Quality Inspection for Sensor Printed Circuit Board - Copper Base High Power (Metal core) Board | YMS PCB – Yongmingsheng

Quality Inspection for Sensor Printed Circuit Board - Copper Base High Power (Metal core) Board | YMS PCB – Yongmingsheng Detail:

The main reasons for using copper base boards

1. Good heat dissipation: At present, many 2 layer board and multilayer boards have the advantage of high density and high power, but the heat emission is difficult to be. Normal PCB base material such as FR4, CEM3 is a poor conductor of heat, insulation is between layers, and heat emission cannot go out. Local heating of electronic equipment cannot be eliminated will result in high-temperature failure of electronic components. But the good heat dissipation performance of metal core PCB can solve this heat dissipation problem.

2. Dimensional stability: Metal core PCB is obviously much more stable in size than printed boards of insulating materials. Aluminum base board and aluminum sandwich board is heating from 30℃ to 140~150℃, its size changes of 2.5~3.0%.

3. Other cause: Copper base board has shielding effect and replaces brittle ceramic substrate, so it can rest assured to use surface mounting technology to reduce the real effective area of PCB. Copper base board replaces the radiator and other components, improve the heat resistance and physical performance of products and it reduces production costs and labor costs.

1. Good heat dissipation: At present, many 2 layer board and multilayer boards have the advantage of high density and high power, but the heat emission is difficult to be. Normal PCB base material such as FR4, CEM3 is a poor conductor of heat, insulation is between layers, and heat emission cannot go out. Local heating of electronic equipment cannot be eliminated will result in high-temperature failure of electronic components. But the good heat dissipation performance of metal core PCB can solve this heat dissipation problem.

2. Dimensional stability: Metal core PCB is obviously much more stable in size than printed boards of insulating materials. Aluminum base board and aluminum sandwich board is heating from 30℃ to 140~150℃, its size changes of 2.5~3.0%.

3. Other cause: Copper base board has shielding effect and replaces brittle ceramic substrate, so it can rest assured to use surface mounting technology to reduce the real effective area of PCB. Copper base board replaces the radiator and other components, improve the heat resistance and physical performance of products and it reduces production costs and labor costs.

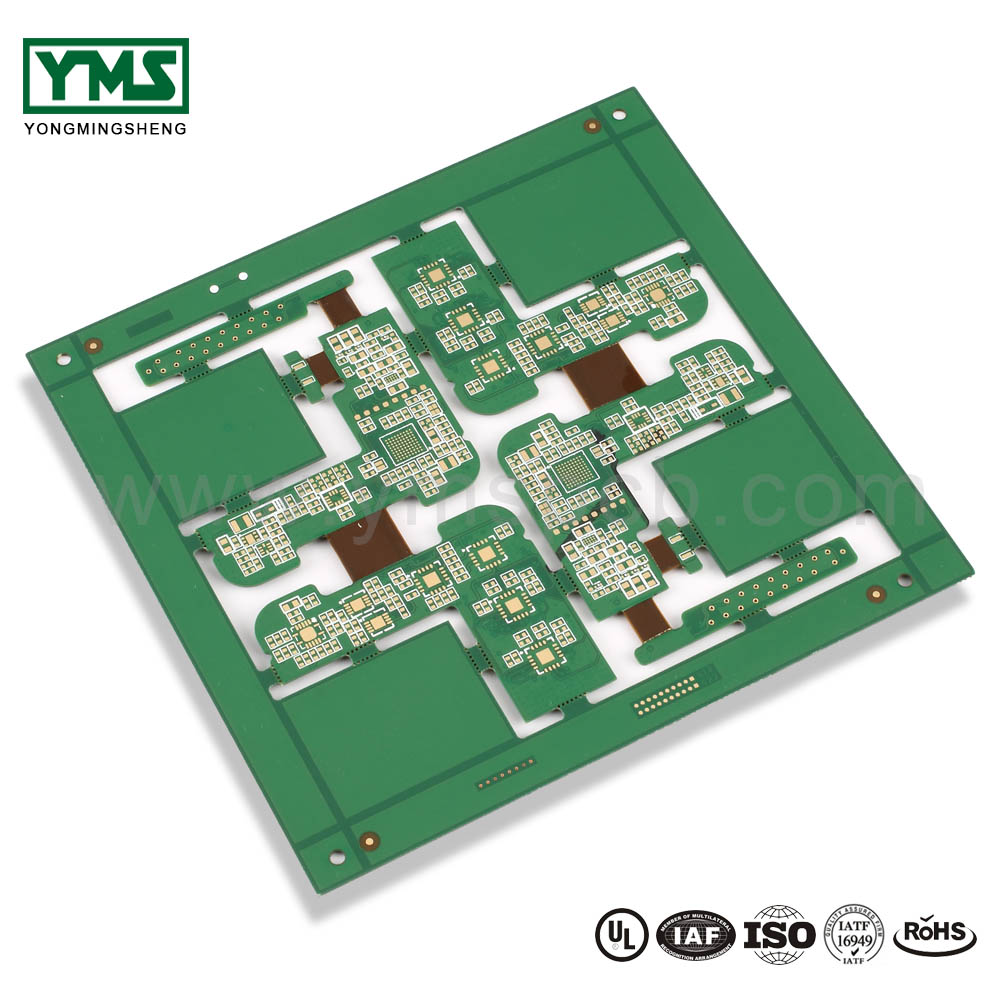

Product detail pictures:

Related Product Guide:

High Density Interconnect(HDI) PCBs Market Report Forecast by Industry Outlook, Capital Investment, Opportunities & Trends 2024 | Copper Base Board

High-Density Interconnect (HDI) PCB Market- Industry Analysis, Size, Share, Growth, Trends and Forecast till 2025 | Rigid-Flexible Pcb

Generally customer-oriented, and it's our ultimate goal for being not only the most trusted, trustable and honest provider, but also the partner for our customers for Quality Inspection for Sensor Printed Circuit Board - Copper Base High Power (Metal core) Board | YMS PCB – Yongmingsheng , The product will supply to all over the world, such as: Iraq, Borussia Dortmund, London, If you are for any reason unsure which product to select, do not hesitate to contact us and we will be delighted to advise and assist you. This way we will be providing you with all the knowledge needed to make the best choice. Our company strictly follows "Survive by good quality, Develop by keeping good credit. " operation policy. Welcome all the clients old and new to visit our company and talk about the business. We are looking for more and more customers to create the glorious future.

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!

Write your message here and send it to us

Board2.jpg)