Flex rigid Board semi flex PCB Black Soldermask| YMSPCB

What is Semi-Flex PCB?

Yarim egiluvchan PCB ning eng an'anaviy ishlab chiqarish jarayoni bükme FR-4 materiallarini qabul qilish va an'anaviy qattiq tenglikni ishlab chiqarish jarayoniga ko'ra tenglikni ishlab chiqarish va keyinchalik chuqur frezeleme texnologiyasidan foydalanib, egilishi kerak bo'lgan joylarni ingichka qilish uchun yig'ilishning bükme aloqasi talablariga javob beradigan darajada ma'lum bir moslashuvchanlik darajasi.

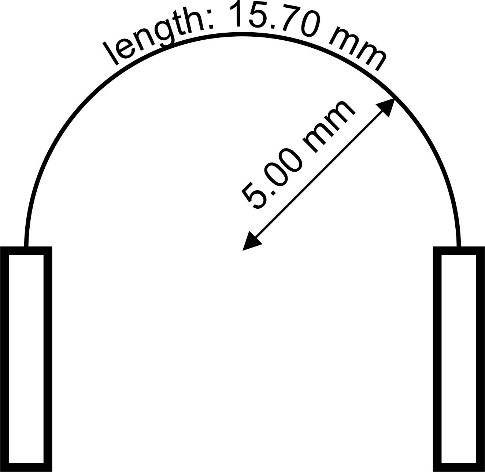

SEMI-FLEX uzunligi kalkulyatori: (2 x-x burilish radiusi) x (burilish burchagi / 360 °)

Masalan, radiusi 5 mm bo'lgan 180 graduslik burchak ostida 5 marta egilish uchun minimal egiluvchanlik 15,7 mm bo'lgan uzunlik talab qilinadi

YMS Semi-Flex PCB ishlab chiqarish kapa :

| YMS Semi-Flex PCB ishlab chiqarish imkoniyatlariga umumiy nuqtai | ||

| Xususiyat | imkoniyatlar | |

| Qatlamlarni hisoblash | Moslashuvchan qismda 1 - 2 o'tkazgich qatlami bo'lgan 2-20L , | |

| Qattiq-Flex qalinligi | 0,5 mm-5,0 mm | |

| Moslashuvchan qismdagi tenglikni qalinligi | 0,15-0,8 mm ± 0,05 mm | |

| mis Qalinligi | 1/4OZ-10OZ | |

| Minimal chiziq kengligi va bo'sh joy | 0,05 mm / 0,05 mm (2 mil / 2 mil) | |

| Qattiqlashtiruvchilar | Zanglamaydigan po'lat, PI, FR4, alyuminiy va boshqalar. | |

| Materiallar | FR4, RA mis, HTE mis, yopishtiruvchi, Bondply , qoplama, egiluvchan lehim maskasi | |

| Eng kam mexanik burg'ulash hajmi | 0,15 mm (6 mil) | |

| Minimal lazer teshiklari hajmi: | 0,075 mm (3 milya) | |

| Yuzaki tugatish | Mikroto'lqinli / chastotali PCB-ning sirtini qoplash uchun mos keladigan materiallar: Elektrsiz nikel, Immersion Gold, ENEPIG, qo'rg'oshinsiz HASL, Immersion Silver.etc. | |

| Lehim maskasi | Yashil, qizil, sariq, moviy, oq, qora, binafsha, mat qora, mat yashil va boshqalar. | |

| Covrelay (Flex qismi) | Sariq qoplama, WhiteCoverlay, qora qoplama |

|

YMS mahsulotlari haqida ko'proq bilib oling

Ko'proq yangiliklarni o'qing

What is a rigid flex board?

The rigid-flex board is a flexible circuit board(FPC) and a rigid circuit board (PCB), which are combined together according to the relevant process requirements through pressing and other processes in the PCB proofing to form a circuit board with FPC characteristics and PCB characteristics.

What is difference between rigid and flexible boards?

As the names suggest, a rigid PCB is a circuit board built on a rigid base layer that cannot bend, while a flexible PCB, also called a flex circuit, is built on a flexible base capable of bending, twisting and folding.

Where are rigid flex PCBs used?

You’ll find them in commercial, industrial and military applications. From digital cameras to cell phones to smart devices, they serve them all. Especially in the medical industry for developing pacemakers for their weight reduction, space, and flexible capabilities.