Habeli mahlakoreng a mabeli PCB maemo a pcb Countersink baetsi | YMSPCB

Hatisitsoeng oa Potoloho Board Selelekela

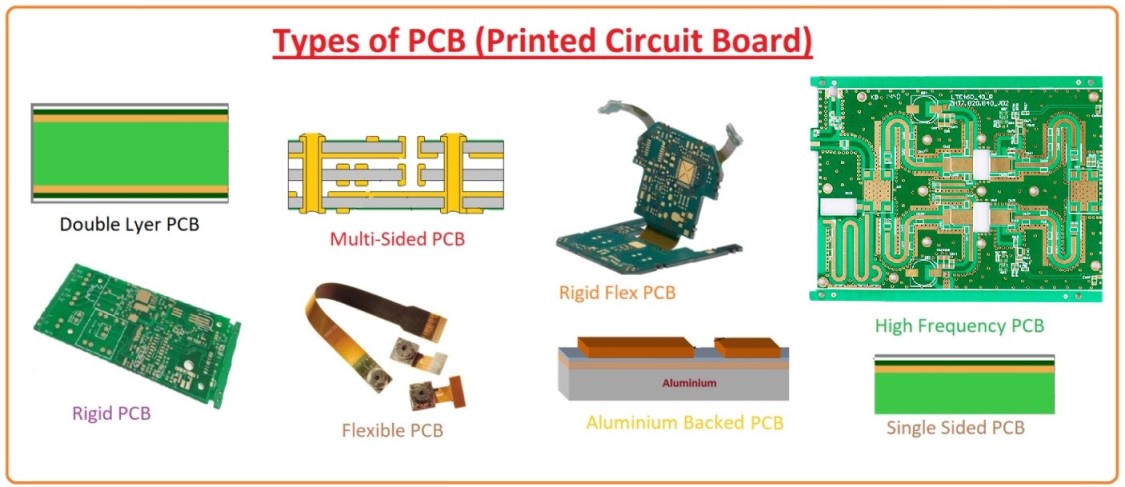

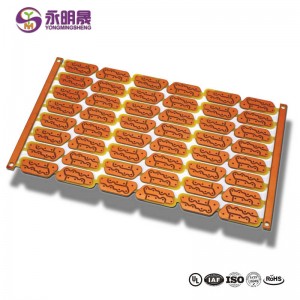

A Boto ea potoloho e mechanically supports and electrically connects electrical or electronic components using conductive tracks, pads and other features etched from one or more sheet layers of copper laminated onto and/or between sheet layers of a non-conductive substrate. Components are generally soldered onto the PCB to both electrically connect and mechanically fasten them to it.PCBs can be single-sided (one copper layer), double-sided (two copper layers on both sides of one substrate layer), or multi-layer (outer and inner layers of copper, alternating with layers of substrate). Multi-layer PCBs allow for much higher component density, because circuit traces on the inner layers would otherwise take up surface space between components. The rise in popularity of multilayer PCBs with more than two, and especially with more than four, copper planes was concurrent with the adoption of surface mount technology.

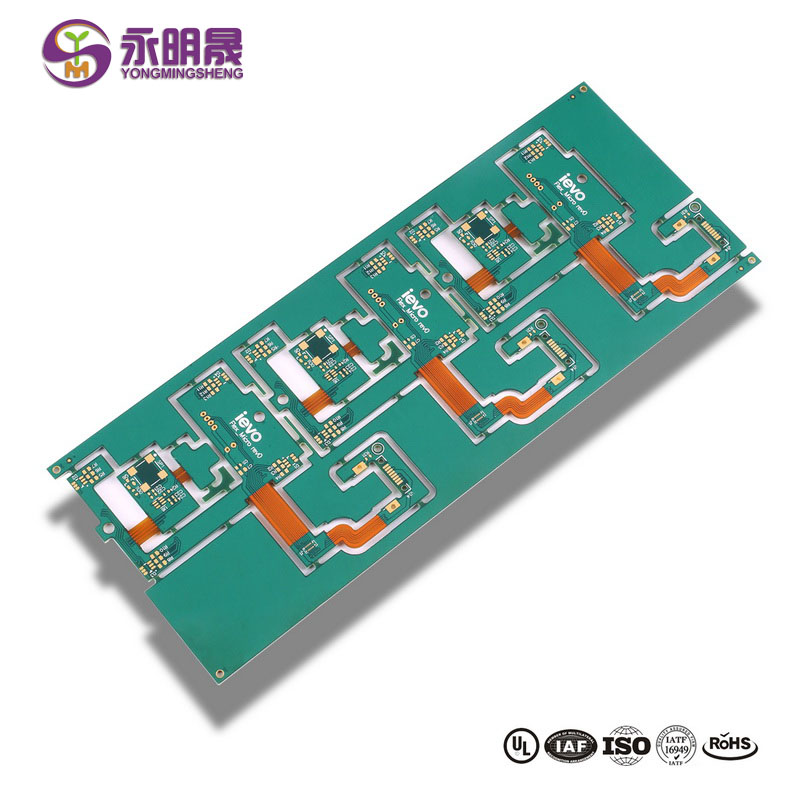

Liboto tsa potoloho tse mahlakore a mabeli li rarahane ho feta PCB e nang le lehlakore le le leng. Liboto tsena li na le karolo e le 'ngoe feela ea substrate ea motheo. Leha ho le joalo, li na le lihlopha tsa conductive ka lehlakoreng le leng. Ba sebelisa koporo e le thepa conductive. Ha re ikakhele ka setotsoana ka har'a PCB e mahlakoreng a mabeli ho ithuta haholoanyane!

Sebopeho le Lisebelisoa tsa PCB e Mahlakore Habeli

Lisebelisoa tsa PCB tse mahlakoreng a mabeli li ka fapana ho latela mofuta oa morero. Leha ho le joalo, thepa ea mantlha e batla e tšoana le liboto tsohle tsa potoloho. Leha ho le joalo, sebopeho sa PCB se fapana ho ea ka mofuta ho ea ho mofuta.

Substrate: Ke thepa ea bohlokoa ka ho fetisisa e entsoeng ka fiberglass. U ka e nka e le skeleton ea PCB.

Lera la Koporo: E ka ba foil kapa seaparo se feletseng sa koporo. Ke kahoo e itšetlehileng ka mofuta oa boto. Sephetho se tšoana le hore na u sebelisa foil kapa seaparo sa koporo. Liboto tsa potoloho tse mahlakoreng a mabeli li na le lera la koporo le tsamaisang mahlakore ka bobeli.

Solder Mask: Ke lera le sireletsang la polymer. Kahoo, e thibela koporo hore e se ke ea e-ba khutšoanyane. U ka e nka e le letlalo la boto ea potoloho. Double sided PCB soldering ke mohato oa bohlokoa haholo bakeng sa ho tšoarella.

Silkscreen: ke karolo ea ho qetela ea silika. Le hoja e se na karolo leha e le efe mosebetsing oa boto ea potoloho. Baetsi ba e sebelisa ho bontša likarolo tsa linomoro. Linomoro tsa likarolo li bohlokoa haholo molemong oa tlhahlobo. Ntle le moo, o ka hatisa li-logos tsa k'hamphani ea hau kapa lintlha tse ling ka mokhoa oa mongolo.

Melemo le Mefokolo ea Maboto a Potoloho a Mahlakore Habeli

Mona ke tse ling tse ntle le tse mpe tsa liboto tsa potoloho tse hatisitsoeng ka mahlakoreng a mabeli:

Melemo ea Maboto a Potoloho a Mahlakore Habeli

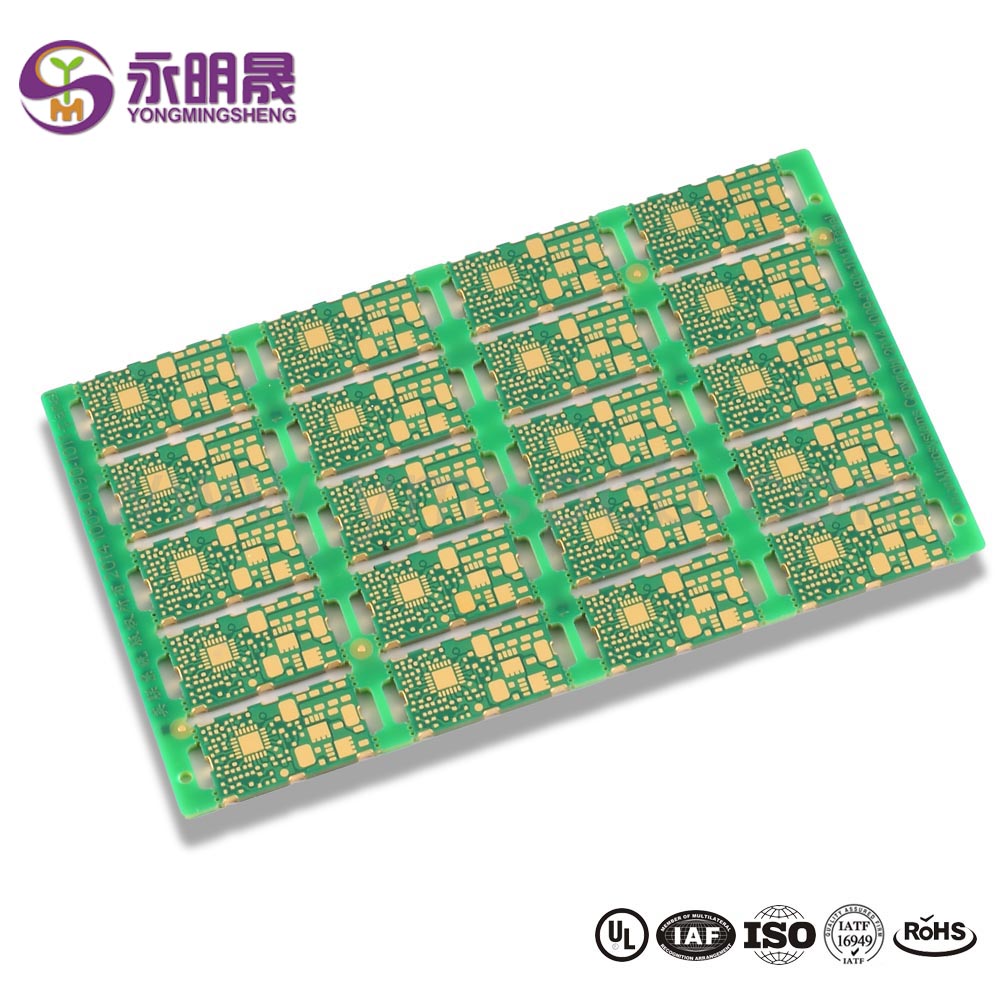

Boleng bo Phahameng: Ho rala le ho rala PCB ena ho hloka mosebetsi o mongata. Ho hlahisa liboto tsa potoloho tsa boleng bo holimo.

Sebaka se Lekane bakeng sa Likaroloana: E boloka sebaka se eketsehileng bakeng sa likarolo. Hobane mahlakore ka bobeli a lera ke conductive.

Likhetho tse ling tsa Moqapi: E na le likarolo tsa conductive mahlakoreng ka bobeli. O ka hokela likarolo tse fapaneng tsa elektronike mahlakoreng ka bobeli. Kahoo o na le likhetho tse ngata tsa moralo.

Sourcing and Sinking Current: Ha u ntse u e sebelisa e le mokato o ka tlase, u ka e sebelisa bakeng sa ho teba le ho fumana hona joale.

Tšebeliso: Ka lebaka la katleho ea eona, u ka e sebelisa lits'ebetsong tse ngata.

Melemo ea liboto tsa potoloho tse nang le mahlakore a mabeli

Litšenyehelo tse Phahameng: Ho etsa hore mahlakore ka bobeli a sebetse, ho tla ka litšenyehelo tse phahameng hanyane.

Ho Hlokahala Moqapi ea Tsebo: Ho na le ts'ebetso e thata ea ho etsa PCB e mahlakoreng a mabeli bakeng sa sebopeho sa eona. Ka hona, o hloka lienjineri tse hloahloa bakeng sa lihlahisoa tsa eona.

Nako ea Tlhahiso: Nako ea tlhahiso e feta PCB e lehlakoreng le le leng ka lebaka la ho rarahana ha eona.

Kopo ea Maboto a Potoloho a Mahlakore Habeli

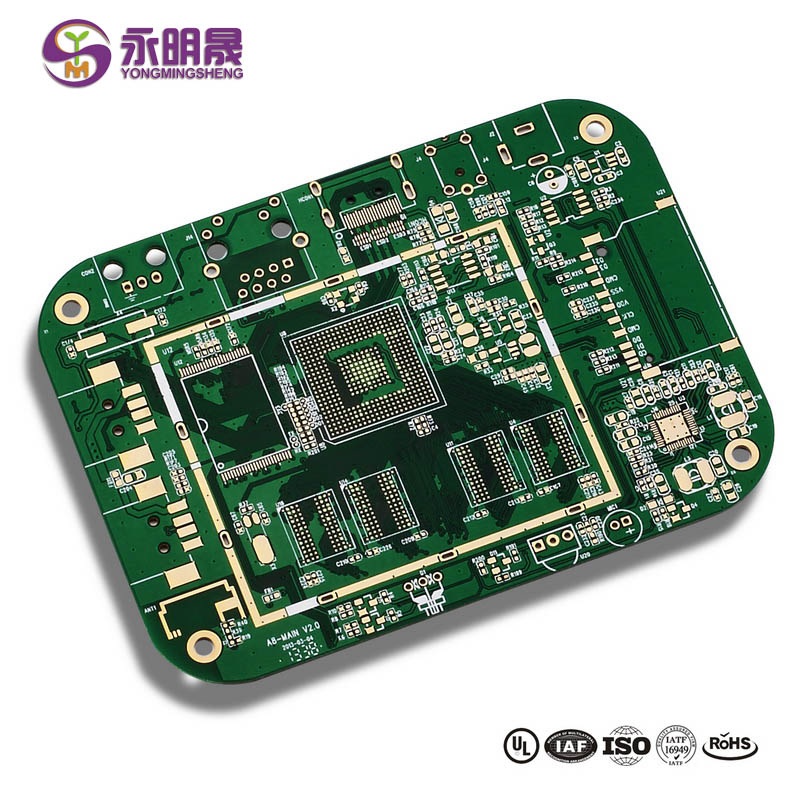

Mofuta ona oa boto ea potoloho o eketsa boima ba potoloho. Li tenyetseha haholoanyane hape. Hoo e ka bang baetsi bohle ba PCB ba mahlakoreng a mabeli ba e sebelisa ho lisebelisoa tse ngata tsa elektroniki. Ka tlase ke ts'ebeliso e makatsang ea liboto tsa potoloho tse mahlakore a mabeli:

HVAC le mabone a LED

Tsamaiso ea sephethephethe

Li-dashboards tsa likoloi

Laola li-relay le matla a ho sokoloha

Balaoli le lisebelisoa tsa motlakase

Ho etsa liteko le ho beha leihlo lisebelisoa tse fapaneng

Liprinta le litsamaiso tsa liselefouno

Mechini ea ho rekisa.

Bokgoni ba tlhahiso ea YMS e tloaelehileng ea PCB:

| YMS Normal PCB etsa thepa bokgoni kakaretso | ||

| Tšobotsi | bokhoni | |

| Palo ea Lera | 1-60L | |

| Fumaneha Normal PCB Technology | Ho pholletsa le lesoba le Palo ea Likarolo 16: 1 | |

| patoa ebile o foufetse ka | ||

| Motsoako | High maqhubu Material tse kang RO4350B le FR4 Remix jj | |

| Lebelo le phahameng joalo ka M7NE le FR4 Mix jj. | ||

| Boitsebiso | CEM- | CEM-1; CEM-2, CEM-4, CEM-5. joalo-joalo |

| FR4 | EM827, 370HR, S1000-2, IT180A, IT158, S1000 / S1155, R1566W, EM285, TU862HF, NP170G jj. | |

| Lebelo le phahameng | Megtron6, Megtron4, Megtron7, TU872SLK, FR408HR, N4000-13 Series, MW4000, MW2000, TU933 jj. | |

| phahameng maqhubu | Ro3003, Ro3006, Ro4350B, Ro4360G2, Ro4835, CLTE, Genclad, RF35, FastRise27 jj. | |

| Ba bang | Polyimide, Tk, LCP, BT, C-ply, Fradflex, Omega, ZBC2000, PEEK, PTFE, ceramic-based jj. | |

| Botenya | 0.3mm-8mm | |

| Botenya ba Max.copper | 10OZ | |

| Bophara ba mola le Bonyane | 0.05mm / 0.05mm (2mil / 2mil) | |

| BGA PITCH | 0.35 limilimithara | |

| Mets phethahetse Drilled Size | 0.15mm (6mil) | |

| Boemo ba tšobotsi bakeng sa lesoba | 16: 1 | |

| Holim qeta | HASL, E etella pele mahala HASL, ENIG, qoelisoa Tin, OSP, qoelisoa Silver, Gold monoana, Electroplating Hard Khauta, khetla OSP , ENEPIG.etc. | |

| Ka Khetho ea ho Tlatsa | Tsela e koahetsoe ebe e tlatsoa ka epoxy e tsamaisang kapa e sa tsamaeeng ebe e koaheloa le ho koaheloa (VIPPO) | |

| Koporo e tlatsitsoe, silevera e tletse | ||

| Ngoliso | ± 4mil | |

| Mask ea solder | Green, Red, Yellow, Blue, White, Black, Pherese, Matte Black, Matte tala.etc. | |

Video

Ithute haholoanyane ka lihlahisoa tsa YMS

Bala litaba tse ling

PCB e mahlakoreng a mabeli ke eng?

PCB e Mahlakore a Habeli kapa Boto ea Potoloho e hatisitsoeng ea Double Layer ha e rarahane ho feta li-PCB tsa Single Sided. Mefuta ena ea PCB e na le lera le le leng la substrate ea motheo empa lesela la conductive (koporo) mahlakoreng ka bobeli a substrate. Mask ea solder e sebelisoa mahlakoreng ka bobeli a boto.

PCB ea double layer e sebelisetsoa eng?

Electronics Consumer;Industrial Electronics;Lisebelisoa tsa Likoloi;Lisebelisoa tsa Bongaka

PCB e habeli e etsoa joang?

FR4+copper+soldermask+silkscreen

Phapano ke efe lipakeng tsa single layer le double layer PCB?

Setšoantšo sa PCB se nang le lehlakore le le leng se sebelisoang haholo-holo Network Printing(Screen Printing), ke hore, hanela holim'a koporo, Ka mor'a ho ts'oara, tšoaea khanyetso ea welding, ebe u qeta lesoba le sebōpeho sa karolo ka ho phunya.

Liboto tsa potoloho tse hatisitsoeng ka lehlakore le le leng li sebelisoa haholo mecheng e mengata ea elektronike, athe liboto tsa potoloho tse mahlakoreng a mabeli li atisa ho sebelisoa ho theknoloji e phahameng ea elektronike.

Liboto tsa potoloho tse hatisitsoeng ka lehlakore le le leng hangata li sebelisoa mefuteng ea lisebelisoa tsa elektroniki le lits'ebetso, ho kenyeletsoa lisebelisoa tsa lik'hamera, liprinta, lisebelisoa tsa seea-le-moea, li-calculator le tse ling tse ngata.