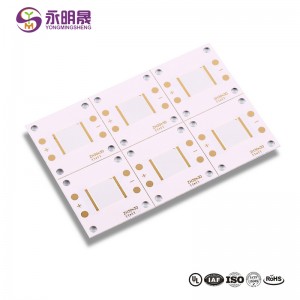

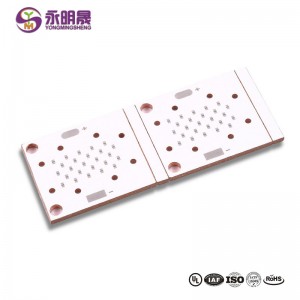

I-Ceramic PCB ye-ceramic eyodwa nezinhlangothi ezimbili I-PCB yenza ama-Ceramic Substrates| I-YMS PCB

I-Ceramic PCB: ibhodi lesifunda se-ceramic substrate

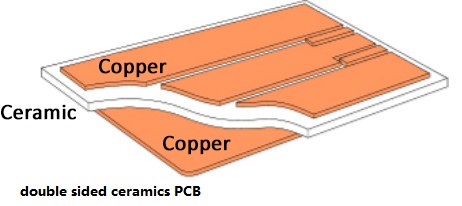

I- Ceramic Substrate ichaza ibhodi lenqubo eliyingqayizivele lapho ucwecwe lwe-aluminium yethusi lubambelele ngokuqondile endaweni (uhlangothi olulodwa noma olukabili) lwe-alumina (Al2O3) noma i-aluminium nitride (AlN) engasindi ye-ceramic substrate lapho kushisa. Uma iqhathaniswa ne-FR-4 ejwayelekile noma i-aluminium substrate enesisindo esilula, i-substrate eyinhlanganisela ye-ultra-mncane eyenziwe inamandla akhethekile okufakwa kukagesi, ukuguquguquka okuphezulu kwe-thermal, ukuthengiswa okukhethekile okuthambile kanye nokuqina kwebhondi ephezulu, futhi ingaqoshwa ihluzo eziningi njenge-PCB, kumnandi ekhona lugging ikhono. Ilungele izinto ezinesizukulwane esishisayo (i-LED ekhanya kakhulu, amandla elanga), kanye nokumelana nesimo sezulu esihle kakhulu kungcono kumasethingi angaphandle amabi. I-Ceramic Circuit Board Technology Isingeniso

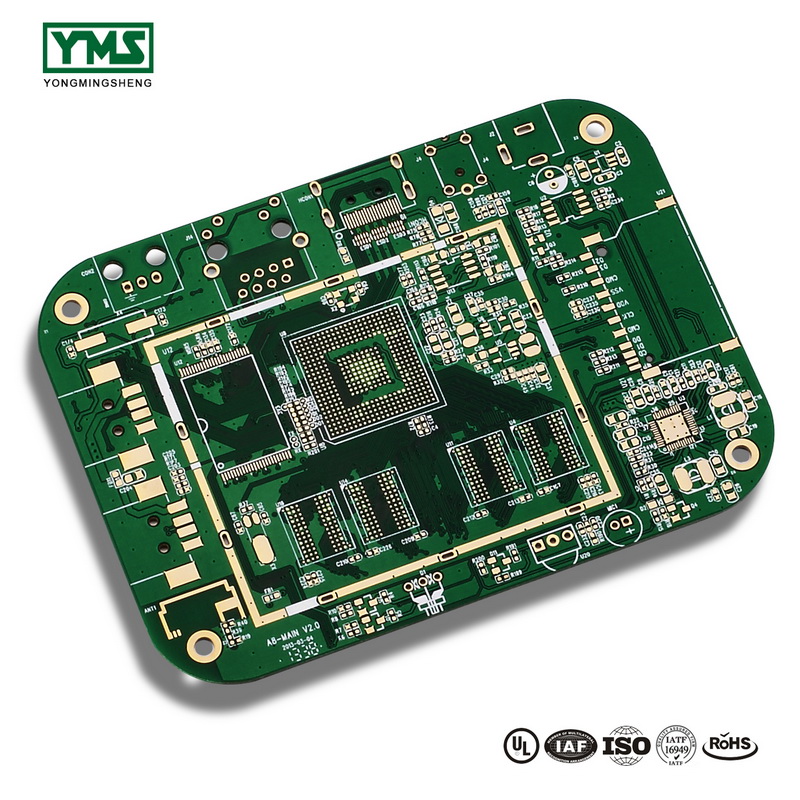

Kungani usebenzise izinto ze-ceramics ukukhiqiza amabhodi wesifunda? Amabhodi wesifunda se-Ceramic enziwe nge-ceramics kagesi futhi angenziwa ngezindlela ezihlukahlukene. Izici zokumelana nokushisa okuphezulu kanye nokufakwa kukagesi okuphezulu kwamabhodi wesifunda se-ceramic yizona ezivelele kakhulu. Izinzuzo zokungaguquguquki kwe-dielectric ephansi kanye nokulahlekelwa kwe-dielectric, ukuqhutshwa kokushisa okuphezulu, ukuzinza okuhle kwamakhemikhali, kanye ne-coefficient yokwandisa ukushisa okufanayo ezingxenyeni nakho kubalulekile. Ukukhiqizwa kwamabhodi wesifunda se-ceramic kuzosebenzisa ubuchwepheshe be-LAM, okuwubuchwepheshe be-laser quick activation metallization. Asetshenziswa emkhakheni we-LED, amamojula anamandla amakhulu we-semiconductor, iziqandisi ze-semiconductor, ama-heaters kagesi, amasekhethi okulawula amandla, amasekhethi ahlanganisiwe wamandla, izingxenye zamandla ahlakaniphile, izinsiza zamandla ezishintshashintshayo ezihamba phambili, ukudluliselwa kombuso okuqinile, ugesi wezimoto, ukuxhumana, i-aerospace, kanye nezingxenye ze-electronics zempi.

Izinzuzo ze-Ceramic PCB

Ngokungafani ne-FR-4 yendabuko, izinto ze-ceramic zinokusebenza okuhle kwe-high-frequency kanye nokusebenza kukagesi, zine-conductivity ephezulu ye-thermal, ukuqina kwamakhemikhali, ukuqina okuhle kakhulu kwe-thermal, nezinye izakhiwo ezingenayo i-organic substrates. Kuyinto entsha efanelekile yokupakisha ukukhiqizwa kwamasekhethi amakhulu ahlanganisiwe namamojula we-electronic wamandla.

Izinzuzo Main:

Higher conductivity ezishisayo.

Okufanayo okwengeziwe kwe-coefficient yokwandisa okushisayo.

Ibhodi lesifunda lensimbi eliqinile neliphansi le-alumina ceramic.

I-solderability ye-substrate yinhle, futhi izinga lokushisa lokusetshenziswa liphezulu.

I-insulation enhle.

Ukulahleka kwe-high-frequency ephansi.

Ukuhlanganiswa okuphezulu kakhulu kungenzeka.

Ayiqukethe izithako zemvelo, imelana nemisebe ye-cosmic, inokwethenjelwa okuphezulu emkhathini, futhi inempilo ende yesevisi.

Ungqimba lwethusi aluqukethe ungqimba lwe-oxide futhi lungasetshenziswa isikhathi eside endaweni yokunciphisa. Ama-Ceramic PCB angaba wusizo futhi asebenze kahle kumabhodi esekethe aphrintiwe kulezi zimboni nezinye eziningi, kuye ngedizayini yakho nezidingo zokukhiqiza.

I-Ceramic PCB iwuhlobo lokushisa oluqhuba i-ceramic powder kanye ne-organic binder, kanye ne-heat conduction organic ceramic PCB ilungiselelwa ekushiseni okushisayo okungu-9-20W/m. Ngamanye amazwi, i-ceramic PCB iyibhodi lesifunda eliphrintiwe elinesisekelo se-ceramic material, okuyizinto ezithinta ukushisa kakhulu ezifana ne-alumina, i-aluminium nitride, kanye ne-beryllium oxide, engenza umphumela osheshayo ekudluliseni ukushisa kude nezindawo ezishisayo futhi zilahle. phezu kobuso bonke. Ngaphezu kwalokho, i-ceramic PCB yakhiwe ngobuchwepheshe be-LAM, okuwubuchwepheshe obusebenzisa i-laser rapid activation metallization. Ngakho-ke i-ceramic PCB iguquguquka kakhulu engathatha indawo yalo lonke ibhodi lesifunda eliphrintiwe elingokwesiko elinokwakhiwa okungenzima kangako nokusebenza okuthuthukisiwe.

Ngaphandle kwe- MCPCB , uma ufuna ukusebenzisa i-PCB ekucindezelweni okuphezulu, ukwahlukanisa okuphezulu, imvamisa ephezulu, izinga lokushisa eliphezulu, kanye nemikhiqizo ye-elekthronikhi enokwethenjelwa ephezulu nencane, i-Ceramic PCB izoba yisinqumo sakho esingcono kakhulu.

Kungani i-Ceramic PCB inokusebenza okuhle kakhulu? Ungaba nombono omfushane ngesakhiwo sawo esiyisisekelo futhi uzoqonda.

- 96% noma 98% Alumina (Al2O3), Aluminium Nitride (ALN), noma i-Beryllium Oxide (BeO)

- Izinto zamakhondatha: Kubuchwepheshe befilimu emincane, ewugqinsi, kuzoba i-palladium esiliva (AgPd), i-pllladium yegolide (AuPd); Ku-DCB (I-Direct Copper Bonded) kuzoba ithusi kuphela

- Izinga lokushisa lokufaka isicelo: -55~850C

- Inani le-thermal conductivity: 24W~28W/mK (Al2O3); 150W~240W/mK ye-ALN , 220~250W/mK ye-BeO;

- Amandla okucindezela aphezulu: >7,000 N/cm2

- I-Voltage Yokuhlukana (KV/mm): 15/20/28 ku-0.25mm/0.63mm/1.0mm ngokulandelanayo

- I-Thermal Expansion Conefficient(ppm/K): 7.4 (ngaphansi kuka-50~200C)

Izinhlobo zama-PCB e-ceramic

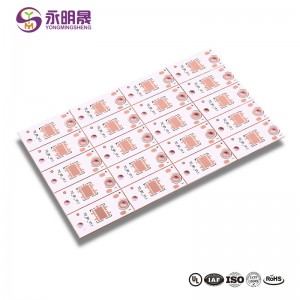

1. Ukushisa okuphezulu kwe-ceramic PCB

2. Ukushisa okuphansi kwe-ceramic PCB

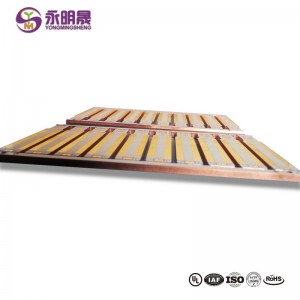

3.Thick ifilimu Ceramic PCB

Amakhono okukhiqiza we-YMS Ceramic PCB:

| Uhlolojikelele lwamakhono okukhiqiza we-YMS Ceramic PCB | ||

| Isici | amakhono | |

| Isendlalelo | 1-2L | |

| Impahla Nokuqina | I-Al203: 0.15, 0.38,0.5,0.635,1.0,1.5,2.0mm njll. | |

| ISONO: 0.25,0.38,0.5,1.0mm njll. | ||

| I-AIN: 0.15, 0.25,0.38,0.5, 1.0mm njll. | ||

| I-Thermal conductivity | Al203: Min. 24 W/mk kufika ku-30W/mk | |

| ISONO: Min. 85 W/mk kufika ku-100W/mk | ||

| AIN: Min. 150 W/mk kufika ku-320 W/mk | ||

| I-Al2O3 | I-Al2O3 inokukhanya okungcono kakhulu - okuyenza ifanele imikhiqizo ye-LED. | |

| ISONO | I-SiN ine-CTE ephansi kakhulu. Ihlanganiswe namandla e-Rapture High ingamelana nokushaqeka okunamandla okushisayo. | |

| I-AlN | I-AlN ine-Superior Thermal Conductivity - iyenza ifaneleke izinhlelo zokusebenza zamandla aphezulu kakhulu ezidinga indawo engaphansi eshisayo engcono kakhulu. | |

| Ubukhulu beBhodi | 0.25mm-3.0mm | |

| ukujiya kwethusi | 0.5-10OZ | |

| Ubuncane bomugqa nobubanzi | 0.075mm/0.075mm(3mil/3mil) | |

| Okukhethekile | I-Countersink, i-Counterbore drilling.etc. | |

| Min mechanical Usayizi yamba | 0.15mm (6mil) | |

| Izinto zama-conductor: | Ngobuchwepheshe befilimu ezacile, ewugqinsi, kuzoba i-palladium esiliva (AgPd), igolide pllladium (AuPd), iPlatinum For DCB (Direct Copper Bonded) kuzoba ithusi kuphela. | |

| I-Surface Qeda | I-HASL, iholele mahhala i-HASL, i-ENIG, ukucwiliswa kweTin, i-OSP, ukucwiliswa kwesiliva, umunwe wegolide, i-Electroplating Hard Gold, i-OSP ekhethiwe, ENEPIG.etc | |

| Isifihla Solder | Okuluhlaza okotshani, obomvu, ophuzi, ohlaza okwesibhakabhaka, omhlophe, omnyama, onsomi, uMatte Mnyama, uMatte oluhlaza. | |

| ephucuziwe | Ra <0.1 um | |

| lapped | Ra <0.4 um | |

Funda kabanzi ngemikhiqizo ye-YMS

Funda izindaba ezengeziwe