OEM Supply Ultra-Thin Led Flexible Pcb - Manufacturing Companies for Industrial Metal Detector Pcb Electronic Circuit Board – Yongmingsheng

OEM Supply Ultra-Thin Led Flexible Pcb - Manufacturing Companies for Industrial Metal Detector Pcb Electronic Circuit Board – Yongmingsheng Detail:

With our loaded practical experience and thoughtful solutions, we now have been identified for a trusted provider for numerous intercontinental consumers for Manufacturing Companies for Industrial Metal Detector Pcb Electronic Circuit Board, We welcome shoppers, business enterprise associations and buddies from all areas from the environment to speak to us and seek out cooperation for mutual gains.

With our loaded practical experience and thoughtful solutions, we now have been identified for a trusted provider for numerous intercontinental consumers for 94v0 Circuit Board, Metal Detector Circuit Board, Metal Detector Pcb, Our goods have been obtained more and more recognition from foreign clients, and established long term and cooperative relationship with them. We`ll offer the best service for every customer and sincerely welcome friends to work with us and establish the mutual benefit together.

The main reasons for using copper base boards

1. Good heat dissipation:

At present, many 2 layer board and multilayer boards have the advantage of high density and high power, but the heat emission is difficult to be. Normal PCB base material such as FR4, CEM3 is a poor conductor of heat, insulation is between layers, and heat emission cannot go out. Local heating of electronic equipment cannot be eliminated will result in high-temperature failure of electronic components. But the good heat dissipation performance of metal core PCB can solve this heat dissipation problem.

2. Dimensional stability:

Metal core PCB is obviously much more stable in size than printed boards of insulating materials. Aluminum base board and aluminum sandwich board is heating from 30℃ to 140~150℃, its size changes of 2.5~3.0%.

3. Other cause:

Copper base board has shielding effect and replaces brittle ceramic substrate, so it can rest assured to use surface mounting technology to reduce the real effective area of PCB. Copper base board replaces the radiator and other components, improve the heat resistance and physical performance of products and it reduces production costs and labor costs.

You May Like:

1、Application characteristics of aluminum PCB

2、Copper plating process of PCB outer layer (PTH)

3、Copper clad plate and aluminum substrate four major differences

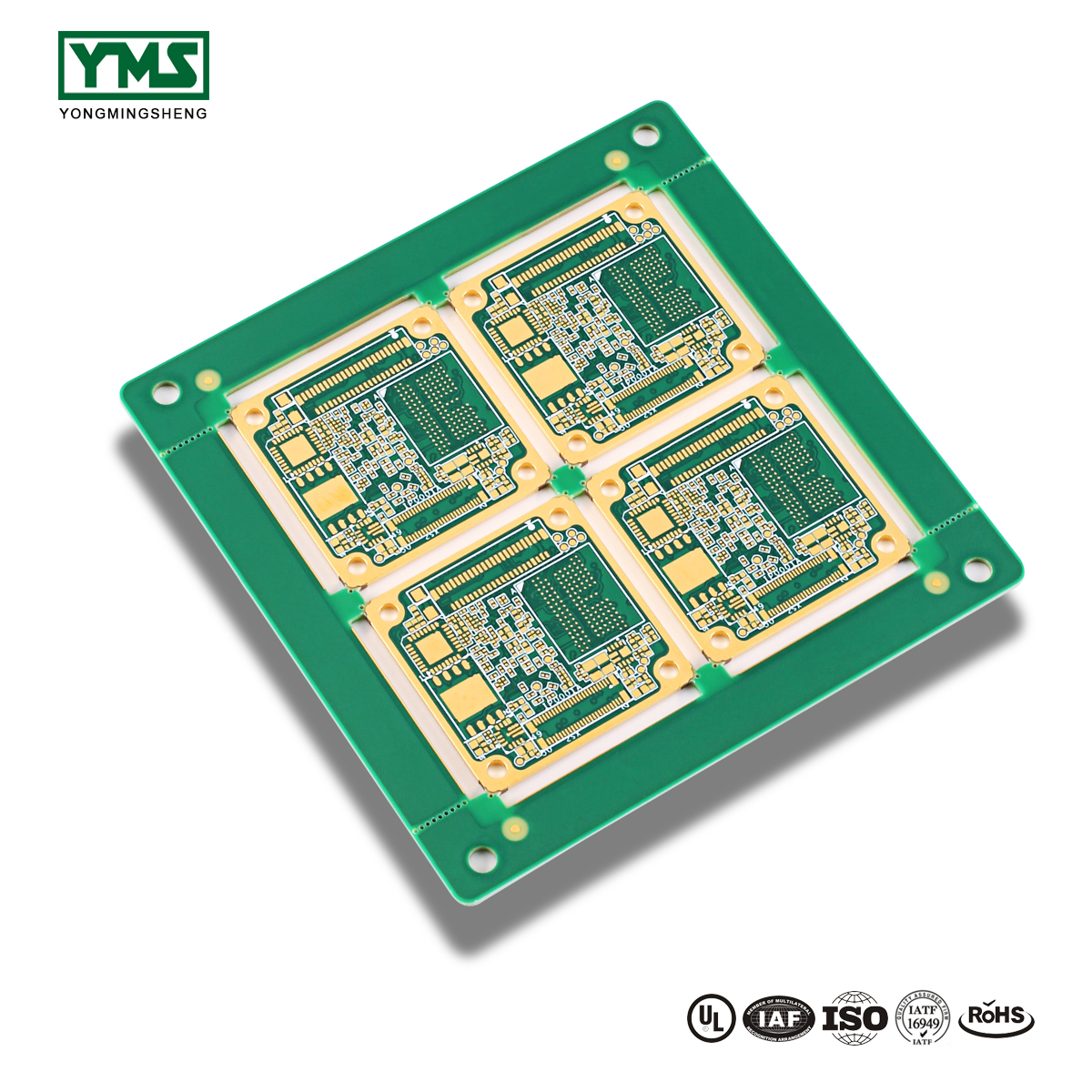

Product detail pictures:

Related Product Guide:

PCB & PCBA Market Outlook by Responsible Drivers, Restraints, Demand & Forecasts by 2024 | Rigid-Flexible Pcb

Global Laser Direct Imaging (LDI) System Market Insights 2019-2026: Top Manufacturer Orbotech, ORC Manufacturing, Fuji Film, SCREEN Holdings | Hdi Pcb

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" as well as the theory of "quality the basic, believe in the 1st and management the advanced" for OEM Supply Ultra-Thin Led Flexible Pcb - Manufacturing Companies for Industrial Metal Detector Pcb Electronic Circuit Board – Yongmingsheng , The product will supply to all over the world, such as: Indonesia, United States, Ecuador, We always insist on the principle of "Quality and service are the life of the product". Till now, our products have been exported to more than 20 countries under our strict quality control and high level service.

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.

Board2.jpg)