Inkqubo yokwenziwa kweAluminiyam yePCB

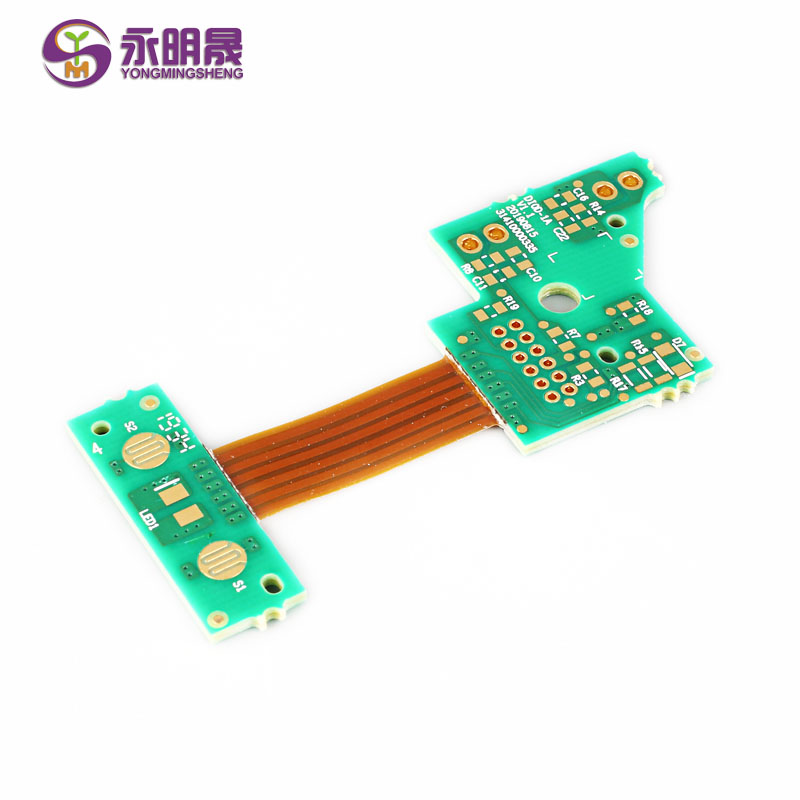

Inkqubo yokwenziwa kweAluminiyam yePCBInkqubo yokwenziwa kwe- aluminium PCB ene-OSP umphezulu ogqityiweyo: Ukusika→Ukwemba→Isetyhula→ukuchongwa kweAcid/alkaline→Imaski yeSolder→Iscreen sesilika→V-cut→Uvavanyo lwePCB→OSP→FQC→FQA→Ukupakishwa→Ukuhanjiswa.

Inkqubo yokwenziwa kwe-aluminiyam PCB enomphezulu we-HASL ukugqiba: Ukusika→Ukwemba→Isetyhula→I-Acid/alkaline etching→Imaski yeSolder→Iscreen sesilika→HASL→V-cut→Uvavanyo lwePCB→FQC→FQA→Ukupakishwa→Ukuhanjiswa.

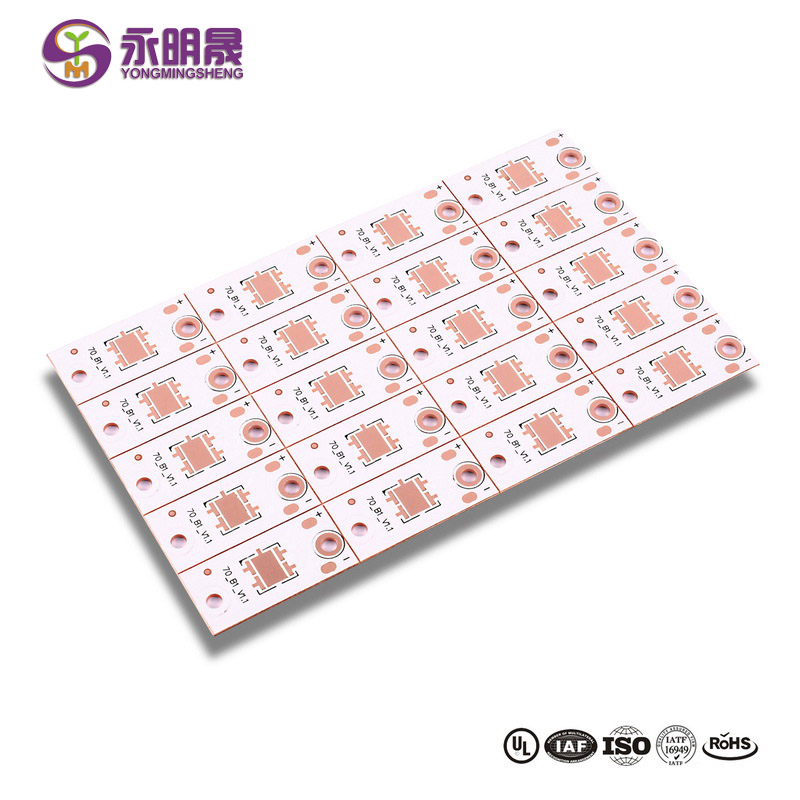

I-YMSPCB inokubonelela nge-PCB engundoqo ye-aluminium kunye nenkqubo yokugqiba umphezulu ofanayo njenge-FR-4 PCB: Ukuntywiliselwa kweGolide / encinci / isilivere, i-OSP, njl.

Kwinkqubo yokuvelisa i-PCB ye-aluminium, umgca obhityileyo we-dielectric wongezwa phakathi koluhlu lwesekethe kunye nomgangatho wesiseko. Lo maleko we-dielectric zombini i-insulating yombane, kunye ne-thermal conductive. Emva kokongeza i-dielectric layer, i-circuit layer okanye i-foil yobhedu ifakwe

Qaphela

1. Beka iibhodi kwi-cage-shelf okanye uzihlukanise ngephepha okanye iiplastiki zeplastiki ukuze ugweme imikrwelo ngexesha lokuthuthwa kwemveliso yonke.

2. Ukusebenzisa imela ukukrwela umaleko we-insulated kuyo nayiphi na inkqubo akuvumelekanga ngexesha lemveliso yonke.

3. Kwiibhodi ezishiyiweyo, izinto ezisisiseko azikwazi ukuqhutyelwa kodwa ziphawulwe kuphela "X" nge-oil-pen.

4. Ukuhlolwa okupheleleyo kwepateni kunyanzelekile kuba akukho ndlela yokusombulula ingxaki yepateni emva kokukrolwa.

5. Ukuqhuba iitshekhi ze-100% ze-IQC kuzo zonke iibhodi zokukhangela ngaphandle ngokwemigangatho yenkampani yethu.

6. Qokelela zonke iibhodi ezineziphene kunye (ezifana nombala omfiliba kunye nemikrwelo yomphezulu we-AI) ukuba ziphinde zisetyenzwe.

7. Nayiphi na ingxaki ngexesha lemveliso kufuneka ixelelwe kubasebenzi bezobugcisa abanxulumeneyo kwangethuba ukuze isonjululwe.

8. Zonke iinkqubo maziqhutywe ngokungqongqo ngokulandela iimfuno.

Iibhodi zesekethe eziprintiweyo zeAluminiyam zikwabizwa ngokuba ziiPCB zesiseko sesinyithi kwaye ziqulathe iilaminates ezisekelwe kwisinyithi ezigqunywe ngamaleko esekethe yobhedu. Zenziwe ngamacwecwe e-alloy adibanisa i-aluminium, i-magnesium kunye ne-silumin (Al-Mg-Si). IiPCB zeAluminiyam zihambisa umbane ogqwesileyo, amandla obushushu obulungileyo kunye nokusebenza komatshini ophezulu, kwaye ziyahluka kwezinye iiPCB ngeendlela ezininzi ezibalulekileyo.

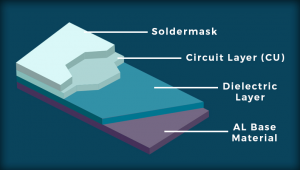

Iileya zePCB zeAluminiyam

ULENKO LWESISEKO

Olu luhlu luqukethe i-aluminium alloy substrate. Ukusetyenziswa kwealuminiyam kwenza olu hlobo lwePCB lube lolona khetho lubalaseleyo kwitekhnoloji yomngxuma, kuxoxwe ngayo kamva.

I-THERMAL INSUULATION LAER

Lo maleko yinxalenye ebalulekileyo yePCB. Iqulethe i-polymer ye-ceramic eneempawu ezibalaseleyo ze-viscoelastic, ukuxhathisa okukhulu kwe-thermal kwaye ikhusela i-PCB kuxinzelelo lomatshini kunye nobushushu.

ULENKO LWESEKHITHI

Uluhlu lwesiphaluka luqulethe i-foil yobhedu ekhankanywe ngaphambili. Ngokubanzi, abavelisi bePCB basebenzisa iifoyile zobhedu ukusuka kwenye ukuya kwi-ounces ezili-10.

ULEYA DIELECTRIC

Umaleko we-dielectric we-insulation ufunxa ubushushu njengoko umbane uhamba kwiisekethe. Oku kudluliselwa kwi-aluminium layer, apho ubushushu buchithwa khona.

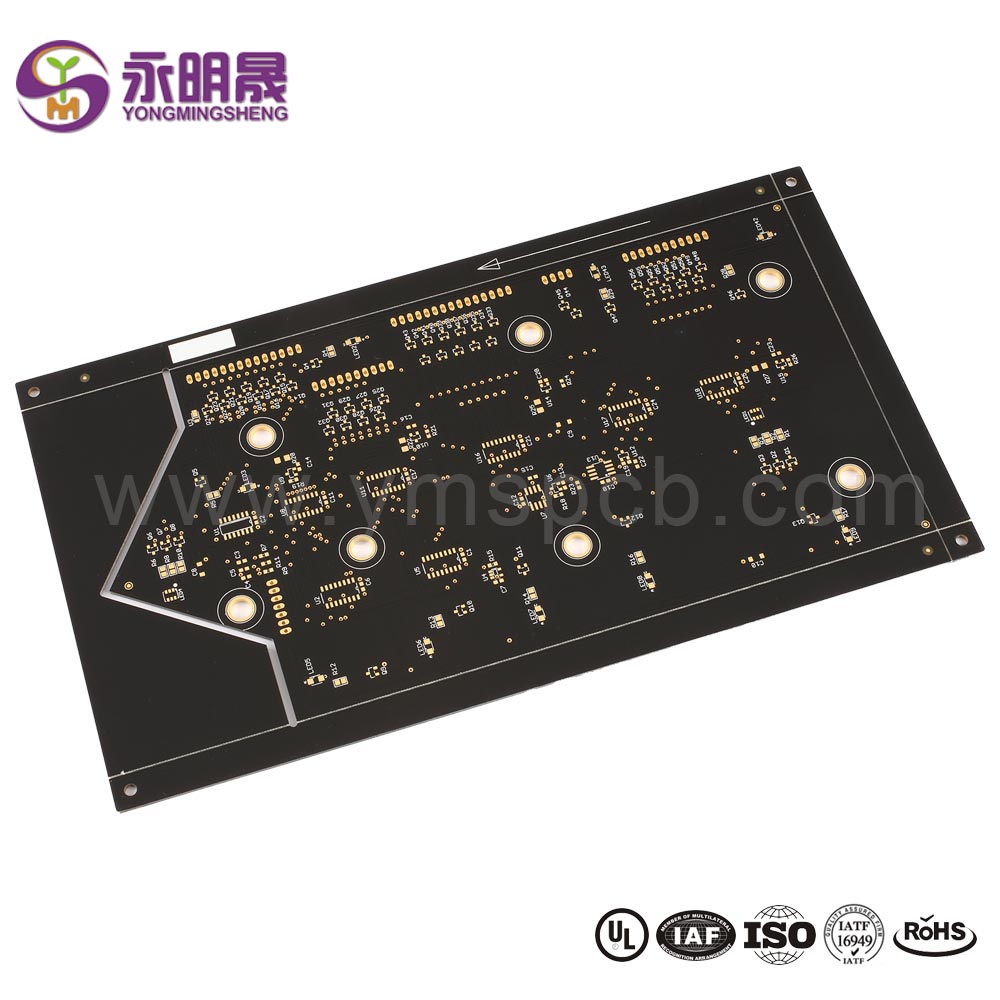

Ukufikelela esona siphumo siphezulu sokukhanya okunokwenzeka kubangela ukwanda kobushushu. IiPCBs ezinobuxhakaxhaka bobushushu obuphuculweyo zandisa ubomi bemveliso yakho egqityiweyo. Umenzi ofanelekileyo uya kukunika ukhuseleko oluphezulu, ukunciphisa ubushushu kunye nokuthembeka kwenxalenye. Kwi-YMS PCB, sizibambele kwimigangatho ephezulu kunye nomgangatho ofunwa ziiprojekthi zakho.

Funda ngakumbi malunga neemveliso zeYMS

Ixesha lokuposa: Jan-20-2022