xawaaraha sare PCB POFV galinta lumin test enepig| YMSPCB

Waa maxay PCB Xawaaraha Sare?

"Xawaaraha Sare" waxaa guud ahaan loo fasiraa in loola jeedo wareegyada halka dhererka calaamada kor u kaca ama hoos u dhacaya ay ka weyn tahay qiyaastii lix-meelood meel dhererka xariiqda gudbinta oo ka weyn dhererka xariiqda gudbinta, ka dibna dhererka xariiqda gudbintu wuxuu muujinayaa dabeecadda xariiqda.

In a PCB xawaaraha sare , markii u kaca waa si dhakhso ah oo ku filan in bandwidth ee signalka digital kordhin karaa MHz ama GHz firikuwensiyada sare. Marka tani dhacdo, waxaa jira dhibaatooyin calaamado gaar ah oo la ogaan doono haddii loox aan loo qaabayn iyadoo la adeegsanayo sharciyada naqshadeynta PCB ee xawaaraha sare leh. Gaar ahaan, waxaa laga yaabaa in la ogaado:

1. Gariir weyn oo aan la aqbali karin. Tani waxay guud ahaan dhacdaa marka raadadku aanay ballaadhnayn, inkasta oo aad u baahan tahay inaad ka taxadirto marka aad samaynayso raadadkaaga ballaaran (eeg qaybta Impedance Contorl ee Nakhshadda PCB ee hoose). Haddii garaaca ku meel gaadhka ahi uu aad u weyn yahay, waxa aad heli doontaa xatooyo weyn ama hoos u dhigida is beddelka signalkaaga.

2.Hadal adag. Marka uu xawliga calaamaduhu kordho (sida, marka uu wakhtiga kor u kaca hoos u dhaco), hadal-is-dhaafsigu waxa uu noqon karaa mid aad u weyn sida waayo-aragnimada hadda la soo kiciyay ay la kulanto awood yaraan.

3. Milicsi off of darawalka iyo qaybaha qaata. Calaamadahaagu waxay ka turjumi karaan qaybaha kale mar kasta oo ay jirto ismaandhaaf la'aan. Haddii is-waafajinta is-waafajinta ay noqoto mid muhiim ah iyo in kale waxay u baahan tahay in la eego impedance gelinta, culayska culeyska, iyo xadhkaha gudbinta cilladda sifada isku xidhka. Waxaad wax badan oo arrintan ku saabsan ka akhriyi kartaa qaybta soo socota.

4.Dhibaatooyinka daacadnimada awooda (PDN ripple, boobka dhulka, iwm.). Tani waa qayb kale oo ah dhibaatooyinka aan laga maarmi karin ee naqshad kasta. Si kastaba ha ahaatee, ripple PDN ee ku meel gaadhka ah iyo EMI kasta oo ka dhalata si weyn ayaa loo yarayn karaa iyada oo loo marayo qaabaynta saxda ah iyo cabbiraadaha kala-goynta. Waxaad ka akhrisan kartaa wax badan oo ku saabsan naqshadaynta xidhitaanka PCB ee xawaaraha sare leh hagahan dambe.

5. Dhaqdhaqaaq xooggan oo la sameeyay EMI. Daraasadda xallinta dhibaatooyinka EMI waa mid ballaaran, labadaba heerka IC iyo heerka naqshadaynta PCB ee xawaaraha sare leh. EMI asal ahaan waa hannaan is-dhaafsi; Haddii aad u qaabayso guddigaaga si uu u yeesho difaac adag oo EMI ah, markaas waxay sii dayn doontaa EMI ka yar. Mar labaad, inta badan tani waxay hoos ugu dhacdaa naqshadaynta kaydinta PCB ee saxda ah.

PCB-yada soo noqnoqda badanaa waxay bixiyaan soo noqnoqda inta u dhaxaysa 500MHz ilaa 2 GHz, kaas oo buuxin kara baahiyaha naqshadaha PCB-ga xawaaraha sare leh, microwave-ka, soo noqnoqda raadiyaha, iyo codsiyada mobaylka. Marka inta jeer ee uu ka sarreeyo 1 GHz, waxaan ku qeexi karnaa inta jeer ee sare.

Kakanaanta qaybaha elektiroonigga ah iyo furayaasha ayaa si joogto ah u kordhaya maalmahan waxayna u baahan yihiin heerarka socodka signalada degdega ah. Markaa, inta jeer ee gudbinta sare ayaa loo baahan yahay. PCB-yada soo noqnoqda ayaa aad u caawiya marka la isku daro shuruudaha calaamadaha gaarka ah ee qaybaha elektiroonigga ah iyo alaabooyinka leh faa'iidooyinka sida waxtarka sare, iyo xawaaraha degdega ah, hoos u dhigista, iyo sifooyinka tamarta korontada ee joogtada ah.

PCB-yada soo noqnoqda waxaa inta badan loo adeegsadaa raadiyaha iyo codsiyada dhijitaalka ah ee xawaaraha sare leh, sida isgaarsiinta 5G wireless, dareemayaasha radar baabuurta, hawada hawada, satalaytka, iwm. Laakiin waxaa jira arrimo badan oo muhiim ah oo la tixgeliyo marka la soo saarayo PCB-yada soo noqnoqda.

Naqshadaynta lakabyo badan

Caadi ahaan waxaanu isticmaalnaa PCB-yada lakabyo badan leh ee naqshadaha PCB-ga ee soo noqnoqda. PCB-yada lakabyada badan leh waxay leeyihiin cufnaanta isku dhafka iyo mugga yar, taas oo ka dhigaysa mid aad ugu habboon xirmooyinka saameynta. Iyo looxyada lakabyo badan ayaa ku habboon in la gaabiyo xiriirka ka dhexeeya qaybaha elektaroonigga ah iyo hagaajinta xawaaraha gudbinta calaamadaha.

Naqshadaynta diyaaradda dhulka waa qayb muhiim ah oo ka mid ah codsiyada soo noqnoqda sare sababtoo ah kaliya maaha inay ilaaliso tayada calaamadaha laakiin sidoo kale waxay kaa caawineysaa yaraynta shucaaca EMI.

1. Ogolaanshaha la waafajiyay.

2.Attenuation hooseeya ee gudbinta calaamadaha hufan.

3.Dhismaha isku midka ah oo leh dulqaad hoose oo dhumucdiisuna tahay dahaarka iyo joogtada ah dielectric. Baahida loo qabo badeecadaha PCB-ga ee xawaaraha-sare iyo xawaaraha sare leh ayaa si degdeg ah u kaca maalmahan. Sida soo saaraha PCB , YMS waxa ay diiradda saaraysaa sidii ay macaamiisha u siin lahayd wax-soo-saar PCB-ga caadiga ah oo la isku halayn karo oo tayo sare leh. Haddii aad wax dhib ah kala kulanto naqshadaynta PCB ama soo saarista PCB, fadlan xor u noqo inaad nala soo xidhiidho.

| dulmar guudmar awoodaha wax soo saarka ee xawaaraha sare ee YMS PCB | ||

| Muuqaalka | awoodaha | |

| Tirinta Lakabka | 2-30L | |

| Available Xawaare sare PCB Technology | Iyada oo loo marayo godka Qaybta Aspect 16: 1 | |

| aasay oo indho la 'via | ||

| Looxyada Dielectric isku dhafan ( Xawaaraha Sare Waxyaabaha + FR-4 isku dhafka ah) | ||

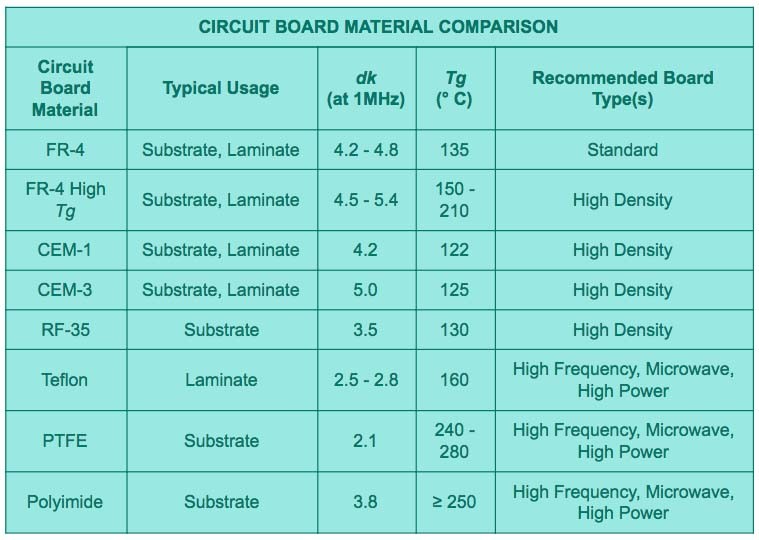

| Habboon Xawaare sareQalabka la heli karo: M4, taxane M6, N4000-13 taxane, FR408HR, TU862HF TU872SLKSP, EM828, iwm | ||

| Dulqaad adag oo ku saabsan Astaamaha RF Halis ah:+/- .0005 ″ dulqaadka caadiga ah ee 0.5oz naxaas aan la dahaadhayn | ||

| Dhismayaasha godad badan, qadaadiicda Copper iyo slugs, Metal Core & Metal Back, Laminates thermally conductive Laminates, Edge Plating, iwm. | ||

| Dhumucdiisuna | 0.3mm-8mm | |

| Ballaaran khadka ugu yar iyo Booska | 0.075mm/0.075mm(3mil/3mil) | |

| GAROONKA BGA | 0.35mm | |

| Min laser Qodmay Size | 0.075mm (3nil) | |

| Min Qiyaas ahaan qodan Farsamo | 0.15mm (6mil) | |

| Saamiga saamiga ee daloolka laser | 0.9: 1 | |

| Saamiga saamiga illaa daloolka | 16: 1 | |

| Dhammeystirka dusha sare | Habboon Xawaare saredhamaado urface PCB: Electroless Nikkel, Immersion Gold, ENEPIG, HASL free Lead, Immersion Silver | |

| Via Buuxi Xulashada | Khadka la mariyo ayaa lagu dhajiyay oo lagu buuxiyay epoxy tabin ama tabin la'aan ah ka dibna la daboolay oo la dul saaray (VIPPO) | |

| Naxaas la buuxiyey, lacagna la buuxiyey | ||

| Laser iyadoo la adeegsanayo naxaas dahaadhay | ||

| Diiwaangelinta | M 4milyan | |

| Maaskaro Alxan | Cagaar, Casaan, Jaale, Buluug, Caddaan, Madoow, Midabbo, Matte Madow, Matte green. Iwm. | |

Baro wax badan oo ku saabsan alaabta YMS

Warar dheeraad ah ka akhriso

Video