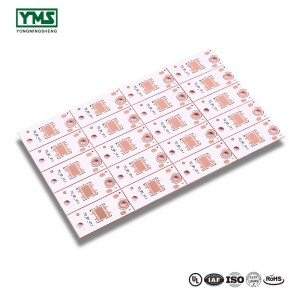

Quots for China Heavy Copper Multilayer Heater Control Power PCB Board

The corporation upholds the philosophy of “Be No.1 in high quality, be rooted on credit rating and trustworthiness for growth”, will continue to serve outdated and new consumers from home and overseas whole-heatedly for Quots for China Heavy Copper Multilayer Heater Control Power PCB Board, Our merchandise are widely recognized and trusted by users and can meet up with continuously changing economic and social needs.

The corporation upholds the philosophy of “Be No.1 in high quality, be rooted on credit rating and trustworthiness for growth”, will continue to serve outdated and new consumers from home and overseas whole-heatedly for China PCB, Pcb Board, We have won a good reputation among overseas and domestic clients. Adhering to the management tenet of “credit oriented, customer first, high efficiency and mature services”, we warmly welcome friends from all walks of life to cooperate with us.

Heavy Copper PCB are printed circuit boards with 3 or more ounces of finished copper in the inner and/or outer layers.

While there is no standard definition of Heavy Copper, it is generally accepted that if 3 ounces (oz) of copper or more is used on the internal and external layers of a printed circuit board, it is called a heavy copper PCB. Any circuit with a copper thickness of more than 4 oz per square foot (ft2) is also categorized as a heavy copper PCB.

The construction of a heavy copper circuit endows a board with benefits such as:

- Increased endurance to thermal strains.

- Increased current carrying capacity.

- Increased mechanical strength at connector sites and in PTH holes.

- Use of exotic materials to their full potential without circuit failure.

- Reduced product size by incorporating multiple copper weights on the same layer of circuitry .

- Heavy copper plated vias carry higher current through the board and help to transfer heat to an external heatsink.

Thick copper plate basic production process:

A、The inner core plate is obtained by cutting materials, and the inner circuit is made on each inner core plate respectively through the processing of inner graph and etching. A number of copper pads are interleaved on the edge of the plate in the open area of each inner core plate to make each inner core plate.

B、The inner layer and outer layer of copper foil are pressed together by semi-curing sheet to make multi-layer production plate.

C、According to the existing technology, the thick copper plate is prepared by the post-treatment of the multilayer production plate.

You May Like:

1、What are the precautions for heavy copper PCB wiring

2、What are the specifications of heavy copper PCB

3、What are the heavy copper PCB materials

Board2.jpg)

Board2-300x300.jpg)