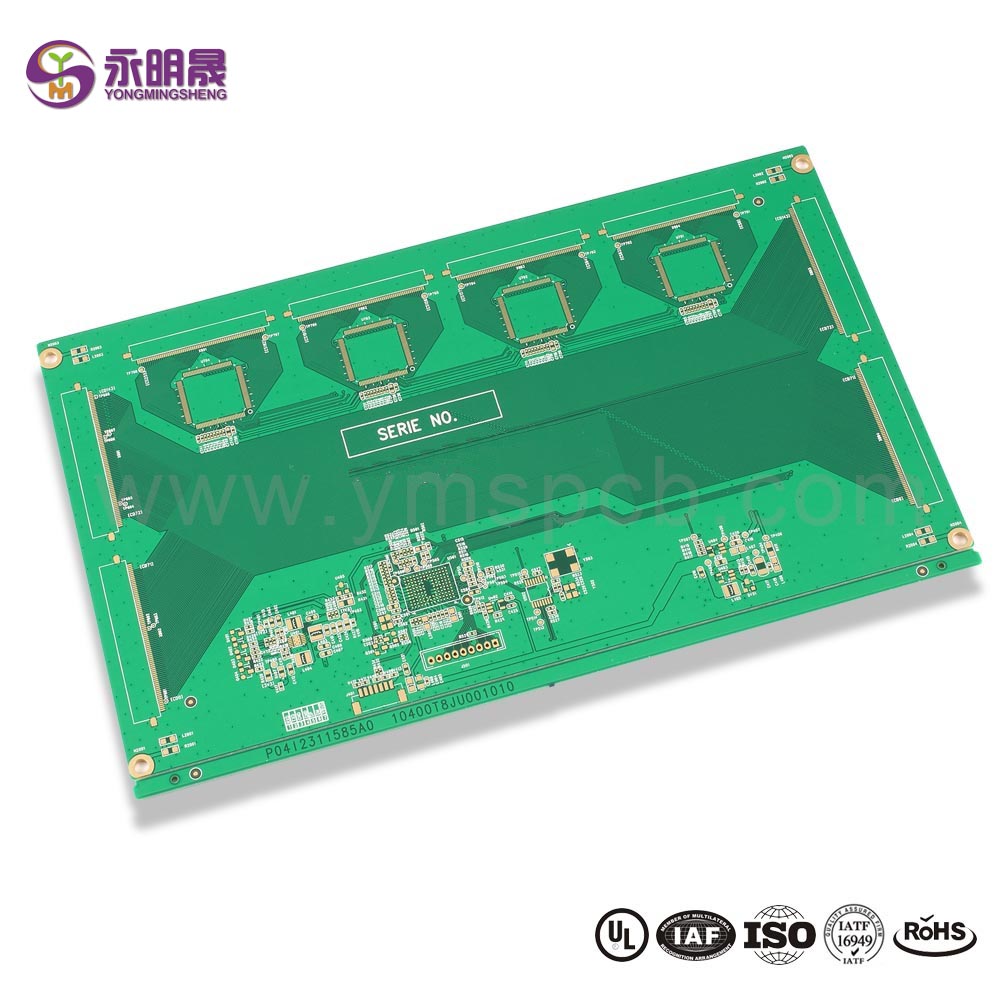

Rigid flex pcb design HDI staggered vias and stacked vias Stiffener| YMSPCB

Rigid-Flex product types include:

- Type 1: Single sided flexible material with or without shield(s) or stiffener (one conductive layer).

- Type 2: Double sided flexible material with or without shield(s) or stiffener (two conductor layers) with plated through holes.

- Type 3: Multilayer flexible material with or without shield(s) or stiffener (more than two conductor layers) with plated through holes and HDI.

- Type 4: Multilayer rigid and flexible material combinations (more than two conductor layers) with plated through holes and HDI.

YMS Rigid Flex PCB manufacturing capabilities:

| YMS Rigid Flex PCB manufacturing capabilities overview | ||

| Feature | capabilities | |

| Layer Count | 2-20L | |

| Rigid-Flex Thickness | 0.3mm-5.0mm | |

| PCB thickness in flex section | 0.08-0.8mm | |

| copper Thickness | 1/4OZ-10OZ | |

| Minimum line Width and Space | 0.05mm/0.05mm(2mil/2mil) | |

| Stiffeners | Stainless steel,PI, FR4 ,Aluminum etc. | |

| Material | Polyimide Flex+FR4,RA copper, HTE copper, polyimide, adhesive,Bondply | |

| Min mechanical Drilled Size | 0.15mm(6mil) | |

| Min laser Holes Size: | 0.075mm(3mil) | |

| Surface Finish | Suitable Microwave/RF PCB urface finishes: Electroless Nickel, Immersion Gold, ENEPIG, Lead free HASL,Immersion Silver.etc. | |

| Solder Mask | Green, Red, Yellow, Blue, White, Black, Purple, Matte Black, Matte green.etc. | |

| Covrelay (Flex Part) | Yellow Coverlay, WhiteCoverlay,Black Coverlay | |

Learn more about YMS products

Read more news

What is flexible and rigid flex PCB

As the names suggest, a rigid PCB is a circuit board built on a rigid base layer that cannot bend, while a flexible PCB, also called a flex circuit, is built on a flexible base capable of bending, twisting and folding.

Where are rigid flex PCBs used?

Medical;Military;Aerospace;Telecommunication

Write your message here and send it to us