IiPCB zeCeramic zenziwe nge-substrate ye-ceramic, umaleko wokudibanisa, kunye nomgangatho wesekethe. Ngokungafaniyo ne-MCPCB, ii- PCB ze-ceramic azinayo i-insulation layer, kwaye ukuvelisa umaleko wesekethe kwi-substrate ye-ceramic kunzima. Zenziwa njani iiPCB zeceramic? Ukusukela oko imathiriyeli yeceramic yayisetyenziswa njenge-PCB substrates, iindlela ezimbalwa zaphuhliswa ukwenza umaleko wesekethe kwi-substrate ye-ceramic. Ezi ndlela zi-HTCC, i-DBC, ifilimu eshinyeneyo, i-LTCC, ifilimu encinci, kunye ne-DPC.

I-HTCC

Iinzuzo: amandla aphezulu okwakhiwa; high conductivity thermal; uzinzo oluhle lweekhemikhali; ukuxinana kweengcingo eziphezulu; Isiqinisekiso seRoHS

I-Cons: ukungahambi kakuhle kweesekethe; amaqondo aphezulu e-sintering; iindleko ezibizayo

I-HTCC sisishunqulelo sobushushu obuphezulu be-co-fired ceramic. Yeyona ndlela yokuqala yokwenza i-ceramic PCB. Izixhobo ze-ceramic ze-HTCC yi-alumina, i-mullite, okanye i-aluminiyam nitride.

Inkqubo yokwenziwa kwayo yile:

Kwi-1300-1600℃, umgubo we-ceramic (ngaphandle kweglasi eyongeziweyo) iyagalelwa kwaye yomiswe ukuze iqine. Ukuba uyilo lufuna ngemingxuma, imingxuma igrunjwa kwi-substrate board.

Ngexesha elifanayo lobushushu obuphezulu, isinyithi esinyibilikisiweyo sincibilika njengentsimbi yentsimbi. Isinyithi sinokuba yi-tungsten, i-molybdenum, i-molybdenum, i-manganese, njalo njalo. Isinyithi sinokuba yi-tungsten, i-molybdenum, i-molybdenum, kunye ne-manganese. I-metal paste iprintwa ngokoyilo ukwenza umaleko wesekethe kwi-substrate yesekethe.

Okulandelayo, i-4% -8% i-sintering aid yongezwa.

Ukuba iPCB inamaleko amaninzi, iileya zilaminethiwe.

Emva koko kwi-1500-1600 ℃, yonke indibaniselwano ifakwe kwi-sintered ukwenza iibhodi zesekethe yeceramic.

Ekugqibeleni, imaski ye-solder yongezwa ukukhusela umaleko wesiphaluka.

IFilimu encinci yeCeramic PCB Manufacturing

Iinzuzo: ukushisa okuphantsi kokuvelisa; isiphaluka esihle; umgangatho omhle womphezulu

Ububi: izixhobo zokuvelisa ezibizayo; ayinakwenza iisekethe ezine-dimensional ezintathu

Umaleko wobhedu kwifilimu ecekethekileyo ye-ceramic PCBs inobunzima obungaphantsi kwe-1mm. Izinto eziphambili ze-ceramic ze-PCBs ze-ceramic ezicekethekileyo ziyi-alumina kunye ne-aluminiyam nitride. Inkqubo yokwenziwa kwayo yile:

I-substrate ye-ceramic icocwa kuqala.

Kwiimeko ze-vacuum, ukufuma kwi-substrate ye-ceramic ku-evaporated nge-thermal.

Emva koko, umaleko wobhedu wenziwa kumphezulu we-ceramic substrate nge-magnetron sputtering.

Umfanekiso wesekethe wenziwa kumaleko obhedu ngeteknoloji ye-photoresist ephuzi.

Emva koko ubhedu olugqithisileyo lususwa ngokucofa.

Ekugqibeleni, imaski ye-solder yongezwa ukukhusela isiphaluka.

Isishwankathelo: ifilimu ebhityileyo yokwenziwa kwe-ceramic PCB igqityiwe ikwimeko yokufunxa. Itekhnoloji ye-yellow light lithography ivumela ukuchaneka ngakumbi kwisekethe. Nangona kunjalo, ukuveliswa kweefilimu ezincinci kunomda wobunzima bobhedu. IiPCB ze-ceramic ze-ceramic ezicekethekileyo zilungele ukupakishwa okuchanekileyo okuphezulu kunye nezixhobo ezinobungakanani obuncinci.

I-DPC

Iinzuzo: akukho mda kuhlobo lwe-ceramic kunye nobukhulu; isiphaluka esihle; ubushushu obuphantsi bokuvelisa; umgangatho omhle womphezulu

Ububi: izixhobo zokuvelisa ezibizayo

I-DPC sisishunqulelo sobhedu oluthe nkqo. Iphuhla kwindlela yokuvelisa ifilimu ye-ceramic kwaye iphucula ngokudibanisa ubukhulu bobhedu ngokutyalwa. Inkqubo yokwenziwa kwayo yile:

Inkqubo efanayo yokuvelisa ifilimu encinci de kube umfanekiso wesiphaluka uprintwe kwifilimu yobhedu.

Ubunzima bobhedu besiphaluka bongezwa nge-plating.

Ifilimu yobhedu iyasuswa.

Ekugqibeleni, imaski ye-solder yongezwa ukukhusela isiphaluka.

Ukuqukumbela

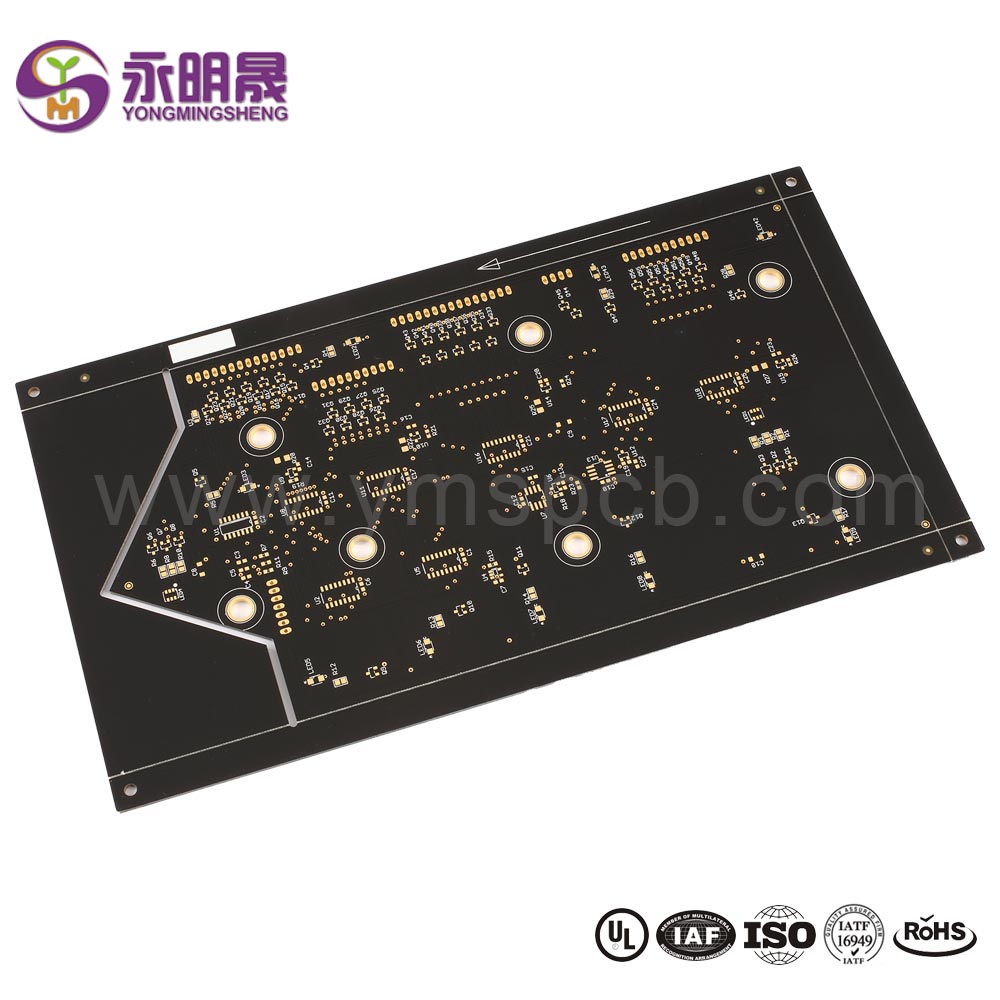

Eli nqaku lidwelisa iindlela zokwenziwa kwe-ceramic PCB eziqhelekileyo. Yazisa iinkqubo zokwenziwa kwe-ceramic PCB kwaye inika uhlalutyo olufutshane lweendlela. Ukuba iinjineli/iinkampani zezisombululo/amaziko afuna ukuba nee-PCB zeceramic zenziwe kwaye zidityaniswe, i-YMSPCB iya kuzisa i-100% yeziphumo ezanelisayo kubo.

Ividiyo

Funda ngakumbi malunga neemveliso zeYMS

Ixesha lokuposa: Feb-18-2022