OEM/ODM Factory Ultra-Thin Single Side Pcb - Cheapest Price Assembly Odm Humidifier Electronic Pcb Printed Circuit Board – Yongmingsheng

OEM/ODM Factory Ultra-Thin Single Side Pcb - Cheapest Price Assembly Odm Humidifier Electronic Pcb Printed Circuit Board – Yongmingsheng Detail:

All we do is usually linked with our tenet ” Shopper first, Rely on very first, devoting around the food packaging and environmental safety for Cheapest Price Assembly Odm Humidifier Electronic Pcb Printed Circuit Board, Each of the time, we’ve got been paying notice on all particulars to insure each item happy by our consumers.

All we do is usually linked with our tenet ” Shopper first, Rely on very first, devoting around the food packaging and environmental safety for Printed Circuit Board, For many years, we now have adhered to the principle of customer oriented, quality based, excellence pursuing, mutual benefit sharing. We hope, with great sincerity and good will, to have the honor to help with your further market.

8 Layer 2 Step HDI Board

HDI Board production process:

At present, HDI board interconnection between layer and layer is mainly the following design: Staggered holes interconnection, Cross-layer interconnection, ladder interconnection and superposition holes interconnection. Among them, the superposition holes interconnection occupy the least space. There is a research suggests that reducing the number of through holes and increasing the number of blind holes can effectively improve the wiring density. And in the superposition interconnection, the methods of electroplating and resin plug are mainly used, especially the electroplating hole filling method which has more obvious advantages like high reliability and good conduction performance. Therefore, superposition interconnection is the most widely used design method for blind holes design. The process of stacking between layers is as follows: first blind hole is made, then second blind hole is made after lamination, then multi-blind hole is made according to this method, and the interconnection between layers is realized by electroplating hole filling method.

On the whole, the production process of HDI plate is complex, which needs to be completed after many times of production for a long time. It’s not only high requirements for the accuracy and shrinkage control of each layer, but also high standards in materials, equipment, environment and technical personnel.

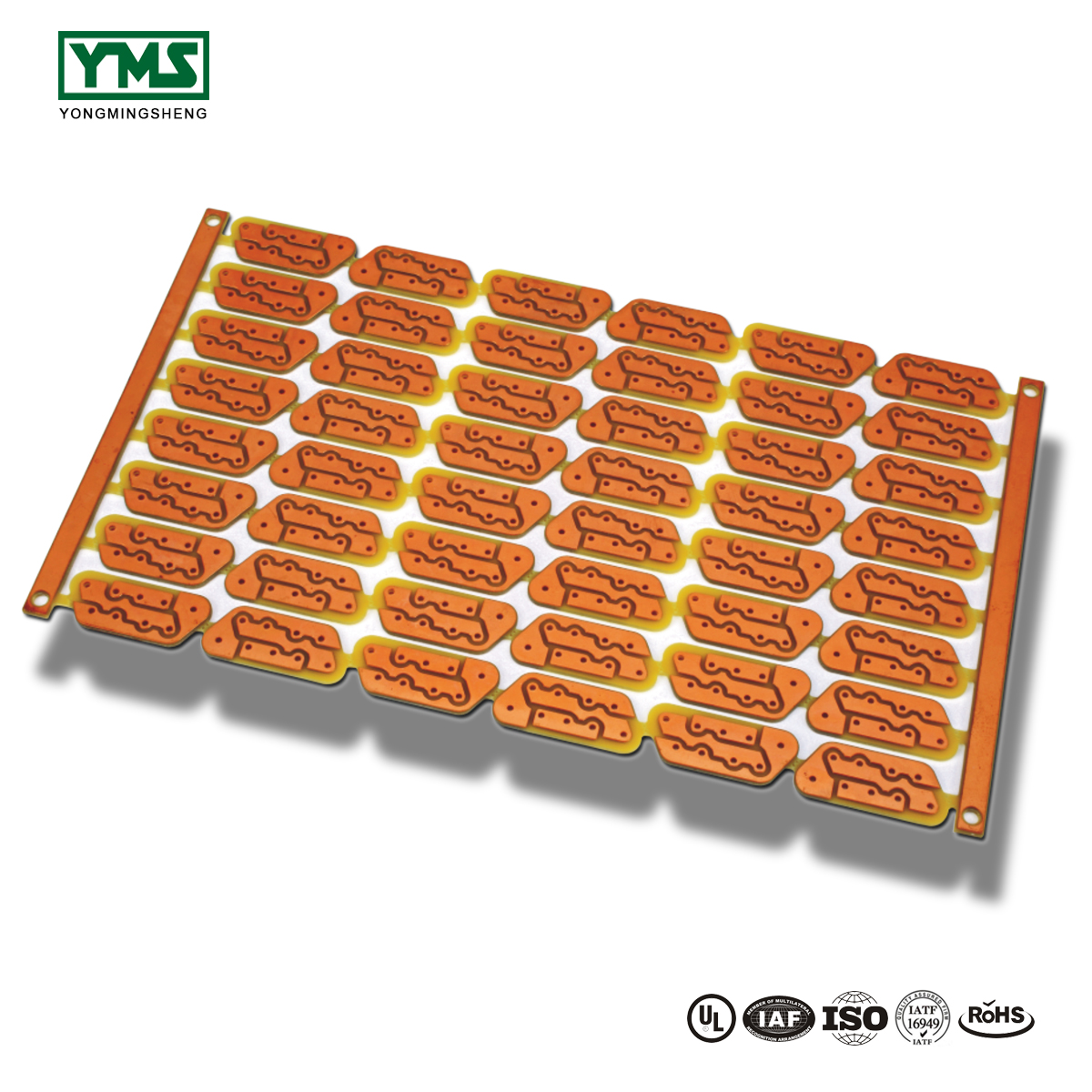

Product detail pictures:

Related Product Guide:

PCB & PCBA Market Outlook by Responsible Drivers, Restraints, Demand & Forecasts by 2024 | Rigid-Flexible Pcb

HDI Market Report – A Complete Overview of Market Segments and the Regional Outlook of HDI Industry | Copper Base Board

We are convinced that with joint efforts, the business between us will bring us mutual benefits. We can assure you product quality and competitive price for OEM/ODM Factory Ultra-Thin Single Side Pcb - Cheapest Price Assembly Odm Humidifier Electronic Pcb Printed Circuit Board – Yongmingsheng , The product will supply to all over the world, such as: Jakarta, luzern, Slovenia, We now have established long-term, stable and good business relationships with many manufacturers and wholesalers around the world. Currently, we've been looking forward to even greater cooperation with overseas customers based on mutual benefits. You should feel free to contact us for more details.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.