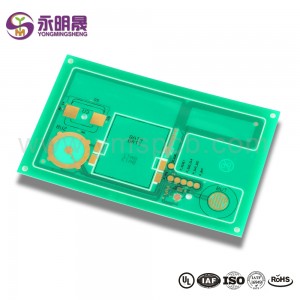

Professional Design Heavy Copper Double Sided Pcb Circuit Board

We stick to the principle of “quality first, service first, continuous improvement and innovation to meet the customers” for the management and “zero defect, zero complaints” as the quality objective. To perfect our service, we provide the products with the good quality at the reasonable price for Professional Design Heavy Copper Double Sided Pcb Circuit Board, Our goods are widely used in many industrial fields. Our Corporation Services Division in good faith for that purpose of the quality of survival. All for customer company.

We stick to the principle of “quality first, service first, continuous improvement and innovation to meet the customers” for the management and “zero defect, zero complaints” as the quality objective. To perfect our service, we provide the products with the good quality at the reasonable price for Double Sided Pcb, Pcb, Pcb Circuit Board, Welcome any of your inquiries and concerns for our products. We look forward to establishing a long-term business relationship with you in the near future. Contact us today. We have been the first business partner in your case!

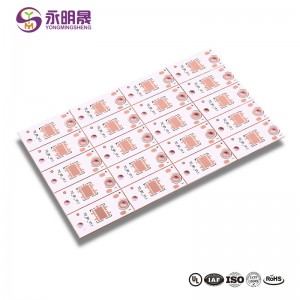

Thick copper plate basic production process:

A、The inner core plate is obtained by cutting materials, and the inner circuit is made on each inner core plate respectively through the processing of inner graph and etching. A number of copper pads are interleaved on the edge of the plate in the open area of each inner core plate to make each inner core plate.

B、The inner layer and outer layer of copper foil are pressed together by semi-curing sheet to make multi-layer production plate.

C、According to the existing technology, the thick copper plate is prepared by the post-treatment of the multilayer production plate.

You May Like:

1、What are the factors that affect the price of heavy copper pcb?

2、What is the manufacturing and packaging process of heavy copper pcb?

3、Introduction of the principle and function of heavy copper pcb

Board5.jpg)

Board5-300x300.jpg)