindleko eziphakeme: I-Multilayer PCBS ibiza kakhulu kune-PCBS yongqimba olulodwa nekabili kuzo zonke izigaba zenqubo yokukhiqiza. Isigaba sokuklama, esithatha isikhathi esiningi ukuxazulula noma yiziphi izinkinga ezingase zibe khona. Isiteji sokukhiqiza sidinga imishini ebiza kakhulu kanye nezinqubo zokukhiqiza eziyinkimbinkimbi kakhulu, ezidla isikhathi esiningi nomsebenzi wabahlanganisi. Ukwengeza, noma yimaphi amaphutha enqubweni yokukhiqiza noma yokuhlanganisa anzima ukusetshenzwa kabusha, futhi ukukhipha kunezela izindleko ezengeziwe zabasebenzi noma izindleko ezilahliwe.

2. Ukutholakala okulinganiselwe: Imishini yokukhiqiza ye-PCB enezingqimba eziningi ayitholakali kubo bonke abakhiqizi be-PCB ngenxa yokuthi banemali noma banesidingo. Lokhu kukhawulela inani labakhiqizi be-PCB abangakhiqiza i-PCBS yezendlalelo eziningi kumakhasimende.

3. Udinga umklami onekhono: Njengoba kushiwo ngaphambili, i-PCBS enezingqimba eziningi idinga ukwakheka okuningi kwangaphambilini. Lokhu kungaba yinkinga ngaphandle kokuhlangenwe nakho kwangaphambilini. Amabhodi we-multilayer adinga ukuxhumana kwe-interlayer, kodwa izinkinga ze-crosstalk kanye ne-impedance kufanele zincishiswe ngesikhathi esifanayo. Inkinga ekuklanyweni ingase ibangele ukuthi ibhodi lingasebenzi kahle.

4. Isikhathi sokukhiqiza: ngokwanda kobunzima, izidingo zokukhiqiza nazo ziyakhula, okuzoholela esilinganisweni senzuzo ye-PCB enezingqimba eziningi. Ibhodi lesifunda ngalinye lithatha isikhathi esiningi ukukhiqiza, okuholela ezindlekweni ezengeziwe zokusebenza. Ngakho isikhathi phakathi kokufaka i-oda nokwamukela umkhiqizo side, okungaba inkinga kwezinye izimo.

I-Multilayer PCB Isicelo

Izinzuzo nokuqhathanisa okuxoxwe ngakho ngenhla kuholela embuzweni: Iyini ukusetshenziswa kwe-PCBS yezingxenye eziningi emhlabeni wangempela? Impendulo cishe yonke into.

Ezimbonini eziningi, i-PCB ye-multilayer isibe yisinqumo sokuqala sezinhlelo zokusebenza ezihlukahlukene. Okuningi kwalokhu okuthandwayo kuvela ekuphusheni okuqhubekayo kokuhamba nokusebenza kubo bonke ubuchwepheshe. I-Multilayer PCBS isinyathelo esiphusile kule nqubo, esivumela ukusebenza okukhulu ngenkathi kunciphisa usayizi. Ngenxa yalokho, sezivamile futhi zisetshenziswa kubuchwepheshe obuningi, kufaka phakathi:

1. I-Consumer electronics: I-Consumer electronics igama elibanzi elisetshenziselwa ukuhlanganisa imikhiqizo eminingi esetshenziswa umphakathi jikelele. Lokhu kuvame ukufaka imikhiqizo esetshenziswa nsuku zonke, njengama-smartphone nama-microwave. Le mikhiqizo kagesi yabathengi iya ngokuya isebenzisa i-PCBS enezingqimba eziningi. Kungani kunjalo? Iningi lempendulo ilele kuzitayela zabathengi. Abantu emhlabeni wanamuhla bavame ukukhetha amagajethi anemisebenzi eminingi namadivayisi ahlakaniphile ahlanganiswe ezimpilweni zabo. Kusukela kuzilawuli kude zomhlaba wonke ukuya kuma-smartwatches, lezi zinhlobo zamadivayisi zivame kakhulu emhlabeni wanamuhla. Futhi bavame ukusebenzisa i-PCBS enezingqimba eziningi ukukhulisa ukusebenza nokunciphisa usayizi.

2. Izinto zikagesi zamakhompiyutha: I-Multilayer PCBS isetshenziselwa yonke into kusukela kumaseva ukuya kumabhodi omama, ikakhulukazi ngenxa yezakhiwo zawo zokonga isikhala nokusebenza okuphezulu. Kulezi zinhlelo zokusebenza, ukusebenza kungenye yezimpawu ezibaluleke kakhulu ze-PCB, kuyilapho izindleko ziphansi kakhulu ohlwini lwezinto ezibalulekile. Ngakho-ke, i-PCBS ye-multilayer iyisisombululo esihle sobuchwepheshe obuningi embonini.

3. Ezokuxhumana: Imishini yokuxhumana ngocingo ivamise ukusebenzisa i-PCBS enezingqimba eziningi ezinhlelweni eziningi ezijwayelekile, njengokudluliswa kwesignali, i-GPS, nezinhlelo zokusebenza zesathelayithi. Izizathu zibangelwa ikakhulukazi ukuqina nokusebenza kwazo. I-PCBS yezinhlelo zokusebenza zokuxhumana ngocingo ngokuvamile isetshenziswa kumadivayisi eselula noma imibhoshongo yangaphandle. Kulezi zinhlelo zokusebenza, ukuqina kubalulekile ngenkathi kugcinwa izinga eliphezulu lokusebenza.

4. Imboni: Ama-PCBS amaningi abonakala ehlala isikhathi eside kunezinye izinketho ezimbalwa ezimakethe njengamanje, okuwenza alungele ukusetshenziswa kwansuku zonke lapho ukuphathwa kabi kungase kwenzeke. Ngenxa yalokho, i-PCBS ye-multilayer isiye yaduma ezinhlelweni ezihlukahlukene zezimboni, okuphawuleka kakhulu ukulawulwa kwezimboni. Kusukela kumakhompiyutha ezimboni kuya kumasistimu okulawula, i-PCBS enezingqimba eziningi isetshenziswa kuzo zonke izinhlelo zokusebenza zokukhiqiza nezimboni ukusebenzisa imishini futhi ithandwa ngenxa yokuqina kwayo kanye nobuncane bayo kanye nokusebenza kwayo.

5. Imishini yezokwelapha: Ezogesi ziba ingxenye ebaluleke kakhulu embonini yezokunakekelwa kwempilo, zidlala indima kukho konke kusukela ekwelashweni kuye ekuxilongweni. I-Multilayer PCBS ithandwa kakhulu imboni yezokwelapha ngenxa yobukhulu bayo obuncane, isisindo esilula, kanye nokusebenza okumangazayo uma kuqhathaniswa nezinye izindlela zongqimba olulodwa. Lezi zinzuzo ziholele ekutheni i-PCBS ye-multilayer isetshenziswe emishinini yesimanje ye-X-ray, iziqapha zenhliziyo, izisetshenziswa zokuskena ze-CAT, nemishini yokuhlola yezokwelapha, phakathi kokunye.

6. Ezempi Nokuvikela: Ithandwe ukuqina kwayo, ukusebenza kwayo, kanye nesisindo esilula, i-PCBS enezingqimba eziningi ingasetshenziswa kumasekhethi anesivinini esikhulu, esiba yinto ehamba phambili ebaluleke kakhulu ezicelweni zempi. Ziphinde zithandeke ngenxa yokuthanda ukukhula komkhakha wezokuvikela kumadizayini wobunjiniyela obumbene kakhulu, njengoba usayizi omncane we-PCBS enezingqimba eziningi unikeza isikhala esengeziwe kwezinye izingxenye ukwenza imisebenzi ekhona.

7. Izimoto: Ezikhathini zanamuhla, izimoto zithembele kakhulu ezintweni zikagesi, ikakhulukazi ngokukhuphuka kwezimoto zikagesi. Kusukela ku-GPS namakhompuyutha asebhodini kuya kumaswishi amalambu aphambili alawulwa nge-elekthronikhi nezinzwa zenjini, ukusebenzisa uhlobo olufanele lwezingxenye kubaluleka kakhulu ekwakhiweni kwemoto. Kungakho abakhiqizi bezimoto abaningi sebeqala ukuthanda i-PCBS ye-multilayer kunezinye izindlela. Nakuba zincane futhi ziqinile, i-PCBS enezingqimba eziningi nayo iyasebenza kakhulu futhi imelana nokushisa, okuyenza ilungele indawo yangaphakathi yemoto.

8. I-Aerospace: Njengezimoto, amajethi namarokhethi, ezikhathini zanamuhla kuthembele kakhulu emishinini kagesi, konke okufanele kucace kakhulu. Kusukela kumakhompuyutha asetshenziswa phansi kuya kulawo asendaweni yabasebenzi, izinhlelo zokusebenza ze-PCB zendiza kufanele zithembeke futhi zikwazi ukusingatha izingcindezi zokuhamba komoya kuyilapho zenza indawo eyanele yonke imishini ezungezile. Kulokhu, i-PCBS ye-multilayer inikeza isisombululo esihle, esinezingqimba eziningi zokuvikela ukuvimbela ukushisa nokucindezeleka kwangaphandle ekulimazeni uxhumano, futhi ziyakwazi ukwenziwa ngezinto eziguquguqukayo. Izinga eliphezulu nokusebenza kwabo nakho kunomthelela kulolu hlelo lokusebenza embonini ye-aerospace, njengoba izinkampani ze-aerospace zikhetha ukusebenzisa izinto ezingcono kakhulu zokugcina abasebenzi bazo kanye nemishini kuphephile.

9. Nokunye! I-Multilayer PCBS isetshenziswa kwezinye izimboni ezahlukahlukene, kufaka phakathi imboni yocwaningo lwesayensi ngisho nezinto zikagesi zasendlini nokuphepha. I-Multilayer PCBS isetshenziselwa yonke into kusukela kuma-alamu nezinzwa ze-fiber-optic kuya ku-athomu-smasher kanye nemishini yokuhlaziya isimo sezulu, kusizakala ngesikhala nokonga isisindo okunikezwa yile fomethi ye-PCB, kanye nezici zakhona ezithuthukisiwe.

imibuzo ejwayelekile ukubuzwa

Izinto ezehlukene ezisetshenziswa ekukhiqizeni ama-PCB anezingqimba eziningi amabhodi, ucwecwe lwethusi, isistimu ye-resin, i-substrate, i-vias, ishidi le-fiberglass elifakwe. Usebenzisa isemishi elishintshayo, ungakwazi laminate lezi zinto ndawonye.

Zonke izindiza zethusi zigxilile futhi ukucwenga kwawo wonke ama-vias angaphakathi kwenziwa ngaphambi kwezingqimba.

Ama-PCB amaningi afika nezinzuzo eziningi ezinhle. Ezinye zazo zihlanganisa:

Ukuminyana okuphezulu komhlangano

Ukuhlinzekwa kwejubane eliphezulu kanye nomthamo omkhulu, ngenxa yezakhiwo zabo zikagesi

Ukwehliswa kwesisindo samadivayisi

Ukuqedwa kwezixhumi ezidingekayo kuma-PCB amaningi ahlukene, ngaleyo ndlela kube lula ukwakhiwa kwawo.

Ama-PCB amaningi angasetshenziswa ezindaweni eziningi. Ake sicabangele ezinye zazo.

Asetshenziswa ekukhiqizeni i-CAT scan, iziqapha zenhliziyo, kanye nemishini yesimanje ye-x-ray.

Isetshenziselwa ukukhiqizwa kwamasekhethi anesivinini esikhulu ngenxa yokusebenza kwawo nokuqina

Isetshenziselwa amaswishi amalambu aphambili namakhompyutha angaphakathi ngenxa yokusebenza kwawo okuphezulu nekhono lokumelana nokushisa

Ukusebenza kwemishini kanye nesistimu yokulawula yezimboni kuyazisebenzisa ngenxa yobukhulu bazo kanye nokuqina kwazo.

Ama-electronics wabathengi njengama-microwaves nama-smartphones nawo asebenzisa ama-PCB anezingqimba eziningi ngenxa yobukhulu bawo obuncane nokusebenza kwawo.

Izinhlelo zesathelayithi, i-GPS, nolwazi lwesiginali, nakho kusebenzisa ama-PCB anezingqimba eziningi

Isetshenziswa ekukhiqizeni izinto zikagesi zekhompuyutha ezisetshenziswa kumaseva e-M ngenxa yokusebenza kwawo kanye nezibaluli zokonga isikhala.

Ungakwazi ukukhomba i-PCB ye-multilayer ngokusebenzisa okulandelayo

Ukuthi okokusebenza kwakho kwe-elekthronikhi kusebenza kanjani ngokushesha, kanye nesilungiselelo sokusebenza sebhodi esiphezulu

Ukucushwa, ukubalwa kongqimba, kanye nenani lesakhiwo sebhodi nakho kudlala indima ekuhlonzeni

Ukuminyana komzila webhodi

Umthamo wokusebenza, isivinini, amapharamitha, kanye nokusebenza, kuyahlukanisa uma i-PCB iyizendlalelo eziningi

Basebenzisa amasu okukhiqiza alula, kodwa basagxile ekusebenzeni kanye nekhwalithi.

Ama-PCB amaningi ajwayele ukuba nzima ukwenza isitayela, ngokungafani nalawo anesendlalelo esisodwa anenqubo yokukhiqiza elula

Ama-PCB anongqimba olulodwa ngokuvamile akhiqizwa ngobuningi futhi anga-odwa ngobuningi. Lokhu kusiza ekwehliseni intengo ibhodi ngalinye ngaleyo ndlela kuqinisekiswe ukuthi ukukhiqiza lawa madivaysi kubiza kancane. Kuma-PCB anezingqimba eziningi, ukuwakhiqiza kuvame ukuyisicefe, futhi kungase kube nzima ukuwakhiqiza ngezimfanelo ezinkulu ngesikhathi esisodwa.

Izingxenye ze-PCB zifaka:

I-Led: I-Led ivumela ukugeleza kwamanje ngendlela

I-Capacitor: Yenziwe ngeshaji kagesi

I-Transistor: Isetshenziselwa ukukhulisa amandla

Ama-Resistors: Kuyasiza ekulawuleni amandla kagesi uma udlula

I-Diode: Ama-Diode avumela ukudlula kwamandla ngendlela eyodwa kuphela

Ibhethri: inika isekethe i-voltage yayo

I-Hydraulic press: Lokhu kuqinisekisa ukuthi izinto zensimbi ziguqulwa zibe amashidi ensimbi. Lokhu kusiza ngesikhathi sokuncipha lapho wenza impushana yengilazi, kanye nokwenza amaphilisi.

Prepreg: Lena into ebalulekile esetshenziswa kumabhodi ezendlalelo eziningi. Basiza ekubambeni ama-cores ndawonye. Ama-prepregs akhiwe nge-fiberglass, efakwe ku-epoxy-based material eyaziwa ngokuthi i-resin. Izendlalelo zayo zihlangene ezingeni lokushisa elithile. Lokhu kusiza ekudaleni ukujiya kwebhodi elithile.

Ama-PCB amaningi asetshenziswa kabanzi ngenxa yalezi zizathu ezilandelayo:

Ama-PCB amaningi enziwa kusetshenziswa ubuchwepheshe obuphezulu. Yingakho ithenjwa kakhulu ngenxa yamakhono, izinqubo, kanye nemiklamo edingekayo ukuze yenziwe.

Ungakwazi futhi ukukubalela eqinisweni lokuthi abasebenzisi bahlala befuna into yesimanjemanje.

Ubukhulu bayo obuncane buyenza ikwazi ukuguquguquka

Inosayizi omncane, futhi ukusebenza kwayo kuthuthukiswa ngobuchwepheshe bayo. Abasebenzisi abaningi bakhetha idivayisi enosayizi omncane

Ngenxa yesisindo sayo esincane, iyaphatheka ngokwanele futhi ilungele abasebenzisi. Abasebenzisi bangathwala kalula, ngoba abanamandla njengamanye ama-smartphones.

Ngenxa yenqubo yokwenziwa kwayo, abasebenzisi babheka le PCB njengenekhwalithi ephezulu

Isebenzisa ochwepheshe abanamakhono aphezulu, ubuchwepheshe besimanje, nezinto ezisezingeni eliphezulu.

Ukufakwa kalula, okwenza kusetshenziswe kabanzi, ngakho-ke asikho isidingo sokuthola isevisi ngaphandle

Ama-PCB ama-Multilayer afika nesendlalelo esivikelayo, esivimbela umonakalo ukuthi ungafiki kuwo, kanye nokwanda kokuqina kwawo.

Iyona ekhethwa kakhulu ngenxa yokuminyana kwayo okuphezulu, uma iqhathaniswa nozakwabo. Abasebenzisi bathanda amadivayisi anesisindo esiphezulu ngedigri yevolumu ngayinye, okufanele iziqhayise ngesikhala sokugcina esanele.

I-Multilayer PCB iza namazinga athile ekhwalithi. Zihlanganisa

I-ISO 9001 iqinisekisa ukuthi abakhiqizi bahlangabezana nezidingo zamakhasimende ngaphakathi kwezidingo ezilawulwayo nezivunyelwe ezithinta isevisi noma umkhiqizo.

I-ATF16949 ingelinye izinga lekhwalithi elidinga abakhiqizi bezinto zikagesi ukuthi baqinisekise ukuphepha nekhwalithi yemikhiqizo yezimoto. Lokhu kusiza ekuthuthukiseni ukwethembeka nokusebenza kwezingxenye zezimoto.

Isevisi yokufakwa kuhlu kwe-UL idinga ukuthi abakhiqizi bahlole imikhiqizo yabo kahle. Lokhu kwenzelwa ukwenza isiqiniseko sokuthi izidingo ezithile ziyahlangatshezwa.

Yebo, ama-PCB anezinhlaka eziningi ahlukaniswe ngaphansi kwama-HF PCB. Ngezendlalelo eziningi, amabhodi angaba ne-coefficient enkulu yokushisa kanye nokulawulwa kwe-impedance.

Ukuze kubhekwe phakathi kwezicelo zokuklama ama-high-frequency, ukuba nendiza ephansi kubaluleke kakhulu. Izinhlelo zokusebenza ze-Multilayer zisetshenziswa ezinhlelweni zefrikhwensi ephezulu njengama-smartphones nama-microwaves.

Ingakhiqizwa embonini ye-PCB. Ibhodi le-4layers ngokuvamile lisebenzisa i-core ene-foil eyodwa yethusi ohlangothini ngalunye kanye nebhodi le-3layers eline-foil eyodwa yethusi ohlangothini olulodwa. Kumele zicindezelwe ndawonye.

Umehluko wezindleko zenqubo phakathi kwalokhu okubili ukuthi ibhodi elinezingqimba ezine linecwecwe elilodwa lethusi nesendlalelo sokubopha. Umehluko wezindleko awubalulekile. Uma imboni ye-PCB yenza i-quote, ngokuvamile icashunwa ngokwenani elilinganayo. Futhi, izendlalelo ezi-3-4 zivame ukucashunwa njengebanga. (Isibonelo:Uma uklama ibhodi elinezingqimba ezi-5, elinye iqembu lizocaphuna ngentengo yebhodi le-6layers. Okusho ukuthi, intengo oyiklama izendlalelo ezi-3 iyafana nenani oliklamayo lezendlalelo ezi-4. )

Kuthekhnoloji yenqubo ye-PCB, ibhodi le-PCB elinezingqimba ezine lilawulwa kangcono kunebhodi elinezingqimba ezintathu, ikakhulukazi ngokwe-symmetry. I-warpage yebhodi enezingqimba ezine ingalawulwa ngaphansi kwe-0.7%, kodwa ubukhulu bebhodi lezendlalelo ezintathu likhulu. Ngaleso sikhathi, i-warpage izodlula leli zinga, elizothinta ukwethembeka komhlangano we-SMT nawo wonke umkhiqizo. Ngakho-ke, umklami akufanele aklame ibhodi lesendlalelo elinezinombolo ezingavamile. Noma ngabe ungqimba olunenombolo eyinqaba ludingeka, luzoklanywa njengesendlalelo esinezinombolo ezingelona iqiniso. Okusho ukuklama izingqimba ezi-5 zibe izingqimba eziyisi-6 nezingu-7 zibe izingqimba eziyisi-8.

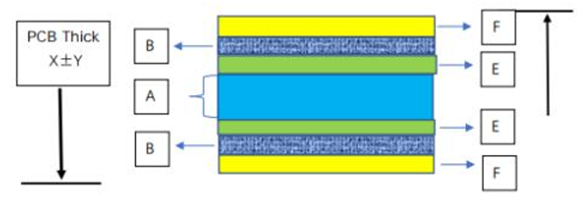

A: Ukujiya kwesendlalelo sangaphakathi

E: Ukujiya kwefoyili yethusi yangaphakathi

X: Ugqinsi lwebhodi eliqediwe

B: Ubukhulu beshidi le-PP

F: Ubukhulu befoyili yethusi yangaphandle

Y: Iqedile ukubekezelela i-PCB

1.Bala umkhawulo ongaphezulu nophansi wokucindezela:

Ngokuvamile ipuleti likathayela: umkhawulo ophezulu -6MIL, umkhawulo ophansi-4MIL

Ipuleti legolide: umkhawulo ophezulu -5MIL, umkhawulo ophansi -3MIL

Isibonelo, ipuleti likathayela: umkhawulo ophezulu=X+Y-6MIL umkhawulo ophansi=XY-4MIL

Bala i-median = (umkhawulo ophezulu + umkhawulo ophansi)/2

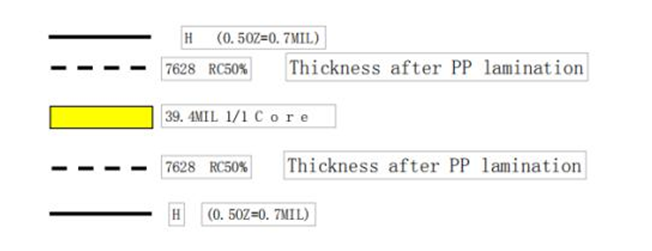

≈A+indawo yongqimba lwesibili lwefoyili yethusi%*E+indawo yoqweqwe lwensimbi yethusi%*E+B*2+F*2

Impahla yokusika yangaphakathi yebhodi elivamile elinezingqimba ezine lincane ngo-0.4mm kunebhodi eliqediwe, lisebenzisa ishidi elilodwa elingu-2116 PP ukucindezela. Ukuze uthole ugqinsi olukhethekile lwe-copper yangaphakathi kanye nogqinsi lwe-copper yangaphandle engaphezu kwe-1OZ, ubukhulu bethusi kufanele bucatshangelwe lapho kukhethwa ungqimba lwangaphakathi.

2. Bala ukubekezelelana okucindezelayo:

Umkhawulo ophezulu = Ukuqina kwebhodi okuqediwe + Kuqediwe inani lokubekezelela ku-inthanethi - [Plating yethusi ukujiya, ukujiya kawoyela oluhlaza

(Okuvamile 0.1MM)]-Ugqinsi olubalwe ngokomqondo ngemva kokucindezela

Umkhawulo ophansi = ibhodi eliqediwe ukujiya-umkhiqizo oqediwe inani lokubekezelela ngaphandle komugqa- [I-Electroplating yethusi ukujiya, ukujiya kwezinhlamvu zikawoyela oluhlaza

(Okuvamile okungu-0.1MM)]-Ugqinsi olubalwa ngokomqondo ngemva kokucindezela

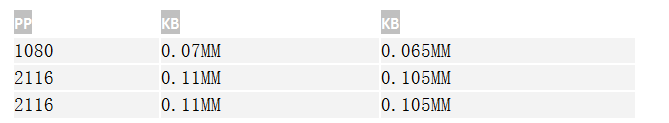

3.Izinhlobo ezijwayelekile zamashidi we-pp

Ngokuvamile, ungasebenzisi amashidi amabili e-PP anokuqukethwe okuphezulu kwe-resin ndawonye. Uma ungqimba lwangaphakathi lwethusi luncane kakhulu, sicela usebenzise amashidi e-PP anokuqukethwe okuphezulu kwe-resin. Amashidi angu-1080 PP anobukhulu obuphezulu kanye nokuqukethwe kwe-resin ephansi. Ungacindezeli ishidi elilodwa ngangokunokwenzeka. Amashidi ama-2 kuphela we-2116 kanye ne-7630 PP amashidi angacindezelwa kumapuleti ethusi aminyene ngaphezu kwe-2OZ. Isendlalelo asikwazi ukucindezelwa ishidi elilodwa le-PP. Ishidi le-7628 PP lingacindezelwa ishidi elilodwa, amashidi ama-2, amashidi ama-3, noma amashidi angama-4.

Incazelo yokubala kogqinsi kwethiyori yebhodi le-PCB lezendlalelo eziningi ngemva kokucindezela

Ukuqina ngemva kwe-PP lamination = 100% ugqinsi lwethusi olusele lwe-100%-ugqinsi lwethusi lwangaphakathi*(1-Izinga lethusi elisele%)

Njengegama, ama-PCB anezingqimba eziningi ayinhlanganisela yamasekhethi ezendlalelo eziningi. Inani lama-PCB anohlangothi olulodwa nahlangothi olukabili ahlanganiswa futhi ahlukaniswe into evikelayo (efana ne-dielectric) ukuze kwakheke i-PCB ye-multilayer yalo mklamo oyinkimbinkimbi. Yandisa inani lezendlalelo futhi ikhulise indawo etholakalayo yokufaka izintambo.

Inani lezendlalelo ze-conductive phakathi kwezinto zokuvikela okungenani zingu-3, futhi kufika ku-100. Ngokuvamile sinezendlalelo ezingu-4 kuya kwezingu-12, isibonelo, ama-smartphones ngokuvamile ayizendlalelo ezingu-12. Inani elikhulu lezendlalelo lizenza zifanelekele ubunzima bohlelo lokusebenza. Abakhiqizi bancamela ngisho nezendlalelo ngoba ukubeka inani eliyinqaba lezendlalelo kungenza isekethe ibe yinkimbinkimbi futhi ibe yinkinga.

Ama-PCB amaningi aqinile ngokujwayelekile ngoba kunzima ukuthi i-PCBS eguquguqukayo ifinyelele izendlalelo eziningi. Ama-PCB ezendlalelo eziningi eziqinile adinga ukubhola ukuze kuxhunywe izingqimba ezihlukene. Izimbobo ezijwayelekile zingamosha indawo, ngakho-ke kusetshenziswa izimbobo ezigqitshiwe noma ezingaboni emehlweni, ezingena kuphela ezingqimbeni ezidingekayo. Izendlalelo ezihlukene zingahlukaniswa zibe izindiza ezihlukene, njengendiza yaphansi, indiza yamandla, nendiza yesignali.

Uma ufuna ukwakha i-PCB, kunezinhlobonhlobo zezinto ongakhetha kuzo, njenge-ceramics ekhethekile, i-epoxy plexiglass. I-resin ne-binder materials ihlanganisa izingxenye kanye nezendlalelo ezahlukene ndawonye. I-Relaminating, eyenziwa emazingeni okushisa aphezulu nezingcindezi, isusa noma imuphi umoya ovaleleke phakathi kwezendlalelo futhi kusiza ukuncibilikisa izendlalelo ezihlukene zangaphambi kokulungiselela kanye nezendlalelo eziyinhloko.