Ceramic PCB ea ceramic e le 'ngoe le e habeli mahlakoreng a mabeli PCB e etsa Ceramic Substrates| YMS PCB

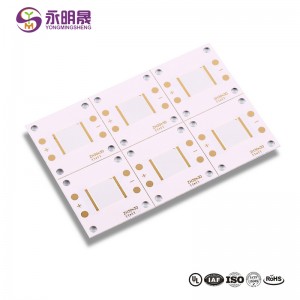

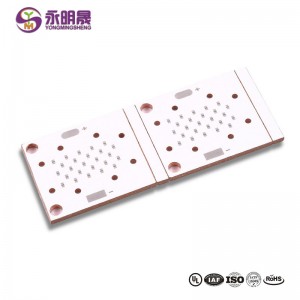

Ceramic PCB: boto ea potoloho ea ceramic substrate

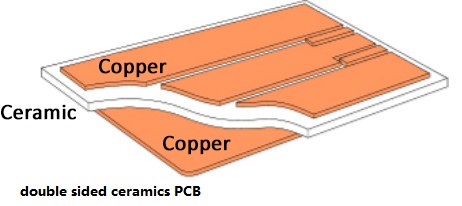

Ceramic Substrate e hlalosa boto e ikhethang ea ts'ebetso moo foil ea aluminium ea koporo e khomaretseng ka kotloloho sebakeng se ka holimo (lehlakore le le leng kapa lehlakoreng le le leng) la alumina (Al2O3) kapa substrate ea aluminium nitride e bobebe (AlN) ka mocheso. Ha ho bapisoa le aluminium e tloaelehileng ea FR-4 kapa substrate ea aluminium e boima bo bobebe, substrate e entsoeng ka bongata e tšesaane e na le ts'ebetso e ikhethang ea ho kenya motlakase, ho tsamaisa mocheso o phahameng, ho soasoa ka mokhoa o ikhethang le matla a phahameng a bond, hape e ka ngolisoa litšoantšo tse ngata tse kang PCB, bokgoni bo makatsang bo teng ba ho phutha. E loketse lintho tse nang le mocheso o phahameng oa mocheso (LED e khanyang haholo, matla a letsatsi), hammoho le boemo ba eona ba leholimo bo matla ka ho fetisisa bo hanyetsanang le maemo a leholimo a mabe a ka ntle. Kenyelletso ea Theknoloji ea Boto ea Potoloho ea Ceramic

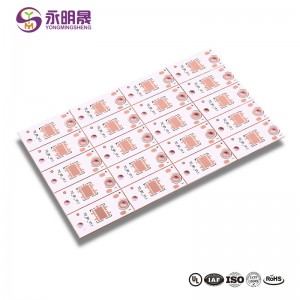

Ke hobane'ng ha u sebelisa lisebelisoa tsa ceramic ho hlahisa liboto tsa potoloho? Liboto tsa potoloho tsa Ceramic li entsoe ka lirafshoa tsa elektroniki 'me li ka etsoa ka libopeho tse fapaneng. Litšobotsi tsa ho hanyetsa mocheso le mocheso o phahameng oa motlakase oa mapolanka a potoloho ea ceramic ke tsona tse hlahelletseng ka ho fetisisa. Melemo ea tahlehelo e tlase ea dielectric le tahlehelo ea dielectric, conductivity e phahameng ea mocheso, botsitso bo botle ba lik'hemik'hale, le coefficient e ts'oanang ea ho atolosa mocheso ho likarolo le tsona li bohlokoa. Ho hlahisa liboto tsa potoloho ea ceramic ho tla sebelisa theknoloji ea LAM, e leng theknoloji ea laser e potlakileng ea ts'ebetso ea metallization. Li sebelisoa tšimong ea LED, li-modules tsa semiconductor tsa matla a phahameng, lihatsetsi tsa semiconductor, li-heaters tsa elektroniki, li-circuits tsa taolo ea matla, li-circuits tsa motlakase, lisebelisoa tse bohlale tsa motlakase, lisebelisoa tsa motlakase tse fetohang khafetsa, li-relays tse tiileng, lisebelisoa tsa elektronike tsa likoloi, puisano, aerospace, le lisebelisoa tsa elektronike tsa sesole.

Melemo ea Ceramic PCB

Ho fapana le setso sa FR-4, lisebelisoa tsa ceramic li na le ts'ebetso e ntle ea maqhubu a phahameng le ts'ebetso ea motlakase, li na le conductivity e phahameng ea mocheso, botsitso ba lik'hemik'hale, botsitso bo botle ba mocheso, le lintho tse ling tseo li-substrates tsa organic li se nang tsona. Ke thepa e ncha e loketseng ea ho paka bakeng sa ho hlahisa lipotoloho tse kholo tse kopaneng le li-module tsa elektroniki tsa matla.

Melemo e ka sehloohong:

conductivity e phahameng ea mocheso.

Tse ling tse tsamaellanang le coefficient ea ho eketsa mocheso.

E matla le e tlase ho hanyetsa filimi ea tšepe ea alumina ceramic circuit board.

The solderability ea substrate e ntle, 'me mocheso oa tšebeliso o phahame.

Insulation e ntle.

Tahlehelo e tlase ea maqhubu a phahameng.

Kopano e phahameng haholo e khoneha.

Ha e na metsoako ea lintho tse phelang, e hanyetsana le mahlaseli a bokahohle, e tšepahala haholo sebakeng sa sefofane, 'me e na le nako e telele ea tšebeletso.

Lera la koporo ha le na lera la oxide mme le ka sebelisoa nako e telele moeeng o fokolang. Li-PCB tsa Ceramic li ka ba molemo 'me tsa sebetsa hantle bakeng sa liboto tsa potoloho tse hatisitsoeng liindastering tsena le tse ling tse ngata, ho latela moralo le litlhoko tsa hau tsa tlhahiso.

Ceramic PCB ke mofuta oa mocheso o tsamaisang phofo ea ceramic le organic binder, 'me mocheso oa mocheso oa organic ceramic PCB o lokiselitsoe ka mocheso oa mocheso oa 9-20W/m. Ka mantsoe a mang, ceramic PCB ke boto ea potoloho e hatisitsoeng e nang le lisebelisoa tsa ceramic base, e leng lisebelisoa tse tsamaisang mocheso haholo tse kang aluminium, aluminium nitride, hammoho le beryllium oxide, e ka etsang hore ho be le phello e potlakileng ea ho fetisetsa mocheso hole le libaka tse chesang le ho qhala. yona hodima bokahodimo bohle. Ho feta moo, ceramic PCB e entsoe ka theknoloji ea LAM, e leng theknoloji ea laser e potlakileng ea ho kenya tšepe. Kahoo ceramic PCB e na le mekhoa e mengata e fapaneng e ka nkang sebaka sa boto ea potoloho e hatisitsoeng ea setso e nang le moaho o sa rarahanang o nang le ts'ebetso e ntlafalitsoeng.

Ntle le MCPCB , haeba u batla ho sebelisa PCB ka khatello e phahameng, insulation phahameng, maqhubu a phahameng, mocheso o phahameng, le phahameng ka tšeptjoang le nyenyane bophahamo ba modumo lihlahisoa tsa elektronike, ka nako eo Ceramic PCB tla ba khetho ea hao molemo ka ho fetisisa.

Hobaneng Ceramic PCB e na le ts'ebetso e ntle joalo? U ka ba le pono e khuts'oane ka sebopeho sa eona sa mantlha mme joale u tla utloisisa.

- 96% kapa 98% Alumina (Al2O3), Aluminium Nitride (ALN), kapa Beryllium Oxide (BeO)

- Lisebelisoa tsa li-conductors: Bakeng sa theknoloji e tšesaane, e teteaneng ea lifilimi, e tla ba silver palladium (AgPd), gold pllladium (AuPd); Bakeng sa DCB (Direct Copper Bonded) e tla ba koporo feela

- Mocheso oa kopo: -55~850C

- Thermal conductivity value: 24W~28W/mK (Al2O3); 150W ~ 240W / mK bakeng sa ALN , 220 ~ 250W / mK bakeng sa BeO;

- Matla a ho hatella:> 7,000 N/cm2

- Karohano ea Voltage (KV/mm): 15/20/28 bakeng sa 0.25mm/0.63mm/1.0mm ka ho latellana

- Konefite ya katoloso ya mocheso(ppm/K): 7.4 (tlasa 50~200C)

Mefuta ea li-PCB tsa ceramic

1. Mocheso o phahameng oa ceramic PCB

2. Mocheso o tlaase oa ceramic PCB

3.Thick filimi ceramic PCB

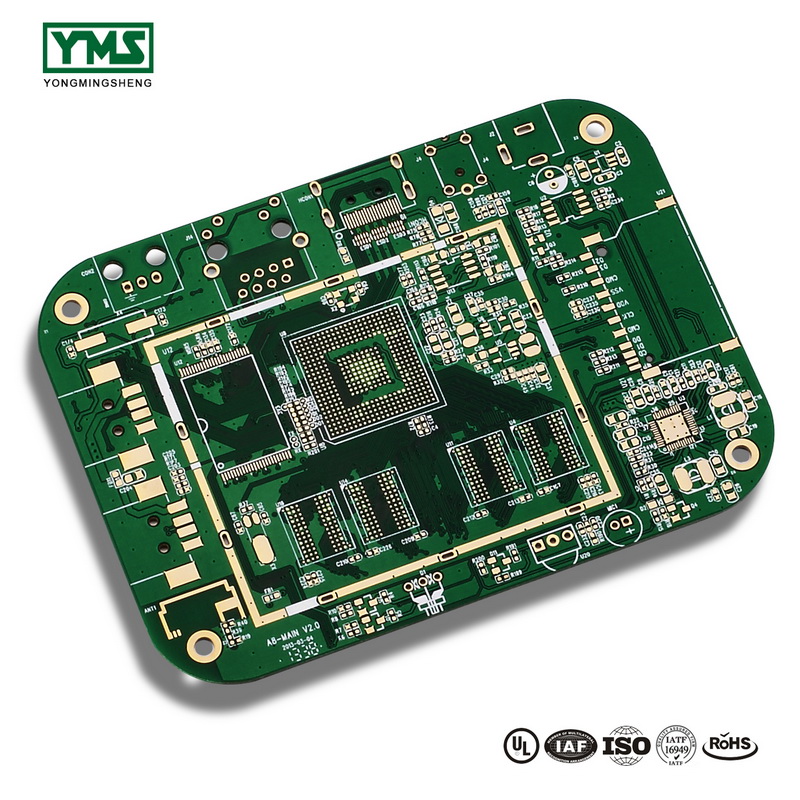

Bokhoni ba ho etsa YMS Ceramic PCB:

| Kakaretso ea bokhoni ba tlhahiso ea YMS Ceramic PCB | ||

| Tšobotsi | bokhoni | |

| Palo ea Lera | 1-2L | |

| Lintho tse bonahalang le Botenya | Al203: 0.15, 0.38,0.5,0.635,1.0,1.5,2.0mm joalo-joalo. | |

| SEBE: 0.25,0.38,0.5,1.0mm joalo-joalo. | ||

| AIN: 0.15, 0.25,0.38,0.5,1.0mm joalo-joalo. | ||

| Thermal conductivity | Al203: Min. 24 W/mk ho fihla ho 30W/mk | |

| SEBE: Min. 85 W/mk ho fihla ho 100W/mk | ||

| AIN: Min. 150 W/mk ho fihla ho 320 W/mk | ||

| Al2O3 | Al2O3 e na le khanya e betere ea khanya - e etsa hore e tšoanele lihlahisoa tsa LED. | |

| SEBE | SiN e na le CTE e tlase haholo. Ha e kopantsoe le Matla a Phahameng a phahameng e ka mamella ts'oaetso e matla ea mocheso. | |

| AlN | AlN e na le superior Thermal Conductivity - e etsa hore e tšoanelehe bakeng sa lisebelisoa tsa motlakase tse phahameng haholo tse hlokang substrate e ntle ka ho fetisisa e ka khonehang. | |

| Botenya ba Boto | 0.25mm-3.0mm | |

| koporo botenya | 0.5-10OZ | |

| Bophara ba mola le Bonyane | 0.075mm/0.075mm(3mil/3mil) | |

| Tse khethehileng | Countersink, Counterbore ho cheka.etc. | |

| Mets phethahetse Drilled Size | 0.15mm (6mil) | |

| Lisebelisoa tsa li-conductors: | Bakeng sa theknoloji e tšesaane, e teteaneng ea lifilimi, e tla ba silver palladium (AgPd), gold pllladium (AuPd),Platinum For DCB (Direct Copper Bonded) e tla ba koporo feela. | |

| Holim qeta | HASL, E etella pele mahala HASL, ENIG, qoelisoa Tin, OSP, qoelisoa Silver, Gold monoana, Electroplating Hard Khauta, khetla OSP , ENEPIG.etc. | |

| Mask ea solder | Green, Red, Yellow, Blue, White, Black, Pherese, Matte Black, Matte tala.etc. | |

| bentšitsoe | Ra <0.1 um | |

| lapped | Ra <0.4 um | |

Ithute haholoanyane ka lihlahisoa tsa YMS

Bala litaba tse ling