Biraha laba-geesoodka ah ee pcb Copper Base High Power Birta core Board| YMS PCB

Waa maxay Multi Layers MCPCB?

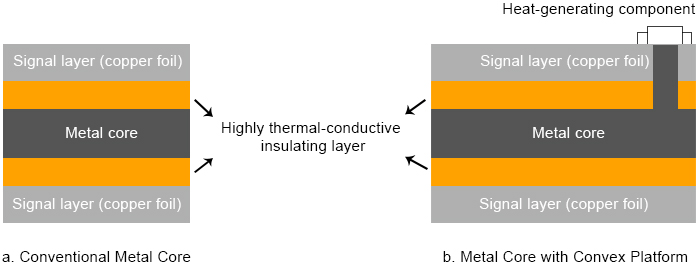

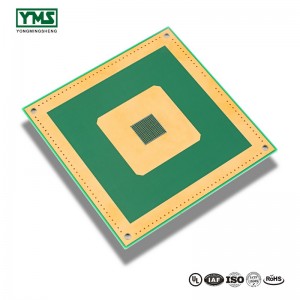

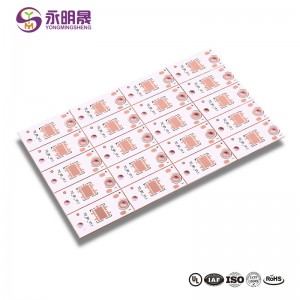

Qalabka Wareegga Daabacan ee Birta ah (MCPCB) , oo sidoo kale loo yaqaan PCB kulaylka PCB -ga biraha taageera, waa nooc ka mid ah PCB kaas oo leh walxo bir ah oo saldhig u ah qaybta fidinta kulaylka ee looxa. Birta qaro weyn (ku dhawaad had iyo jeer aluminium ama naxaas) waxay dabooshaa 1 dhinac ee PCB-ga. Xuddunta birtu waxay noqon kartaa tixraac ku saabsan birta, iyagoo ku yaal meel dhexe ama dhabarka looxa. Ujeedada udub dhexaadka MCPCB waa in lagu jiheeyo kulaylka qaybaha guddiga muhiimka ah iyo meelaha aan muhiimka ahayn sida taageeridda kulaylka birta ama xudunta macdan. Biraha saldhigga ah ee MCPCB waxaa loo isticmaalaa beddelka looxyada FR4 ama CEM3.

Birta xudunta daabacan ee looxa (MCPCB) sidoo kale loo yaqaan PCB kulaylka, waxay ku daraysaa walxo bir ah sida saldhigeeda oo ka soo horjeeda FR4-dhaqameedka, ee kala qaybsanaanta kulaylka ee looxa. Kuleylka ayaa kor u kaca sababtoo ah qaybaha elektarooniga ah qaarkood inta lagu jiro hawlgalka looxa. Ujeedada birta ayaa ah in kulaylkan laga weeciyo qaybaha muhiimka ah ee looxa oo loo jeediyo meelaha aan muhiimka ahayn sida taageerka kulaylka birta ama xudunta birta ah. Markaa, PCB-yadani waxay ku habboon yihiin maaraynta kulaylka.

MCPCB-da lakabyo badan, lakabyada ayaa si siman loogu qaybin doonaa dhinac kasta oo ka mid ah xudunta birta. Tusaale ahaan, looxa 12-lakab ah, xudunta birta ahi waxay ahaan doontaa xarunta oo leh 6 lakab oo sare ah iyo 6 lakab oo hoose ah.

MCPCB-yada waxaa sidoo kale loo tixraacaa sida substrate metallic substrate (IMS), PCB-yada biraha dahaaran (IMPCBs), PCB-yada kulaylka leh, iyo PCB-yada biraha-xidhan. Maqaalkan, waxaanu adeegsan doonaa MCPCB-ga soo gaabinta si aan uga fogaano madmadowga.

MCPCB-yadu waxa ay ka samaysan yihiin lakabyo kulaylka leh, taarikada birta ah, iyo birta birta ah ee birta ah. Tilmaamaha naqshadeynta dheeraadka ah / talooyinka loogu talagalay Birta Muhiimka ah (Aluminium iyo Copper) Guddiyada Wareegga ee Daabacan ayaa la heli karaa marka la codsado; kala xidhiidh YMSPCB kell@ymspcb.com.ama Wakiilkaaga Iibka si aad wax badan u waydiiso.

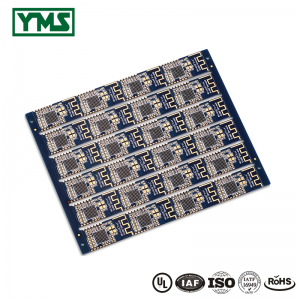

YMS Multi Layers PCB muhiimka ah birta:

| YMS Multi Layers Dulmar guudmar awoodaha wax soo saarka PCB birta xudunta u ah | ||

| Muuqaalka | awoodaha | |

| Tirinta Lakabka | 1-8L | |

| Base Waxyaabaha | Aluminium/Naxaas/ Birta Daawaha | |

| Dhumucdiisuna | 0.8 mm min | |

| Dhumucda qadaadiicda | 0.8-3.0mm | |

| Ballaaran khadka ugu yar iyo Booska | 0.05mm / 0.05mm (2mil / 2mil) | |

| GAROONKA BGA | 0.35mm | |

| Lacagta qadaadiicda Min Copper | 1.0mm daq | |

| Min Qiyaas ahaan qodan Farsamo | 0.15mm (6mil) | |

| Saamiga saamiga illaa daloolka | 16 : 1 | |

| Dhammeystirka dusha sare | HASL, Lead free HASL, ENIG, Immersion Tin, OSP, Immersion Silver, Finger Gold, Electroplating Gold Gold, Selective OSP , ENEPIG.etc. | |

| Via Buuxi Xulashada | Khadka la mariyo ayaa lagu dhajiyay oo lagu buuxiyay epoxy tabin ama tabin la'aan ah ka dibna la daboolay oo la dul saaray (VIPPO) | |

| Naxaas la buuxiyey, lacagna la buuxiyey | ||

| Diiwaangelinta | M 4milyan | |

| Maaskaro Alxan | Cagaar, Casaan, Jaale, Buluug, Caddaan, Madoow, Midabbo, Matte Madow, Matte green. Iwm. | |

Sababaha ugu muhiimsan ee isticmaalka looxyada saldhigga naxaasta

1. Kuleyl wanaagsan oo daata:

Waqtigan xaadirka ah, qaar badan oo 2 lakab ah iyo guddiyo badan ayaa faa'iido u leh cufnaanta sare iyo awoodda sare, laakiin kuleylka kuleylka ayaa adag inuu noqdo. Qalabka caadiga ah ee PCB sida FR4, CEM3 waa kireeyaha kulaylka liidata, dahaarka ayaa u dhexeeya lakabyada, iyo sii daynta kulaylku ma bixi karto. Kuleyliyaha maxalliga ah ee qalabka elektiroonigga ah lama baabi'in karo waxay keeni doontaa in heerkul sare uu xumaado qaybaha elektiroonigga ah. Laakiin waxqabadka kulaylka wanaagsan ee PCB-ga xudunta u ah ayaa xallin kara dhibaatadan kuleylka kuleylka.

2. xasilloonida cabbirka:

PCB-ga xudunta u ah biraha sida cad aad buu uga xasilan yahay cabbir ahaan marka loo eego looxyada daabacan ee alaabta dahaadhka ah. Aluminium-saldhiga aluminiumka iyo aluminium sandwich board ayaa kuleyliya laga bilaabo 30 ℃ ilaa 140 ~ 150 ℃, cabbirkeedu wuxuu isbeddelaa 2.5 ~ 3.0%.

3. Sabab kale:

Guddiga saldhigga Copper wuxuu leeyahay saameyn gaashaan oo beddelaya substrate dhoobada jilicsan, sidaas darteed waxay ku nasan kartaa isticmaalka tignoolajiyada korka ee korka si loo yareeyo aagga dhabta ah ee waxtarka leh ee PCB. Guddiga saldhigga Copper wuxuu bedelayaa hiitarka iyo qaybaha kale, hagaajinta caabbinta kulaylka iyo waxqabadka jireed ee alaabta waxayna yareysaa kharashyada wax soo saarka iyo kharashka shaqada.

Waxaad laga yaabaa:

1, sifooyinka codsiga ee aluminium PCB

2, habka daadin Copper ee lakabka sare PCB (PTH)

Baro wax badan oo ku saabsan alaabta YMS