Ceramic PCB imwe uye yakapetwa kaviri mativi ceramics PCB inogadzira Ceramic Substrates| YMS PCB

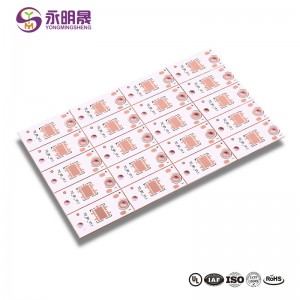

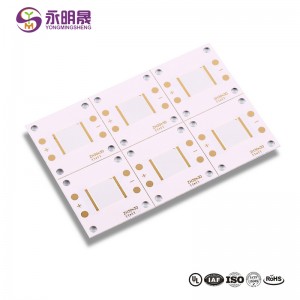

Ceramic PCB: ceramic substrate redunhu bhodhi

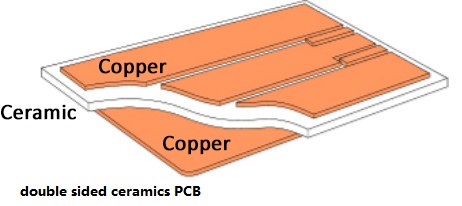

Ceramic Substrate inotsanangura yakasarudzika maitiro bhodhi uko iyo yemhangura aluminium foil yakanamira yakatwasuka kune iyo nzvimbo (yega divi kana maviri maviri) yealumina (Al2O3) kana lightweight aluminium nitride (AlN) ceramic substrate pakupisa. Kana ichienzaniswa neyakajairwa FR-4 kana yakareruka huremu aluminium substrate, iyo yekupedzisira-yakatetepa inoumbwa substrate yakagadzirwa ine yakasarudzika magetsi ekudzivirira, yakakwirira yekupisa conductivity, yakasarudzika yakapfava solderability uye yakakwirira bond stamina, uye zvakare inogona kuvezwa akawanda magiraidhi sePCB, ine fantastic iripo lugging kugona. Inokodzera zvinhu zvine chizvarwa chinodziya chakanyanya (kupenya kwepamusoro LED, simba rezuva), pamwe nemamiriro ayo ekunze ekunze anopikisa zviri nani kune hutsinye hwekunze. Ceramic Circuit Board Technology Introduction

Sei kushandisa ceramics zvinhu kugadzira redunhu mapuranga? Ceramic circuit boards inogadzirwa nemagetsi ceramics uye inogona kuitwa mumhando dzakasiyana. Hunhu hwekupikisa kwepamusoro-tembiricha uye yakakwirira magetsi ekudzivirira eceramic circuit board ndiyo inonyanya kuoneka. Zvakanakira yakaderera dielectric kugara uye dielectric kurasikirwa, yakakwira yekupisa conductivity, yakanaka kugadzikana kwemakemikari, uye yakafanana thermal yekuwedzera coefficient kune zvikamu zvakakoshawo. Kugadzirwa kweceramic redunhu mabhodhi kuchashandisa LAM tekinoroji, inova laser kukurumidza activation metallization tekinoroji. Anoshandiswa mumunda we LED, high-power power semiconductor modules, semiconductor refrigerators, electronic heaters, power control circuits, power hybrid circuits, smart power components, high-frequency switching power supply, solid-state relays, motokari dzemagetsi, kutaurirana, aerospace, uye zvechiuto zvemagetsi zvikamu.

Zvakanakira Ceramic PCB

Kusiyana neyakajairwa FR-4, zvinhu zveceramic zvine kunaka kwepamusoro-frequency kuita uye mashandiro emagetsi, zvine high thermal conductivity, kugadzikana kwekemikari, kugadzikana kwekupisa kwakanyanya, uye zvimwe zvinhu izvo organic substrates hazvina. Icho chitsva chakanakira kurongedza zvinhu zvekugadzirwa kweakakura-akasanganiswa maseketi uye magetsi emagetsi modules.

Mabhenefiti makuru:

Higher thermal conductivity.

Zvimwe zvinofananidza thermal yekuwedzera coefficient.

Yakasimba uye yakaderera kuramba simbi firimu alumina ceramic redunhu bhodhi.

Iyo solderability ye substrate yakanaka, uye tembiricha yekushandisa yakakwira.

Insulation yakanaka.

Low high-frequency loss.

High-density ungano inogoneka.

Iyo haina organic zvinongedzo, inopokana nemwaranzi yecosmic, ine kuvimbika kwakanyanya mumhepo, uye ine hupenyu hurefu hwesevhisi.

Iyo mhangura yemhangura haina oxide layer uye inogona kushandiswa kwenguva yakareba mumhepo inoderedza. Ceramic PCBs inogona kubatsira uye inoshanda kune akadhindwa edunhu mabhodhi mune aya uye mamwe akawanda maindasitiri, zvichienderana nedhizaini yako nekugadzira zvaunoda.

Ceramic PCB imhando yekupisa inoitisa ceramic hupfu uye organic binder, uye kupisa conduction organic ceramic PCB inogadzirirwa pakupisa kwe9-20W/m. Mune mamwe mazwi, ceramic PCB ibhodhi rakadhindwa redunhu rine ceramic base material, iro rinopisa zvakanyanya kupisa zvinhu zvakaita sealuminium, aluminium nitride, pamwe neberyllium oxide, inogona kuita nekukurumidza kufambisa kupisa kure nenzvimbo dzinopisa uye kupera. pamusoro pechiso chose. Chii zvakare, ceramic PCB inogadzirwa neLAM tekinoroji, inova laser inokurumidza activation metallization tekinoroji. Saka ceramic PCB inoshanda zvakasiyana-siyana iyo inogona kutora nzvimbo yese yechinyakare yakadhindwa yedunhu bhodhi ine isinganyanye kuomarara kuvaka nekuita kwakakwidziridzwa.

Kunze kweMCPCB , kana iwe uchida kushandisa PCB mukumanikidza kwakanyanya, kukwirisa kwakanyanya, kukwirisa frequency, tembiricha yakakwira, uye yakavimbika uye diki vhoriyamu zvigadzirwa zvemagetsi, ipapo Ceramic PCB ichave sarudzo yako yakanaka.

Nei Ceramic PCB ine kuita kwakanakisa kudaro? Iwe unogona kuve nekuona mupfupi pane yayo yekutanga chimiro uye ipapo iwe unozonzwisisa.

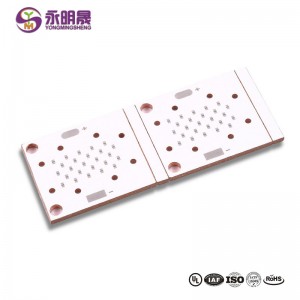

- 96% kana 98% Alumina (Al2O3), Aluminium Nitride (ALN), kana Beryllium Oxide (BeO)

- Maconductor zvinhu: Kune yakaonda, gobvu firimu tekinoroji, ichave sirivheri palladium (AgPd), goridhe pllladium (AuPd); KuDCB (Direct Copper Bonded) ichange iri mhangura chete

- Kushandisa tembiricha: -55~850C

- Thermal conductivity kukosha: 24W~28W/mK (Al2O3); 150W~240W/mK yeALN , 220~250W/mK yeBeO;

- Kunyanya kusimba simba:> 7,000 N/cm2

- Kuputsa Voltage (KV/mm): 15/20/28 ye0.25mm/0.63mm/1.0mm zvichiteerana

- Thermal yekuwedzera conefficient(ppm/K): 7.4 (pasi pe50~200C)

Mhando dzeceramic PCBs

1. High tembiricha zvedongo PCB

2. Low tembiricha zvedongo PCB

3.Gobvu firimu zvedongo PCB

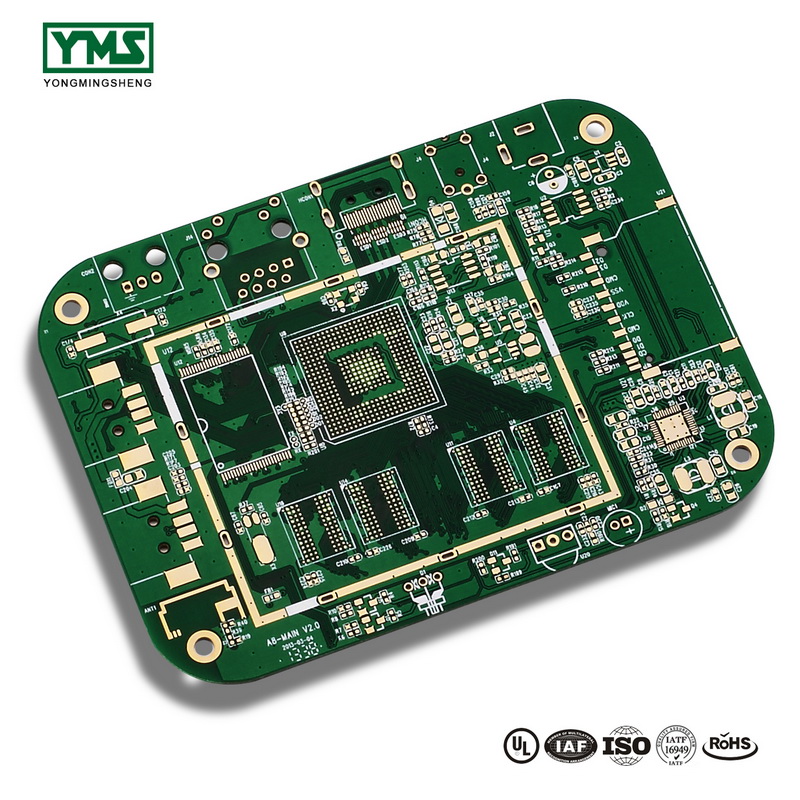

YMS Ceramic PCB kugadzira kugona:

| YMS Ceramic PCB yekugadzira kugona kuongorora | ||

| Feature | kugona | |

| Layer Count | 1-2L | |

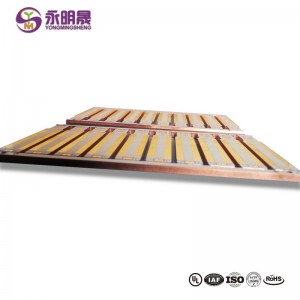

| Zvinhu uye Ukobvu | Al203: 0.15, 0.38,0.5,0.635,1.0,1.5,2.0mm nezvimwe. | |

| CHIVI: 0.25,0.38,0.5,1.0mm nezvimwe. | ||

| AIN: 0.15, 0.25,0.38,0.5, 1.0mm nezvimwe. | ||

| Thermal conductivity | Al203: Min. 24 W/mk kusvika 30W/mk | |

| CHIVI: Min. 85 W/mk kusvika ku100W/mk | ||

| AIN: Min. 150 W/mk kusvika 320 W/mk | ||

| Al2O3 | Al2O3 ine zvirinani chiedza reflectivity - ichiita kuti ikwane kune zvigadzirwa zve LED. | |

| CHIVI | SiN ine CTE yakaderera kwazvo. Yakabatana neiyo yakakwira Rupture Strength inokwanisa kumira kutyisa kwakasimba kwekushisa. | |

| AlN | AlN ine yepamusoro Thermal Conductivity - ichiita kuti ive yakakodzera kune yakanyanya simba maapplication inoda yakanakisa inobvira thermal substrate. | |

| Kukora kweBhodi | 0.25mm-3.0mm | |

| mhangura Ukobvu | 0.5-10OZ | |

| Minimum mutsara Hupamhi uye Nzvimbo | 0.075mm/0.075mm(3mil/3mil) | |

| Specialty | Countersink, Counterbore kuchera.etc. | |

| Min michina Yakaboorwa Saizi | 0.15mm (6mil) | |

| Conductor zvinhu: | Kune tekinoroji yefirimu yakaonda, ichave sirivheri palladium (AgPd), goridhe pllladium (AuPd), Platinamu YeDCB (Yakananga Copper Bonded) ichave yemhangura chete. | |

| Pamusoro Pedza | HASL, Tungamira yemahara HASL, ENIG, Kunyudza Tin, OSP, Kunyudza Sirivheri, Goridhe Munwe, Electroplating Hard Goridhe, Inosarudza OSP, ENEPIG.etc. | |

| Solder Mask | Green, Tsvuku, Yero, Bhuruu, Chena, Dema, Pepuru, Matte Nhema, Matte girini.etc. | |

| polished | Ra <0.1 um | |

| rapped | Ra <0.4 um | |

Dzidza zvakawanda nezve YMS zvigadzirwa

Verenga dzimwe nhau