Isivinini esiphezulu sokuhlolwa kokulahlekelwa kokufaka kwe-PCB POFV enepig| YMSPCB

Iyini i-High Speed PCB?

"Ijubane Eliphezulu" ngokuvamile lihunyushwa ngokuthi lisho amasekhethi lapho ubude bonqenqema olukhuphukayo noma owehlayo lwesignali lungaphezu kwengxenye eyodwa kwesithupha yobude bomugqa wokudlulisela omkhulu kunobude bomugqa wokudlulisela, bese ubude bomugqa wokudlulisela bubonisa ukuziphatha kolayini obambene.

Ku- PCB enesivinini esikhulu , isikhathi sokukhuphuka sishesha ngokwanele kangangokuthi umkhawulokudonsa wesiginali yedijithali ungadlulela kumafrikhwensi aphezulu e-MHz noma e-GHz. Uma lokhu kwenzeka, kunezinkinga ezithile zokusayina ezizoqashelwa uma ibhodi lingaklanywanga kusetshenziswa imithetho yokuklama ye-PCB enesivinini esikhulu. Ikakhulukazi, umuntu angase aqaphele:

1. Ukukhala kwesikhashana okukhulu ngendlela engamukelekile. Lokhu ngokuvamile kwenzeka lapho ukulandelelwa kungabanzi ngokwanele, nakuba udinga ukuqaphela lapho wenza ukulandelelwa kwakho kube banzi (bona isigaba ku-Impedance Contorl ku-PCB Design ngezansi). Uma ukukhala kwesikhashana kukukhulu impela, uzoba ne-overshoot enkulu noma i-undershoot ezinguqukweni zakho zesignali.

2.I-crosstalk eqinile. Njengoba isivinini sesignali sikhula (okungukuthi, njengoba isikhathi sokukhuphuka sincipha), i-capacitive crosstalk ingaba nkulu kakhulu njengoba isipiliyoni samanje esibangelwa yi-capacitive impedance.

3.Ukuboniswa kwezingxenye zomshayeli nomamukeli. Amasignali akho angabonisa ngaphandle kwezinye izingxenye noma nini lapho kunokungafani kokuphazamiseka. Ukuthi ukungafani kwe-impedance kubaluleka noma cha kudinga ukuthi kubhekwe okokufaka, i-impedance yokulayisha, kanye nesici somugqa wokudlulisa wesici soxhumano. Ungafunda kabanzi ngalokhu esigabeni esilandelayo.

4.Izinkinga zobuqotho bamandla (i-PDN enyakazayo, i-ground bounce, njll.). Lena enye isethi yezinkinga ezingagwemeki kunoma yimuphi umklamo. Kodwa-ke, i-PDN enyakazayo kanye nanoma iyiphi i-EMI ewumphumela ingancishiswa ngokuphawulekayo ngomklamo ofanele wokupakisha nezindlela zokuhlukanisa. Ungafunda kabanzi mayelana nedizayini yesitaki ye-PCB enesivinini esikhulu ngokuhamba kwesikhathi kulo mhlahlandlela.

5.I-EMI eqinile eyenziwe futhi esakazwayo. Ucwaningo lokuxazulula izinkinga ze-EMI lubanzi, kokubili ezingeni le-IC kanye nezinga lokuklama le-PCB elinesivinini esikhulu. I-EMI empeleni iyinqubo ehambisanayo; uma uklama ibhodi lakho ukuthi libe ne-EMI immunity eqinile, izokhipha i-EMI encane. Futhi, okuningi kwalokhu kubilisa ekuklameni isitaki se-PCB esifanele.

Ama-PCB anemvamisa ephezulu ngokuvamile ahlinzeka ngebanga lefrikhwensi ukusuka ku-500MHz ukuya ku-2 GHz, elingahlangabezana nezidingo zemiklamo ye-PCB enesivinini esikhulu, i-microwave, i-radiofrequency, nezinhlelo zokusebenza zeselula. Uma imvamisa ingaphezulu kuka-1 GHz, singayichaza njengefrikhwensi ephezulu.

Ubunkimbinkimbi bezingxenye ze-elekthronikhi namaswishi bulokhu bukhula njalo kulezi zinsuku futhi budinga amazinga okugeleza kwesignali asheshayo. Ngakho-ke, amaza okudlulisela aphezulu ayadingeka. Ama-PCB anemvamisa ephezulu asiza kakhulu lapho ehlanganisa izimfuneko zesignali ezikhethekile ezingxenyeni ze-elekthronikhi nemikhiqizo enezinzuzo ezifana nokusebenza kahle okuphezulu, nesivinini esisheshayo, ukuncipha okuphansi, kanye nezakhiwo ze-dielectric ezingaguquki.Okunye ukucatshangelwa kwemiklamo ye-PCBs

Ama-PCB anemvamisa ephezulu asetshenziswa kakhulu ezinhlelweni zomsakazo kanye nesivinini esikhulu sedijithali, njengokuxhumana okungenantambo kwe-5G, izinzwa ze-radar yezimoto, i-aerospace, amasathelayithi, njll. Kodwa kunezici eziningi ezibalulekile okufanele zicatshangelwe lapho kukhiqizwa ama-PCBs anemvamisa ephezulu.

· Idizayini enezingqimba eziningi

Ngokuvamile sisebenzisa ama -PCB anezendlalelo eziningi kumiklamo ye-PCB yemvamisa ephezulu. Ama-PCB anezendlalelo eziningi anobuningi bomhlangano kanye nevolumu encane, okuwenza afaneleke kakhulu kumaphakheji omthelela. Futhi amabhodi anezingqimba eziningi alungele ukufinyeza ukuxhumana phakathi kwezingxenye ze-elekthronikhi futhi athuthukise isivinini sokudluliswa kwesignali.

Ukuklama indiza ephansi kuyingxenye ebalulekile yezinhlelo zokusebenza zemvamisa ephezulu ngoba akugcini nje ngokugcina ikhwalithi yesignali kodwa futhi kusiza ukunciphisa imisebe ye-EMI.Ibhodi lefrikhwensi ephezulu yezinhlelo zokusebenza ezingenantambo kanye namazinga edatha ebangeni eliphezulu le-GHz anezidingo ezikhethekile kumpahla esetshenzisiwe:

1. Imvume eguquliwe.

2.Ukuncishiswa okuphansi kokudluliswa kwesignali okuphumelelayo.

Ukwakhiwa kwe-3.Homogeneous ngokubekezelelana okuphansi ku-insulation thickness kanye ne-dielectric constant. Isidingo semikhiqizo ye-PCB enemvamisa ephezulu kanye nesivinini esikhulu sikhuphuka ngokushesha kulezi zinsuku. Njengomkhiqizi we- nomkhiqizi PCB , i-YMS igxile ekuhlinzekeni amakhasimende nge-PCB prototyping esezingeni eliphezulu ethembekile enekhwalithi ephezulu. Uma unezinkinga ngokuklama kwe-PCB noma ukukhiqizwa kwe-PCB, sicela ukhululeke ukuxhumana nathi.

| Uhlolojikelele lwamakhono okukhiqiza we-YMS High Speed PCB | ||

| Isici | amakhono | |

| Isendlalelo | 2-30L | |

| Iyatholakala Ijubane eliphezuluPCB Technology | Ngembobo nge-Aspect Ratio 16: 1 | |

| wangcwatshwa futhi uyimpumputhe nge | ||

| I-Mixed Dielectric Boards ( High Speed Izinto + FR-4 izinhlanganisela) | ||

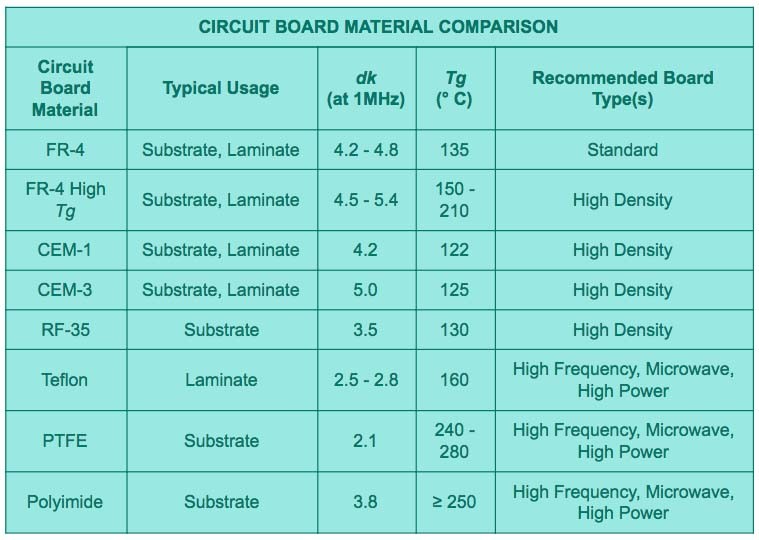

| Ifanele Ijubane eliphezuluIzinto etholakalayo: M4, M6 chungechunge, N4000-13 chungechunge, FR408HR, TU862HF TU872SLKSP, EM828, njll | ||

| I-Tight Etch Tolerances Ezicini Ezibalulekile Ze-RF:+/- .0005″ ukubekezelela okujwayelekile kwethusi elingu-0.5oz elingagxiliwe | ||

| Ukwakhiwa komgodi we-Multilevel, Izinhlamvu zemali ze-Copper nama-slugs, i-Metal Core & Metal Back, ama-laminates aphethwe yi-Thermally, i-Edge Plating, njll. | ||

| Ubukhulu | 0.3mm-8mm | |

| Ubuncane bomugqa nobubanzi | 0.075mm/0.075mm(3mil/3mil) | |

| IBGA PITCH | 0.35mm | |

| Min laser Usayizi yamba | 0.075mm (3nil) | |

| Min mechanical Usayizi yamba | 0.15mm (6mil) | |

| Isilinganiselo se-laser hole | 0.9: 1 | |

| Isilinganiselo se-Aspect for through hole | 16: 1 | |

| I-Surface Qeda | Ifanele Ijubane eliphezuluPCB urface kuphela: Electroless Nickel, Babecwiliswa Igolide, ENEPIG, Lead HASL khulula, Babecwiliswa Isiliva | |

| NgeNketho Yokugcwalisa | I-via iyagcotshwa futhi igcwaliswe nge-epoxy eqhuba noma engeyona eye-conductive bese igoqelwa futhi yambozwa ngaphezulu (i-VIPPO) | |

| Ithusi lagcwaliswa, kwagcwaliswa isiliva | ||

| I-Laser nge-plated ivaliwe | ||

| Ukubhalisa | ± 4mil | |

| Isifihla Solder | Okuluhlaza okotshani, obomvu, ophuzi, ohlaza okwesibhakabhaka, omhlophe, omnyama, onsomi, uMatte Mnyama, uMatte oluhlaza. | |

Funda kabanzi ngemikhiqizo ye-YMS

Ividiyo