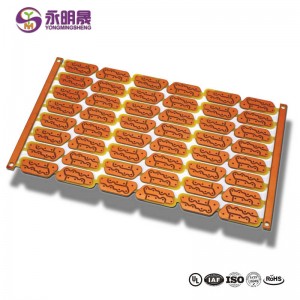

PCB-ga caadiga ah ee PCB Countersink ee laba-geesoodka ah | YMSPCB

Hordhac Wareegtada Guddiga Wareegga

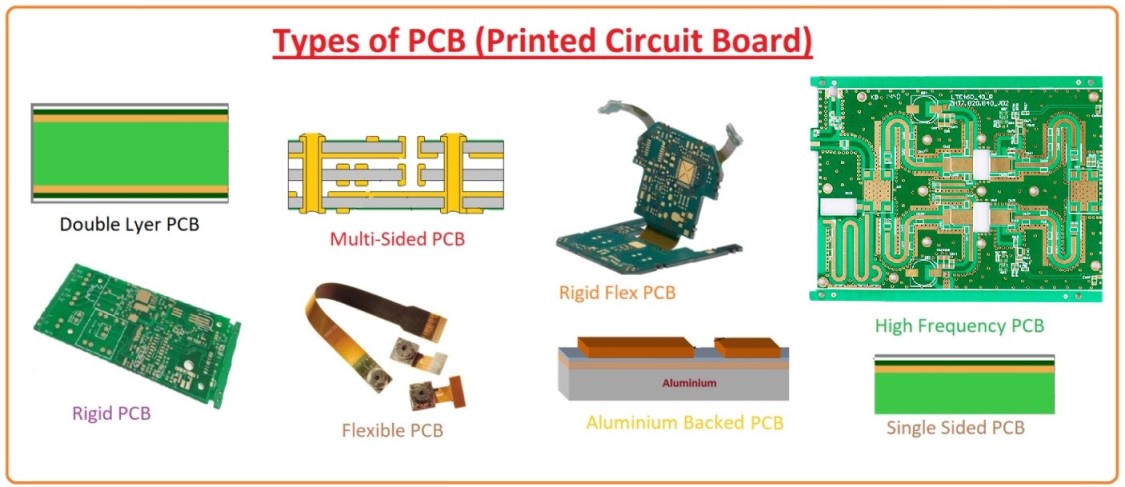

A wareegsan oo mechanically supports and electrically connects electrical or electronic components using conductive tracks, pads and other features etched from one or more sheet layers of copper laminated onto and/or between sheet layers of a non-conductive substrate. Components are generally soldered onto the PCB to both electrically connect and mechanically fasten them to it.PCBs can be single-sided (one copper layer), double-sided (two copper layers on both sides of one substrate layer), or multi-layer (outer and inner layers of copper, alternating with layers of substrate). Multi-layer PCBs allow for much higher component density, because circuit traces on the inner layers would otherwise take up surface space between components. The rise in popularity of multilayer PCBs with more than two, and especially with more than four, copper planes was concurrent with the adoption of surface mount technology.

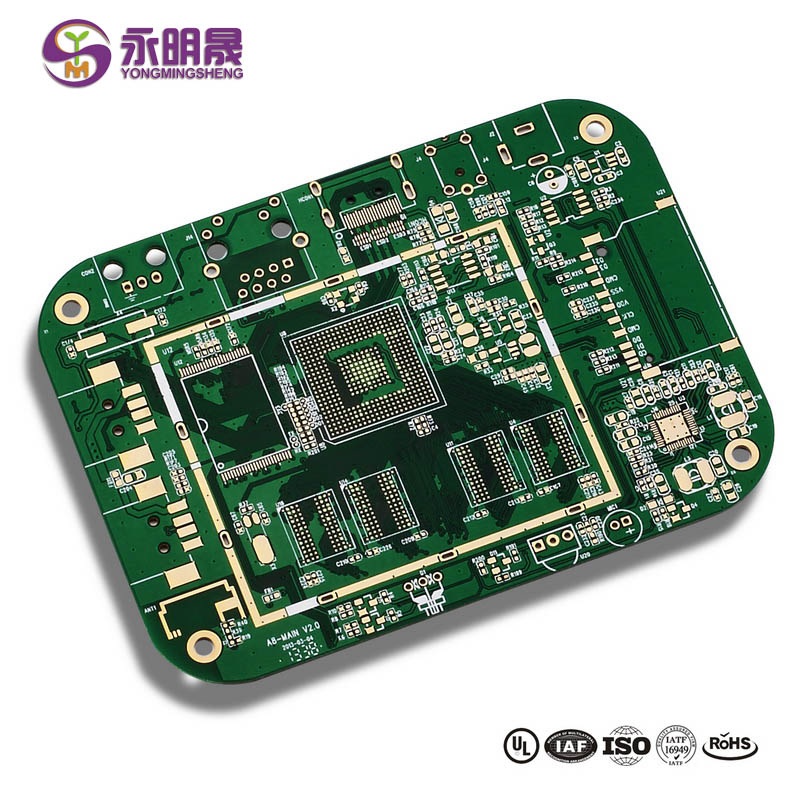

Looxyada wareegyada laba-geesoodka ah ayaa xoogaa ka dhib badan PCB-ga hal dhinac ah. Looxyadani waxay ka kooban yihiin hal lakab oo ah substrate-ka hoose. Si kastaba ha ahaatee, waxay ka kooban yihiin lakabyo conductive ah dhinac kasta. Waxay u isticmaalaan naxaas sida walxo dhaq-dhaqaaq ah. Aan sii muquunno gudaha PCB-ga laba-geesoodka ah si aan wax badan u barano!

Qaab-dhismeedka iyo Agabka PCB-ga laba-geesoodka ah

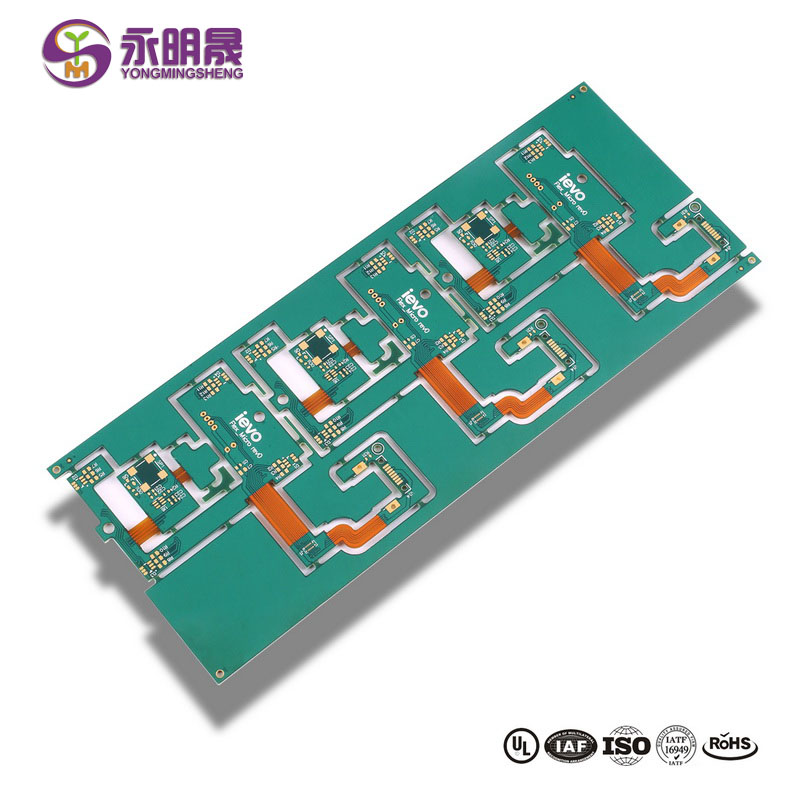

Walxaha PCB-ga laba-geesoodka ah way kala duwanaan karaan iyadoo lagu saleynayo nooca mashruuca. Si kastaba ha ahaatee, walxaha asaasiga ahi waxay ku dhow yihiin isku mid dhammaan looxyada wareegga. Si kastaba ha ahaatee, qaab dhismeedka PCB wuu ku kala duwan yahay nooca ilaa nooca.

Substrate: waa shayga ugu muhiimsan ee laga sameeyay fiberglass. Waxaad u qaadan kartaa sidii qalfoofka PCB-ga.

Lakabka Copper: Waxay noqon kartaa mid bireed ama dahaar buuxa oo naxaas ah. Taasi waa sababta ay ku xiran tahay nooca guddiga. Natiijada kama dambaysta ahi waa isku mid haddii aad isticmaashid dahaarka bireed ama naxaasta. Looxyada wareegga laba-geesoodka ah waxay ka kooban yihiin lakab naxaas ah oo labada dhinac ah.

Maaskarada Alxan: Waa lakabka difaaca ee polymer. Sidaa darteed, waxay ka hortagtaa naxaasta wareegga gaaban. Waxaad u tixgelin kartaa sida maqaarka guddiga wareegga. Alxanka PCB-ga laba-geesoodka ah waa tallaabo aad muhiim u ah adkeysiga.

Shaashadda xariirta: waa qaybta ugu dambeysa ee muraayadda xariirta. Inkastoo aysan wax door ah ku lahayn shaqeynta guddiga wareegga. Soo-saareyaashu waxay u isticmaalaan inay muujiyaan nambarada qaybta. Nambarada qaybuhu aad bay muhiim ugu yihiin ujeedooyinka tijaabada. Intaa waxaa dheer, waxaad daabacan kartaa calaamadaha shirkaddaada ama macluumaadka kale oo qaab qoraal ah.

Faa'iidooyinka iyo Khasaaraha ay leeyihiin Guddiyada Wareegga ee Laba-geesoodka ah

Waa kuwan qaar ka mid ah faa'iidooyinka iyo khasaarooyinka looxyada wareegyada daabacan ee laba-geesoodka ah:

Faa'iidooyinka Guddiyada Wareegga ee Laba-dhinac ah

Tayada Sare: Qorshaynta iyo naqshadaynta PCB-gan waxay u baahan yihiin shaqo fiican. Taas oo keentay loox-wareeg tayo sare leh.

Meel bannaan oo ku filan Qaybaha: Waxay haysaa boos badan oo qaybaha ah. Sababtoo ah labada dhinac ee lakabka ayaa ah kuwa qabanaya.

Ikhtiyaar Naqshad Badan: Waxay leedahay lakabyo wax-qabad oo labada dhinac ah. Waxaad ku dhejin kartaa qaybaha elektarooniga ah ee kala duwan labada dhinacba. Markaa waxaad haysataa doorashooyin badan oo naqshadeed.

Dajinta iyo Qulqulka Hadda: Markaad u isticmaalayso lakab hoose, waxaad u isticmaali kartaa quusinta iyo soo saarida hadda.

Isticmaalka: waxtarkeeda awgeed, waxaad u isticmaali kartaa codsiyo badan.

Faa'iido darrada looxyada wareeg ee laba-geesoodka ah

Kharashka Sare: Ka dhigista labada dhinacba kuwa dhaq-dhaqaaqa, waxay ku timaadaa kharash yar oo sarreeya.

Naqshadeeye Xirfad leh ayaa Loo Baahan Yahay: Waxa ku lug leh hab-soo-saar PCB-ga samayntiisa xoogaa adag oo laba-geesood ah. Sidaa darteed, waxaad u baahan tahay injineero aad u yaqaana wax soo saarkeeda.

Waqtiga Wax-soo-saarka: Waqtiga wax-soo-saarku wuu ka badan yahay hal dhinac oo PCB ah sababtoo ah kakanaanta.

Codsiga looxyada wareegyada laba-geesoodka ah

Noocan ah guddiga wareegga wuxuu kordhiyaa cufnaanta wareegga. Iyagu sidoo kale aad bay u dabacsan yihiin. Ku dhawaad dhammaan soosaarayaasha PCB-ga laba-geesoodka ah waxay ku isticmaalaan qalabyo badan oo elegtarooniga ah. Hoos waxaa ku qoran qaar ka mid ah kiisaska isticmaalka cajiibka ah ee looxyada wareegyada laba-geesoodka ah:

HVAC iyo nalalka LED

Nidaamka xakamaynta gaadiidka

Boodhadhka baabuurta

Xakamaynta wareejinta iyo beddelka Awoodda

Nidaamiyeyaal iyo sahay koronto

Si loo tijaabiyo loona kormeero qalab kala duwan

Daabacadaha iyo nidaamyada taleefanka gacanta

Mashiinnada wax lagu iibiyo.

YMS Awoodda wax soo saarka PCB ee caadiga ah:

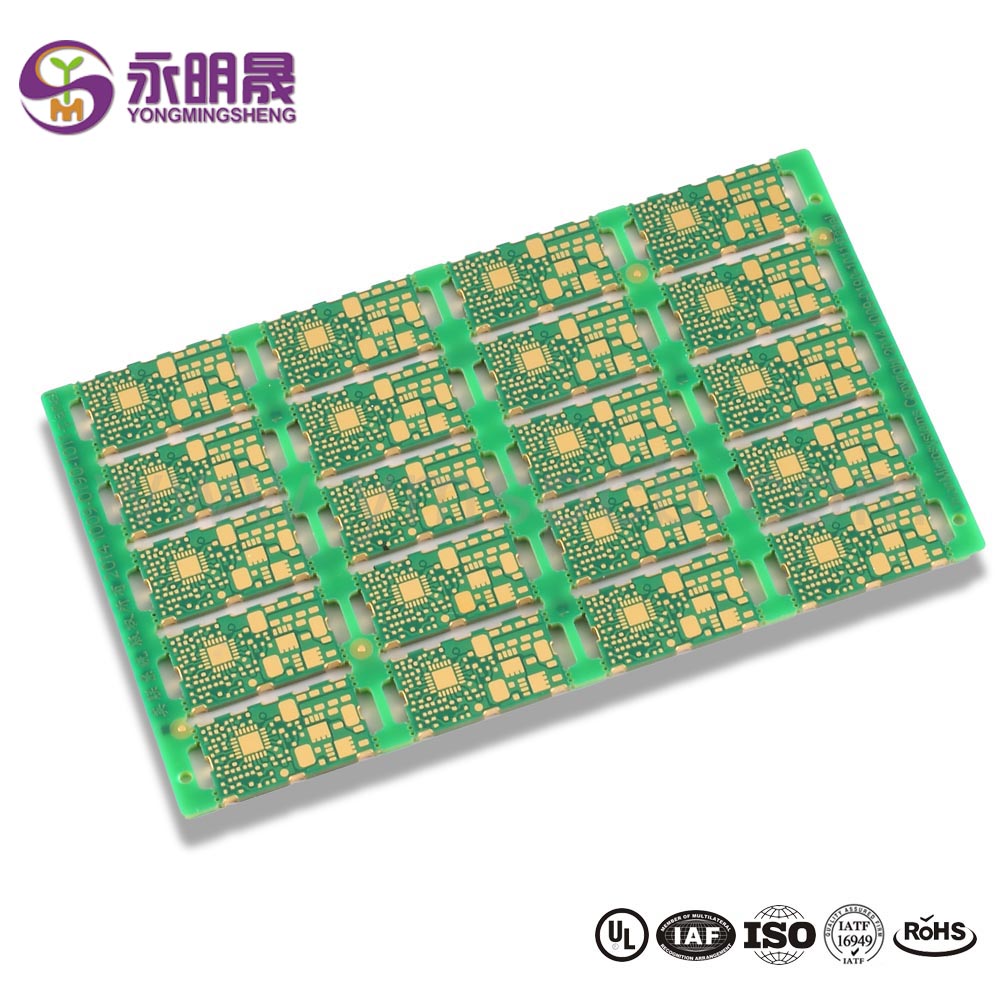

| Guudmarka awooda wax soosaarka PCB-ga ee YMS | ||

| Muuqaalka | awoodaha | |

| Tirinta Lakabka | 1-60L | |

| Teknoolojiyada PCB ee Caadiga ah | Iyada oo loo marayo godka Qaybta Aspect 16: 1 | |

| aasay oo indho la 'via | ||

| Iskujir | Waxyaabaha Frequency High sida RO4350B iyo FR4 Mix iwm. | |

| Waxyaabaha Xawaaraha Sare leh sida M7NE iyo FR4 Mix iwm. | ||

| Waxyaabaha | CEM- | CEM-1; CEM-2 ; CEM-4 ; CEM-5. iyo wixii la mid ah |

| FR4 | EM827, 370HR, S1000-2, IT180A, IT158, S1000 / S1155, R1566W, EM285, TU862HF, NP170G iwm | |

| Xawaare sare | Megtron6, Megtron4, Megtron7, TU872SLK, FR408HR, N4000-13 Series, MW4000, MW2000, TU933 iwm | |

| Joogtaynta Sare | Ro3003, Ro3006, Ro4350B, Ro4360G2, Ro4835, CLTE, Genclad, RF35, FastRise27 iwm | |

| Qaar kale | Polyimide, Tk, LCP, BT, C-ply, Fradflex, Omega, ZBC2000, PEEK, PTFE, dhoobada ku saleysan iwm | |

| Dhumucdiisuna | 0.3mm-8mm | |

| Dhumucda Maxaxda | 10OZ | |

| Ballaaran khadka ugu yar iyo Booska | 0.05mm / 0.05mm (2mil / 2mil) | |

| GAROONKA BGA | 0.35mm | |

| Min Qiyaas ahaan qodan Farsamo | 0.15mm (6mil) | |

| Saamiga saamiga illaa daloolka | 16 : 1 | |

| Dhammeystirka dusha sare | HASL, Lead free HASL, ENIG, Immersion Tin, OSP, Immersion Silver, Finger Gold, Electroplating Gold Gold, Selective OSP , ENEPIG.etc. | |

| Via Buuxi Xulashada | Khadka la mariyo ayaa lagu dhajiyay oo lagu buuxiyay epoxy tabin ama tabin la'aan ah ka dibna la daboolay oo la dul saaray (VIPPO) | |

| Naxaas la buuxiyey, lacagna la buuxiyey | ||

| Diiwaangelinta | M 4milyan | |

| Maaskaro Alxan | Cagaar, Casaan, Jaale, Buluug, Caddaan, Madoow, Midabbo, Matte Madow, Matte green. Iwm. | |

Video

Baro wax badan oo ku saabsan alaabta YMS

Warar dheeraad ah ka akhriso

Waa maxay PCB-ga laba-geesoodka ah?

PCB-ga laba-geesoodka ah ama laba-lakabka ah ee daabacan ee wareegga waa ka adag yahay PCB-yada Hal dhinac ah. Noocyada PCB-ga waxay leeyihiin hal lakab oo ah substrate-ka salka ah laakiin lakabka korantada (naxaasta) ee labada dhinac ee substrate-ka. Maaskarada alxanka ayaa lagu dabaqaa labada dhinac ee looxa.

Waa maxay PCB-da lakabka ah ee loo isticmaalo?

Qalabka Elektarooniga ah ee Macmiilka

Sidee loo sameeyaa lakabka labalaabka ah ee PCB?

FR4+Naxaas+Alxanka+shashada xariirta

Waa maxay faraqa u dhexeeya hal lakab iyo PCB-da lakabka leh?

Shaxda PCB-ga ee hal dhinac ah oo inta badan la isticmaalo Shabakadda Daabacaadda (Shaashada Daabacaada), taas oo ah, iska caabbin dusha naxaasta ah, Ka dib markaad dhejiso, calaamadee caabbinta alxanka, ka dibna ku dhammee daloolka iyo qaabka qaybta adigoo feeray.

Looxyada wareegyada daabacan ee hal dhinac ah ayaa si weyn loogu isticmaalaa elektarooniga badan, halka looxyada wareegyada laba-geesoodka ah inta badan loo isticmaalo elektarooniga tignoolajiyada sare.

Looxa wareegyada daabacan ee hal dhinac ah ayaa caadi ahaan loo adeegsadaa qalabyo kala duwan oo elegtarooniga ah iyo codsiyada, oo ay ku jiraan nidaamyada kamaradaha, daabacadaha, qalabka raadiyaha, xisaabiyeyaasha, iyo wax ka badan.