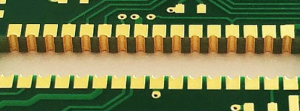

Okwangoku, kukho iindidi ezimbini PCB webhodi edge uyilo: metallization kunye non-metallization. Ukungabikho kwe-metallization, abavelisi kwishishini baye bavuthwa, kodwa iteknoloji ye-metallization isengakabikho. Kule mihla, iimfuno ezininzi zemveliso zabathengi ziguqukela kwi- PCB yentsimbi ye-edging . Ngoko ke, umgangatho PCB metal edging iye yaba ingqalelo abathengi 'kunye nabavelisi kuba umgangatho wayo ngqo kuchaphazela ukusetyenziswa kweemveliso.

Zeziphi izicelo zokufakwa komphetho kwiPCB?

Iibhodi zesekethe zomphetho zixhaphakile kumashishini amaninzi, kwaye i-edge plating yinto eqhelekileyo. Uya kufumana i-PCB edge castellation (okanye i-edge plating PCBs) isetyenziswe kwiimeko ezininzi, kubandakanya:

· Ukuphucula amandla okuphatha ngoku

· Uqhagamshelo lomphetho kunye nokhuseleko

· I-Edge soldering ukuphucula ukwenziwa

· Inkxaso engcono yoqhagamshelo olufana neebhodi ezityibilika kwiikhongo zentsimbi

Yintoni inkqubo yePCB edge plating?

Njengoko usazi, kukho imiceli mngeni enkulu kumvelisi wePCB eninzi kakhulu kwindlela yokulungisa imiphetho ecandiweyo kunye nokuncamatheliswa kobude bobomi bezinto ezicandiweyo, ngaphezu koko, ifuna ukuphathwa okuchanekileyo kwimveliso yePCB esetyenziselwa umda. PCB isolder. Singaqiniseka ukuba PCB edge castellation ngokucokisekileyo ilungiselela imiphetho imiphezulu, osebenzisa ubhedu olucandiweyo ukuze adhesion ngokukhawuleza kwaye iinkqubo ibhodi yesekethe ukuqinisekisa ukuba adhesion ixesha elide phakathi umaleko ngamnye.

Ngokungathandabuzekiyo, sinokuyilawula ingozi enokuthi ifakwe kumngxunya kunye ne-edge plating ngenkqubo elawulwayo ngexesha lokwenziwa kwebhodi yesekethe eprintiweyo kwi-edge soldering. Ke eyona nkxalabo ibalulekileyo kukwenziwa kwee-burrs, ezikhokelela ekungaqhubekiyo ekufakweni kwiindonga zomngxunya kunye nokunciphisa ubomi bokunamathela kwi-edge plating.

Iicontours zangaphandle, ukuba zenziwe ngesinyithi, kufuneka zigaywe phambi kwenkqubo yokufakwa komngxuma, njengoko ukufakwa kwesinyithi kwimida kwenzeka ngeli nyathelo lokwenziwa. Emva kokubekwa kobhedu, ukugqitywa kwendawo ekujoliswe kuyo ekugqibeleni kusetyenziswe emaphethelweni.

Imiba yoKwakha:

1. I-Copper Peeling -Ukufaka phezu kwendawo enkulu ye-substrate kunokukhokelela kwi-peeling yethusi edibeneyo ngenxa yokungabikho kwamandla okubambelela. Silungisa oku ngokuqala ngokurhaxa umphezulu ngokudibanisa imichiza kunye nezinye iindlela zobunini. Okulandelayo, siqeshe i-metalization ethe ngqo, enamandla amakhulu ebhondi yobhedu, ukulungiselela umphezulu wokwaleka.

2. IiBurrs -Amaxesha amaninzi i-edge plating, ngakumbi kwimingxuma ye-castellation, inokubangela ii-burrs ezivela kwinkqubo yokugqibela yomatshini. Sisebenzisa inkqubo elungisiweyo, ukuhamba kwenkqubo yobunikazi ekhokelela ekubeni i-burrs igudiswe phantsi ekupheleni kwenqaku.

Inqaku leFab:

1. Indawo ye-eriyali yepedi yegolide inkulu kakhulu, ichaphazela ukuthengiswa komthengi okanye ukuhanjiswa komqondiso.

2. I-pad edge yangaphakathi idibaniswe kwiingcingo ebhodini, okubangela isiphaluka esifutshane.

3. Umngxuma wesitampu uyilwe kwi-edging groove kwaye kufuneka uphathwe kwinkqubo ye-2 yokugaya.

4. Ngokwenziwa kwenkqubo enxulumene nenkqubo yee-PCBs zodwa njengephaneli, i-metalization eqhubekayo yemiphetho yangaphandle ayinakwenzeka. Akukho metallization ingasetyenziswa apho iibhulorho zepaneli ezincinci zikhoyo.

5. Isicelo esinye, i-metallization yesilayidi inokugqunywa ngemaski ye-solder.

Xa uthenga iibhodi zokucwenga ezisemacaleni, kufuneka uqinisekise kunye nomthengisi wakho we-PCB ukuba kunokwenzeka ukwenza ii-PCBs kunye nenkqubo yokucwenga, kunye nobungakanani apho umenzi weplate anokuphelisa i-PCB. Iifayile zakho zeGerber okanye umzobo welaphu kufuneka ubonise kumaleko oomatshini apho zidinga ukubekwa kwesilayidi, kunye nokugqiba komphezulu abawufunayo kuwo. Uninzi lwabavelisi bakhetha i-ENIG ekhethiweyo njengokuphela komphezulu ogqibeleleyo olungele i-castellation engqukuva.

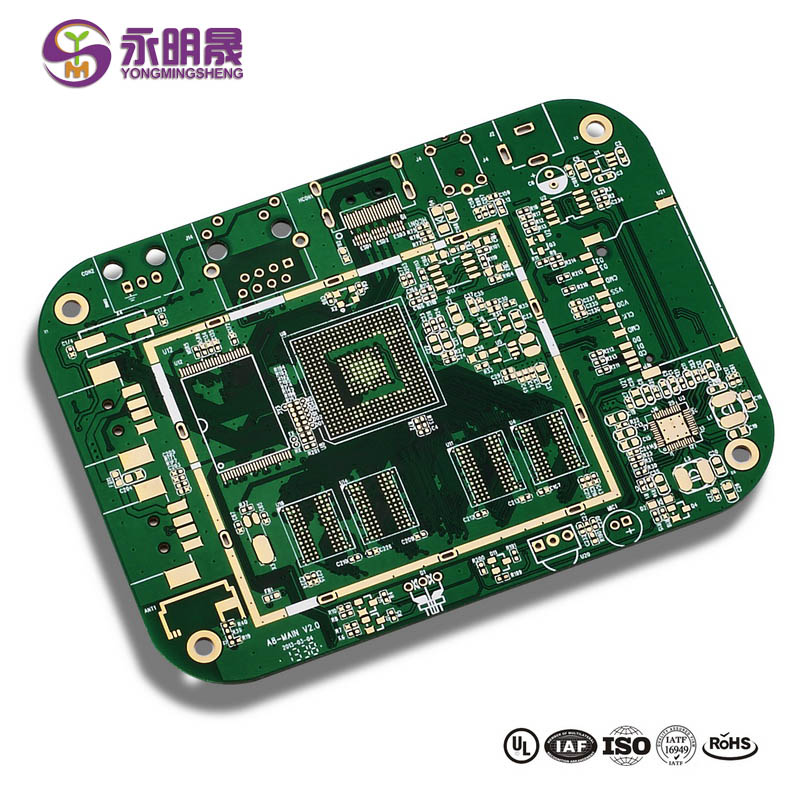

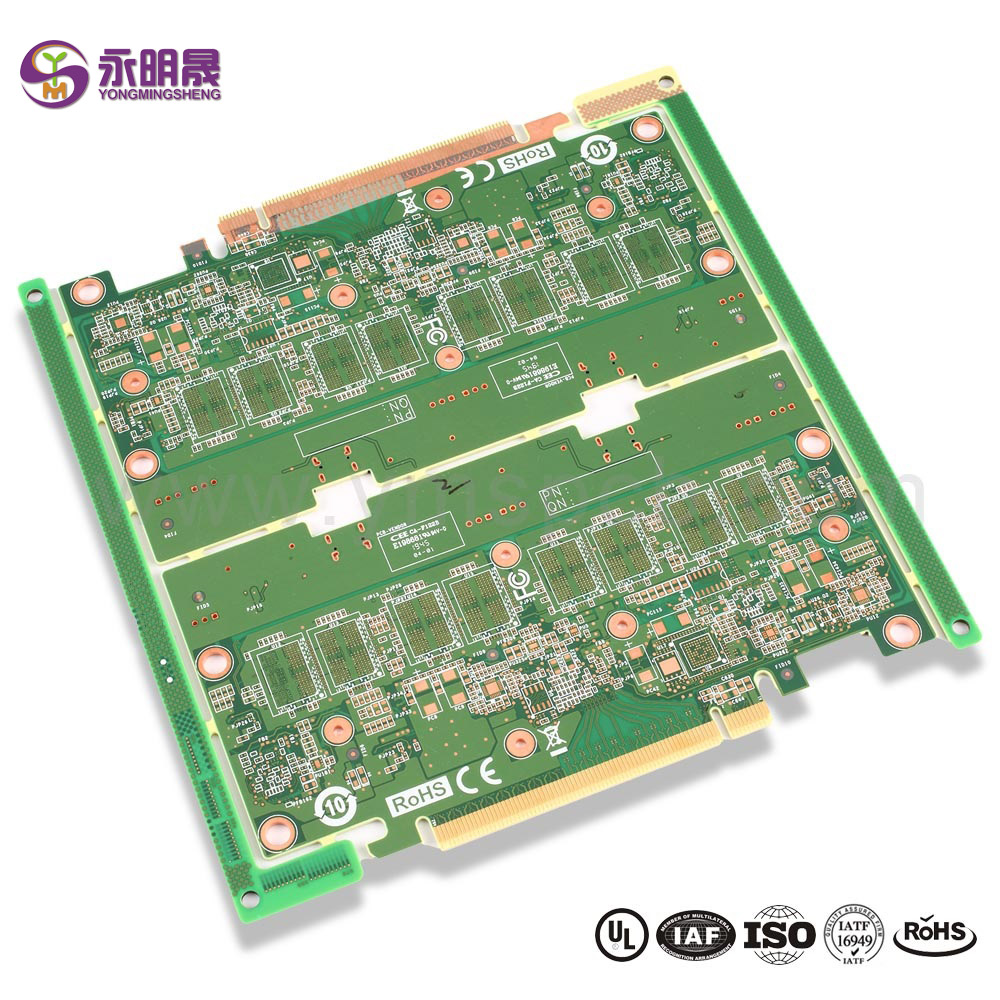

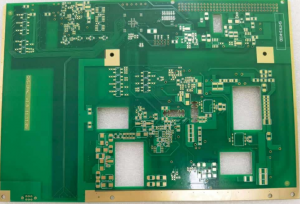

I-YMS Electronics Co., Ltd. ngumvelisi ochwephesha weebhodi zesekethe ezichanekileyo ezichanekileyo, imodyuli yokuntywiliselwa iibhodi zesekethe yegolide, iibhodi zesekethe zemoto, iirekhodi zokuqhuba, izixhobo zombane zeCOB, iibhodi zekhompyuter, iibhodi zesekethe zonyango, iibhodi zemodyuli zokudibanisa, ukunyanzeliswa komngxuma oyimfama. ibhodi, i-thermoelectric yokwahlula i-copper substrate, njl. I-RayMing ibonelela ngesiqinisekiso somgangatho ophezulu kunye nokuhanjiswa kwexesha, ishishini lobuchwepheshe obuphezulu kunye neentengiso zizonke. Ukuba kukho imfuno yeebhodi zegolide ezicatyiswe ngecala, nceda ukhululeke ukudibana nathi!

Funda ngakumbi malunga neemveliso zeYMS

Ixesha lokuposa: Apr-07-2022