Edge Plating PCB 10 Layer Board kumucheto plating PCB| YMS PCB

Chii chinonzi PCB Edge Plating?

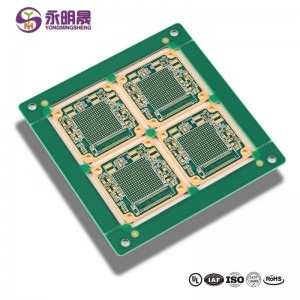

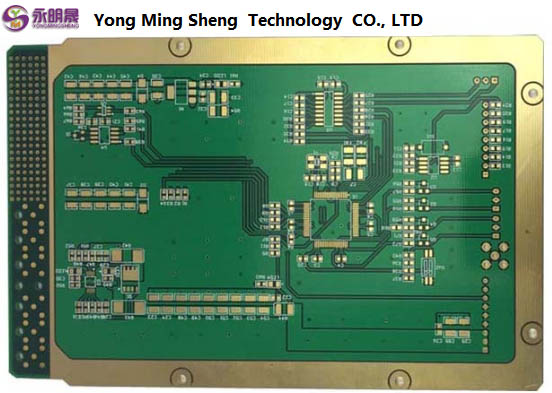

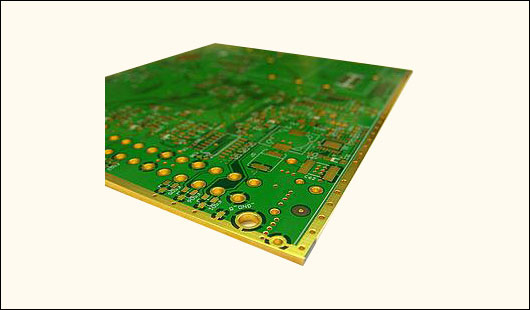

PCB edge plating ndiyo nzira yekubatanidza kumusoro uye pasi pePCB ne electroplating kumativi ekunze ePCB. Iyi nzira zvakare inogona kunzi sideplating, muganho plating, edge metalizing, kana plated contour. Kune zvishandiso zvine mwero kana zvakakwirira zvinodiwa zveEMC, kutendeseka kwechiratidzo, uye kupisa kupisa, kupendeka kwemupendero kune mabhenefiti ari pachena pamutengo usingakodzeri. Kazhinji, ENIG kana nickel-goridhe inokurudzirwa kuti ive nzira yekupedzisa yekupendesa.

EDGE PLATING PCB PROCESS

Yakadhindwa redunhu bhodhi kugadzirwa kwe edge soldering inoda kunyatso batwa uye inotarisana nematambudziko mazhinji akatenderedza magadzirirwo emipendero yakapfava uye kunamatira kwehupenyu hwese kwezvinhu zvakapfekwa.

MCL yakamisa maindasitiri maitiro uye inogadzira kune aya zviyero kuti ive nechokwadi chekuti PCB castellation inonyatso gadzirira nzvimbo dzepamusoro, inoshandisa iyo mhangura yakapfava kuti inonamatira nekukurumidza uye inogadzirisa bhodhi kuti ive nechokwadi chekunamira kwenguva refu kwega rega rega.

By using a controlled process in our circuit board fabrication for edge soldering, we can limit any potential hazard for through-holes and half-holes on the edge. The most significant concern is the creation of burrs, which will lead to the failure of mission-critical parts and can damage your equipment.

APPLICATIONS

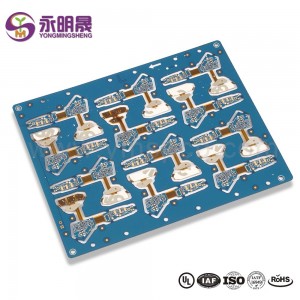

Edge plating wedunhu mabhodhi akajairika mumaindasitiri mazhinji, uye kupendeka kwemupendero chinhu chakajairika. Iwe uchawana PCB kumucheto castellation (kana mupendero plating PCBs) inoshandiswa mune dzakawanda zviitiko, kusanganisira:

Kuvandudza hunyanzvi hwekutakura ikozvino

Edge kubatana uye kudzivirira

Edge solder kuvandudza kugadzirwa

Zvirinani tsigiro yezvekubatanidza semabhodhi anotsvedza mumakesi esimbi

Ndokumbira utarise kuti kupendekera kumucheto pamabhodhi edunhu akadhindwa kuri nyore kuwedzera muzviitiko zvakawanda, asi kunoda hunyanzvi hwekushandisa uye kudzidziswa. Iyo sarudzo yemabhodhi akawanda akasiyana, asi isu tinogara tichikurudzira kutora rudzi urwu rwekukumbira kumugadziri, seMCL, ane mukurumbira wakagadzwa wedunhu bhodhi castellation.

Tichakwanisa kuita macheki einjiniya akakodzera kuchengetedza zvese zvakachengeteka. Semuyenzaniso, redunhu bhodhi castellation haifanire kuita kuti ndege dzemagetsi dzemukati dziuye kumucheto kwebhodhi, nekuti inogona kupfupisa kumucheto plating. Paunenge uchifamba, gara uchifunga nezve gap. Kana isu tichiita redunhu bhodhi kugadzirwa kwemupendero solder, isu tinogara tichiita shuwa kuti pane gaka pamberi pemupendero plating. Edge plating inobatsira kugadzira kubatana kwakasimba kwePCB uye inogona kuderedza mukana wekutadza kwechishandiso. Naizvozvo, edge plating inoshandiswa zvakanyanya mumashandisirwo apo zvinongedzo zvinoda kutsigirwa zvirinani uye inova tsika yakajairika mukugadzira pcb yekugadzira . YMS inopa hunyanzvi midziyo uye nyanzvi mainjiniya kuita padivi plating maitiro. Ndokumbira utumire E-mail kwatiri kana kubata masevhisi edu epamhepo kuti uwane rumwe ruzivo nezve edge plating maitiro uye dhizaini paramita.

Kuganhurirwa

Nekuti vanogadzira vanoda kubata mabhodhi edunhu mukati meiyo dhizaini yekugadzira muPCb prototype, havagone kupeta mupendero wakazara. Naizvozvo, pane mamwe mapeji anodiwa kuti uise rout tabo. Inoda kufambisa iyo yedunhu bhodhi chimiro panzvimbo paunenge uchigadzira mapuranga edunhu ane mupendero plating , uye kumucheto plating inodiwa usati watanga nzira yekupfuura-gomba plating, iyo inobvisa v-cut scoring paPCB inoda kupinza mupendero. .

Iko kumucheto plating PCB muYMS

Neanopfuura makore gumi semutungamiri weindasitiri, YMS ine yakawanda yekugadzira ruzivo rwePCB edge plating, uye isu tinokwanisa kudzora mhando yepamusoro yekuisa pamupendero pasina maburrs. Nekuti kugutsikana kwevatengi ndicho chinangwa chedu, tichaedza nepatinogona napo kugadzira bhodhi rako nemhando yepamusoro kuti rizadzise zvaunoda uye takazvipira kutevedzera zvakaomesesa zviyero muPCB yekugadzira nekuunganidza.

YMS, mubatsiri weanjiniya wemagetsi, ari kukupa kugadzirwa kwePCB kwakaderera nemhando yepamusoro.

Unogona Kuda:

1, Maitiro ekuita yakakwira frequency PCB

2, Ruzivo rwakajairika rweyakakwira frequency PCB wiring (1)

3, Ruzivo rwakajairika rweyakakwira frequency PCB wiring (2)

Vhidhiyo

Dzidza zvakawanda nezve YMS zvigadzirwa

Chii chinonzi edge plating muPCB?

Iwe unogona kunge wakanzwa pfungwa iyi inonzi "kumucheto plating" kana "castelation," inova iyo yemhangura yemhangura inomhanya kubva kumusoro ichienda pasi penzvimbo yePCB, uye inomhanya ichitevedza imwe yemapendero ekutenderera. PCB edge castellation inovimbisa kubatana kwakasimba kuburikidza nebhodhi uye inodzikamisa mukana wekutadza kwemidziyo, kunyanya mukudzora dziviriro yediki fomu factor board uye sub-motherboards.

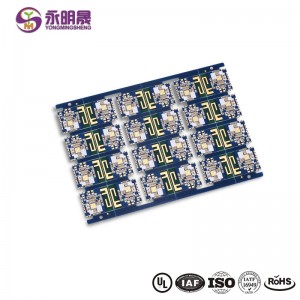

Chii chinonzi copper plating muPCB?

Copper plating inonzi electro-chemical process, umo chidimbu chemhangura chinoiswa panzvimbo yesimbi yechinhu chakasimba kuburikidza nekushandiswa kwemagetsi.

Copper plating inzira yakakosha nekuti:

Inopa kuchengetedzwa kwakakosha kwekuora.

Inovandudza kupfeka kusagadzikana kwepamusoro.

Iyo ine yakanakisa kunamatira kune akawanda base simbi, inovandudza ductility yezvigadzirwa zvakavharwa.

Iyo ine yakanakisa kupisa conductivity uye yemagetsi conductivity, ichiita kuti zvigadzirwa zvakapfava zvienderane nemashandisirwo einjiniya, senge akadhindwa edunhu mabhodhi (PCB).