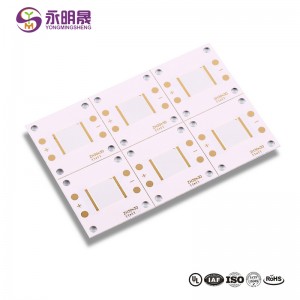

Umgogodla wensimbi enamacala amabili pcb I-Copper Base High Power Metal core Board| I-YMS PCB

Iyini i-Multi Layers MCPCB?

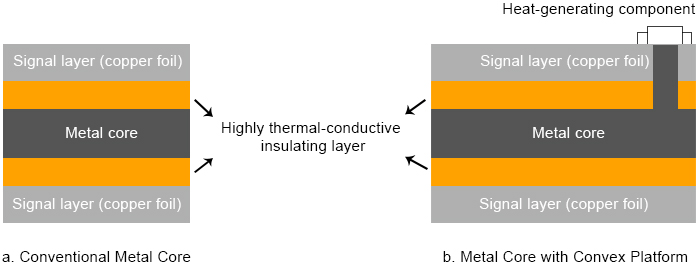

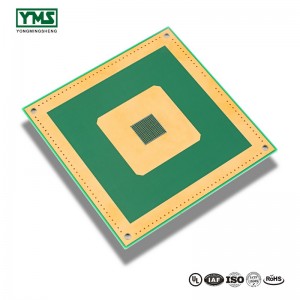

I- Metal Core Printed Circuit Board (MCPCB) , eyaziwa nangokuthi i- PCB eshisayo noma i-PCB esekelwe insimbi, iwuhlobo lwe-PCB enezinto zensimbi njengesisekelo sayo sengxenye yesisakazeli sokushisa sebhodi. Insimbi ewugqinsi (ehlala i-aluminium noma ithusi) ivala uhlangothi olu-1 lwe-PCB. I-Metal core ingaba inkomba yensimbi, ibe phakathi nendawo endaweni ethile noma ngemuva kwebhodi. Injongo yomgogodla we-MCPCB ukuqondisa kabusha ukushisa kude nezingxenye zebhodi ezibalulekile futhi kuya ezindaweni ezingabalulekile kangako njenge-metal heatsink backing noma i-metallic core. Izinsimbi eziyisisekelo ku-MCPCB zisetshenziswa njengenye indlela yamabhodi e-FR4 noma e-CEM3.

Ibhodi lesifunda eliphrintiwe eliwumgogodla wensimbi (MCPCB) elibuye laziwe nge-thermal PCB, lihlanganisa into yensimbi njengesisekelo salo ngokuphambene ne-FR4 evamile, yocezu lwesisababi sokushisa sebhodi. Ukushisa kwakha ngenxa yezingxenye ezithile ze-elekthronikhi ngesikhathi sokusebenza kwebhodi. Inhloso yensimbi ukuguqula lokhu kushisa kude nezingxenye zebhodi ezibucayi futhi kuye ezindaweni ezingabalulekile kangako njenge-metal heatsink backing noma i-metallic core. Ngakho-ke, lawa ma-PCB afanele ukuphathwa kwe-thermal.

Ku-MCPCB yezendlalelo eziningi, izendlalelo zizosatshalaliswa ngokulinganayo ohlangothini ngalunye lwengqikithi yensimbi. Isibonelo, ebhodini elinezingqimba eziyi-12, umgogodla wensimbi uzoba phakathi nendawo enezingqimba ezi-6 phezulu nezingu-6 phansi.

Ama-MCPCB aphinde abizwe ngokuthi yi-insulated metallic substrate (IMS), i-PCB yensimbi engafakwanga (IMPCB), ama-PCB agqoke okushisayo, nama-PCB agqoke insimbi. Kulesi sihloko, sizobe sisebenzisa isifinyezo esithi MCPCB ukugwema ukungaqondakali.

Ama-MCPCB akhiwe ngezingqimba ezivikela ukushisa ezishisayo, amapuleti ensimbi, kanye necwecwe lensimbi lethusi. Eminye imihlahlandlela/izincomo zokuklama kwamabhodi Esifunda Aphrintiwe We-Metal Core (Aluminium Nethusi) iyatholakala uma icelwa; thintana ne-YMSPCB kokuthi kell@ymspcb.com.noma Omele Ukuthengisa ukuze ubuze kabanzi.

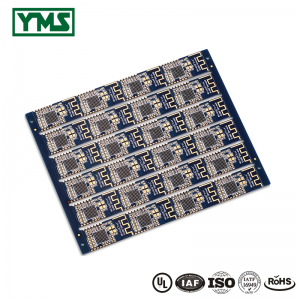

I-YMS Multi Layers I-Metal core PCB amakhono okukhiqiza:

| Uhlolojikelele lwamakhono okukhiqiza we-YMS Multi Layers Metal PCB | ||

| Isici | amakhono | |

| Isendlalelo | 1-8L | |

| base Material | I-Aluminium/Copper/Iron Alloy | |

| Ubukhulu | 0.8 mm imiz | |

| Uhlamvu lwemali Ukushuba | 0.8-3.0mm | |

| Ubuncane bomugqa nobubanzi | 0.05mm / 0.05mm (2mil / 2mil) | |

| IBGA PITCH | 0.35mm | |

| Imali yokuthengisa ye Min Copper | 1.0mm iminithi | |

| Min mechanical Usayizi yamba | 0.15mm (6mil) | |

| Isilinganiselo se-Aspect for through hole | 16: 1 | |

| I-Surface Qeda | I-HASL, iholele mahhala i-HASL, i-ENIG, ukucwiliswa kweTin, i-OSP, ukucwiliswa kwesiliva, umunwe wegolide, i-Electroplating Hard Gold, i-OSP ekhethiwe, ENEPIG.etc | |

| NgeNketho Yokugcwalisa | I-via iyagcotshwa futhi igcwaliswe nge-epoxy eqhuba noma engeyona eye-conductive bese igoqelwa futhi yambozwa ngaphezulu (i-VIPPO) | |

| Ithusi lagcwaliswa, kwagcwaliswa isiliva | ||

| Ukubhalisa | ± 4mil | |

| Isifihla Solder | Okuluhlaza okotshani, obomvu, ophuzi, ohlaza okwesibhakabhaka, omhlophe, omnyama, onsomi, uMatte Mnyama, uMatte oluhlaza. | |

Izizathu eziyinhloko zokusebenzisa amabhodi esisekelo sethusi

1. Ukukhipha ukushisa okuhle:

Njengamanje, amabhodi amaningi we- 2 layer kanye namabhodi amaningi anenzuzo yokuminyana okuphezulu namandla aphezulu, kodwa ukukhishwa kokushisa kunzima ukuba. Izinto eziyisisekelo ze-PCB ezijwayelekile ezifana ne-FR4, i-CEM3 i-conductor empofu yokushisa, ukwahlukanisa kuphakathi kwezendlalelo, futhi ukukhishwa kokushisa akukwazi ukuphuma. Ukushisisa kwendawo yezinto zikagesi akukwazi ukuqedwa kuzoholela ekuhlulekeni kwezinga lokushisa eliphezulu kwezingxenye ze-elekthronikhi. Kodwa ukusebenza okuhle kokukhipha ukushisa kwe-metal core PCB kungaxazulula le nkinga yokukhipha ukushisa.

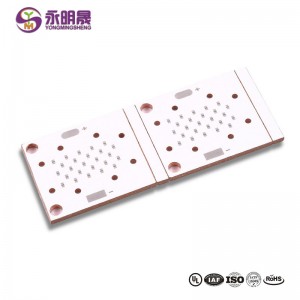

2. Ukuzinza kwe-Dimensional:

I-Metal core PCB ngokusobala izinzile ngosayizi kunamabhodi aphrintiwe wezinto zokuvikela. Ibhodi le- Aluminium base board kanye ne-aluminium sandwich board iyashisisa ukusuka ku-30℃ kuya ku-140~150℃, usayizi wayo ushintsha ngo-2.5~3.0%.

3. Enye imbangela:

Ibhodi lesisekelo se-Copper linomphumela wokuvikela futhi lithatha indawo ye-substrate ye-ceramic ephukayo, ngakho-ke ingaqiniseka ukusebenzisa ubuchwepheshe bokukhweza phezulu ukuze kuncishiswe indawo yangempela esebenza ngempumelelo ye-PCB. Ibhodi lesisekelo sethusi lithatha indawo yerediyetha nezinye izakhi, lithuthukisa ukumelana nokushisa nokusebenza ngokomzimba kwemikhiqizo futhi linciphisa izindleko zokukhiqiza nezindleko zabasebenzi.

Ungase uthande:

1. Izici zohlelo lokusebenza lwe-aluminium PCB

2. Inqubo yokuhlanganisa i-Copper ye-PCB yangaphandle (PTH)

3, I-Copper clad plate kanye ne-aluminium substrate umehluko omkhulu

Funda kabanzi ngemikhiqizo ye-YMS