Flex rigid Board semi flex PCB Black Soldermask| YMSPCB

What is Semi-Flex PCB?

Najbolj tradicionalen postopek izdelave polfleksnih PCB je prevzem upogibnih materialov FR-4 in izdelava PCB po tradicionalnem postopku izdelave togih PCB, nato pa uporaba tehnologije globokega rezkanja tanjša površine, ki jih je treba upogniti, tako da določeno stopnjo fleksibilnosti, da ustreza zahtevam sklopnega upogibnega priključka.

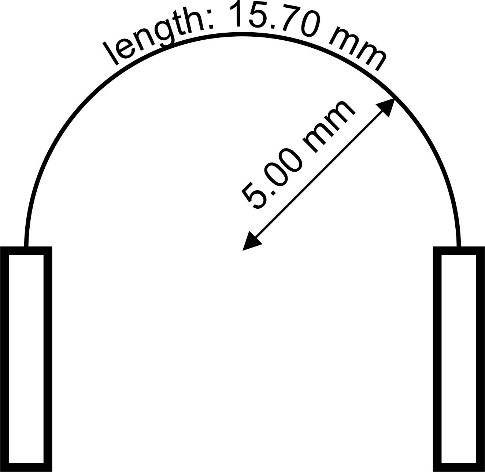

Kalkulator dolžine SEMI-FLEX: (2 x Π x polmer upogiba) x (kot upogiba / 360 °)

Na primer, petkratno upogibanje pod kotom 180 stopinj s polmerom 5 mm zahteva najmanjšo dolžino polfleksnega dela 15,7 mm

Zmogljivosti za Semi-Flex PCB manufacturing capa:

| Pregled proizvodnih zmožnosti YMS Semi-Flex PCB | ||

| Značilnost | zmogljivosti | |

| Število slojev | 2-20L , z 1 - 2 prevodnimi sloji v fleksibilnem odseku | |

| Debelina togega upogiba | 0,5 mm-5,0 mm | |

| Debelina PCB v fleksibilnem odseku | 0,15-0,8 mm ± 0,05 mm | |

| debelina bakra | 1 / 4OZ-10OZ | |

| Najmanjša širina črte in presledek | 0,05 mm / 0,05 mm (2 mil / 2 mil) | |

| Ojačevalci | Nerjaveče jeklo, PI, FR4, aluminij itd. | |

| material | FR4, RA baker, HTE baker, lepilo, Bondply , prevleka, fleksibilna spajkalna maska | |

| Min. Mehanska vrtana velikost | 0,15 mm (6 mil) | |

| Najmanjša velikost luknjic laserja: | 0,075 mm (3 mil) | |

| Površinska obdelava | Primerni zaključki površin za mikrovalovne / RF PCB: brezelektrični nikelj, potopno zlato, ENEPIG, brez svinca HASL, potopno srebro itd. | |

| Maska za spajkanje | Zelena, rdeča, rumena, modra, bela, črna, vijolična, mat črna, mat zelena itd. | |

| Covrelay (Flex del) | Rumena prevleka, bela prevleka, črna prevleka |

|

Preberite več o izdelkih YMS

Preberite več novic

What is a rigid flex board?

The rigid-flex board is a flexible circuit board(FPC) and a rigid circuit board (PCB), which are combined together according to the relevant process requirements through pressing and other processes in the PCB proofing to form a circuit board with FPC characteristics and PCB characteristics.

What is difference between rigid and flexible boards?

As the names suggest, a rigid PCB is a circuit board built on a rigid base layer that cannot bend, while a flexible PCB, also called a flex circuit, is built on a flexible base capable of bending, twisting and folding.

Where are rigid flex PCBs used?

You’ll find them in commercial, industrial and military applications. From digital cameras to cell phones to smart devices, they serve them all. Especially in the medical industry for developing pacemakers for their weight reduction, space, and flexible capabilities.