Ts'ebetso ea ea potoloho ea FPC board ke boto ea potoloho e ka tšeptjoang haholo ebile e tenyetseha e entsoeng ka polyimide kapa filimi ea polyester e le thepa ea motheo. E bitsoa boto e bonolo kapa FPC , e na le litšoaneleho tsa ho teteana ha lithapo tse phahameng, tse bobebe le botenya.

Kakaretso ea lihlahisoa tsa FPC flex board

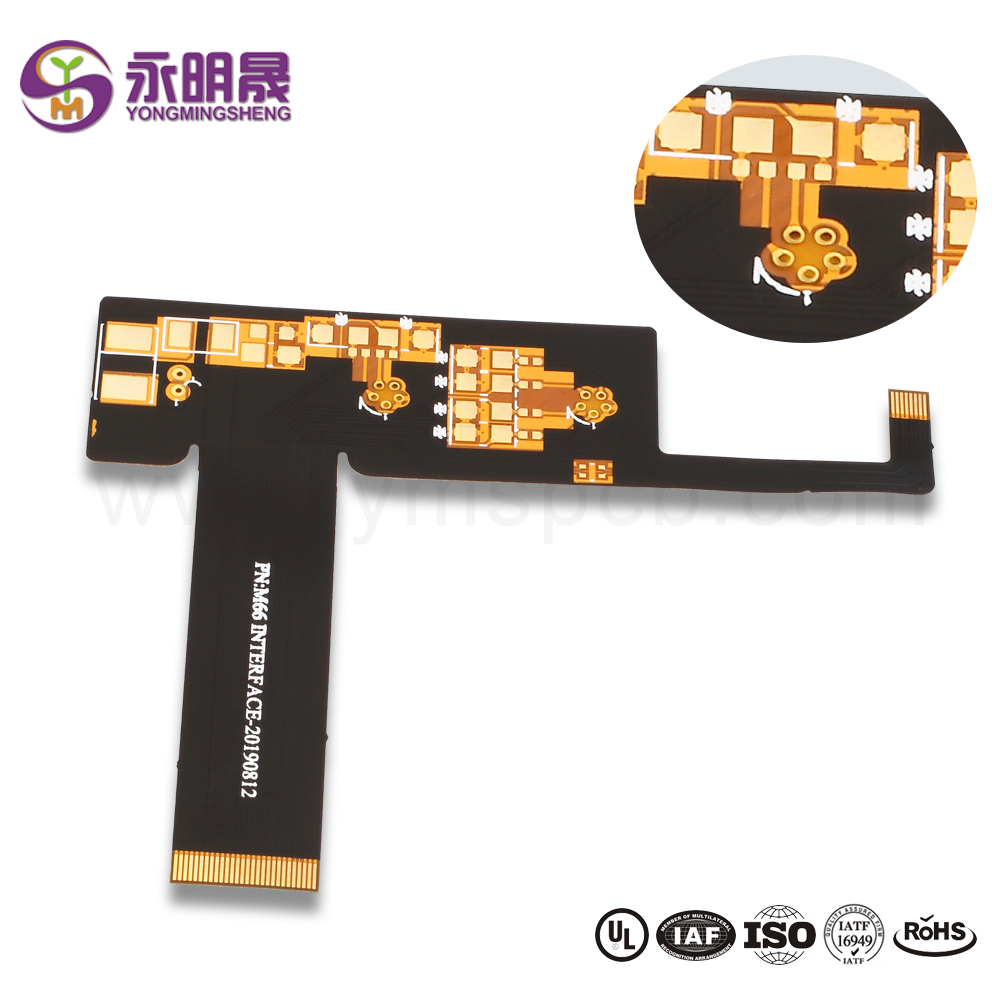

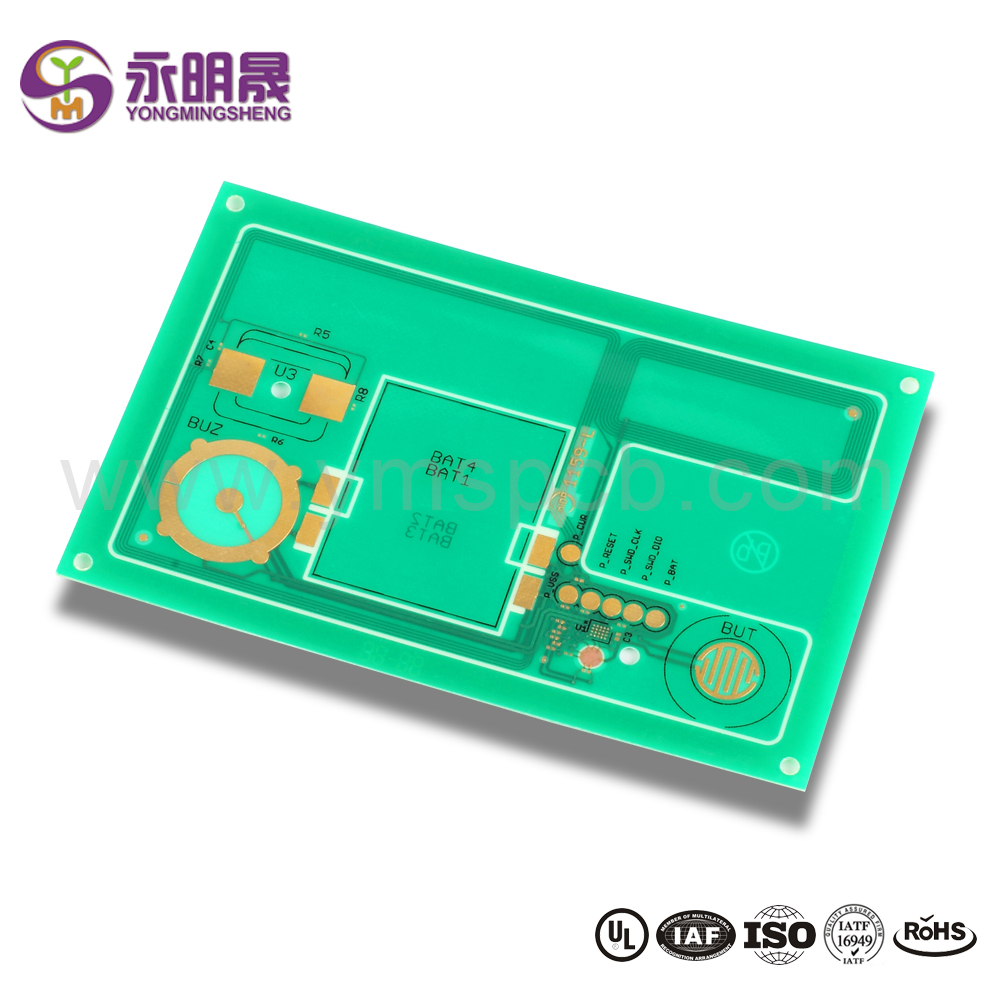

FPC flex board ke sehlahisoa sa mantlha indastering ea elektroniki, se sebelisoang haholo lihlahisoa tsa elektroniki joalo ka lisebelisoa tsa puisano, likhomphutha, lisebelisoa tsa elektroniki tsa likoloi le lisebelisoa tsa indasteri le lisebelisoa tse fapaneng tsa lapeng. Mosebetsi oa eona o ka sehloohong ke ho tšehetsa likarolo tsa potoloho le ho hokahanya likarolo tsa potoloho. FPC soft board ke sehlopha se seholo sa liboto tsa potoloho tse hatisitsoeng. Ho ea ka sebopeho sa liboto tsa potoloho tse hatisitsoeng tsa FPC, bahlahisi ba FPC ba ka aroloa ka mapolanka a mahlakoreng a le mong, a mahlakoreng a mabeli le a mangata ho latela palo ea lihlopha tsa conductor.

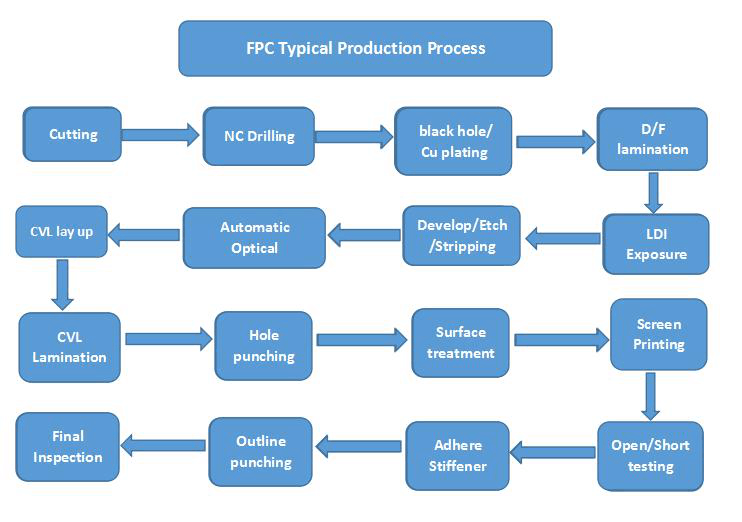

Mokhoa oa tlhahiso ea FPC

FPC e lehlakoreng le le leng:

Single-sided copper clad laminate → Cut Lamination → washing, drying → drilling or punching → screen printing line anti-etching pattern or using dry film → solidify inspection and repairing → etching copper → etching resist ink, drying → washing, drying →Laminate e entsoeng ka koporo e lehlakoreng le le leng → Khaola Lamination, Pholiso ea UV → khatiso ea skrine, pholiso ea UV → ho futhumatsa pele, ho phunya le Sebopeho → teko ea potoloho e khuts'oane e bulehileng → ho hlatsoa, ho omisa → anti-oxidant e koahetsoeng esale pele (e omileng) kapa ho fafatsa moea o chesang o bataletseng → sephutheloana sa tlhahlobo → phepelo ea sehlahisoa se felileng.

FPC ea mahlakore a mabeli:

Copper clad laminate e mahlakoreng a mabeli → Seha Lamination → lamination → CNC cheka → hlahloba, burr hloekisa → PTH → letlapa le tletseng electroplated copper e tshesane → tlhahlobo,hlatsoa → skrine negative Paterone ea potoloho, pheko (filimi e omileng kapa filimi e metsi, ho pepeseha, ho nts'etsopele) → ho hlahloba, ho lokisa → ho roala lithapo tsa mohala → thini ea electroplating (nickel e hanyetsanang le khauta) → hanela enke (filimi e nkang lifoto) → → koporo e kenang → (DE-WETTING) → Hloekisa → mask a solder(filimi e ommeng e ommeng kapa filimi e metsi, ho pepeseha, nts'etsopele, ho folisa mocheso) → ho hloekisa, ho omisa → khatiso ea skrine, ho phekola → ( HASL ) → Profile → ho hloekisa, ho omisa → teko e khutšoanyane ea potoloho → sephutheloana sa tlhahlobo → phepelo ea sehlahisoa se felileng.

FPC flex board process processSheet-by-sheet process:

Sheet by Sheet, e ts'oanang le boto e thata, e sebetsoa ka mokhoa oa nakoana le mohato ka mohato. FPC flexible board e amohela ts'ebetso e ts'oanang le maemo a lisebelisoa tse ts'oanang le boto e thata. Ka mokhoa oa ts'ebetso, ho na le ts'ebetso ea leqephe-ka-sheet: Sheet by Sheet, e ts'oanang le boto e thata, e etsoang ka nako e le 'ngoe ka mohato, kapa Roll to Roll, e leng. ts'ebetso e tsoelang pele ea moqolo oa li-substrates. Lintlha tse ka holimo ke tsebo ea ts'ebetso ea tlhahiso ea boto e bonolo ea FPC ea moetsi oa boto e bonolo, 'me ho ntse ho hlokahala ho laola ka thata mokhoa o mong le o mong oa tlhahiso.

Ithute haholoanyane ka lihlahisoa tsa YMS

Batho le bona baa botsa

Nako ea poso: Apr-15-2022