OEM Manufacturer Ultra-Thin Lcd Pcb – Copper Base High Power (Metal core) Board | YMS PCB – Yongmingsheng

OEM Manufacturer Ultra-Thin Lcd Pcb – Copper Base High Power (Metal core) Board | YMS PCB – Yongmingsheng Detail:

The main reasons for using copper base boards

1. Good heat dissipation: At present, many 2 layer board and multilayer boards have the advantage of high density and high power, but the heat emission is difficult to be. Normal PCB base material such as FR4, CEM3 is a poor conductor of heat, insulation is between layers, and heat emission cannot go out. Local heating of electronic equipment cannot be eliminated will result in high-temperature failure of electronic components. But the good heat dissipation performance of metal core PCB can solve this heat dissipation problem.

2. Dimensional stability: Metal core PCB is obviously much more stable in size than printed boards of insulating materials. Aluminum base board and aluminum sandwich board is heating from 30℃ to 140~150℃, its size changes of 2.5~3.0%.

3. Other cause: Copper base board has shielding effect and replaces brittle ceramic substrate, so it can rest assured to use surface mounting technology to reduce the real effective area of PCB. Copper base board replaces the radiator and other components, improve the heat resistance and physical performance of products and it reduces production costs and labor costs.

1. Good heat dissipation: At present, many 2 layer board and multilayer boards have the advantage of high density and high power, but the heat emission is difficult to be. Normal PCB base material such as FR4, CEM3 is a poor conductor of heat, insulation is between layers, and heat emission cannot go out. Local heating of electronic equipment cannot be eliminated will result in high-temperature failure of electronic components. But the good heat dissipation performance of metal core PCB can solve this heat dissipation problem.

2. Dimensional stability: Metal core PCB is obviously much more stable in size than printed boards of insulating materials. Aluminum base board and aluminum sandwich board is heating from 30℃ to 140~150℃, its size changes of 2.5~3.0%.

3. Other cause: Copper base board has shielding effect and replaces brittle ceramic substrate, so it can rest assured to use surface mounting technology to reduce the real effective area of PCB. Copper base board replaces the radiator and other components, improve the heat resistance and physical performance of products and it reduces production costs and labor costs.

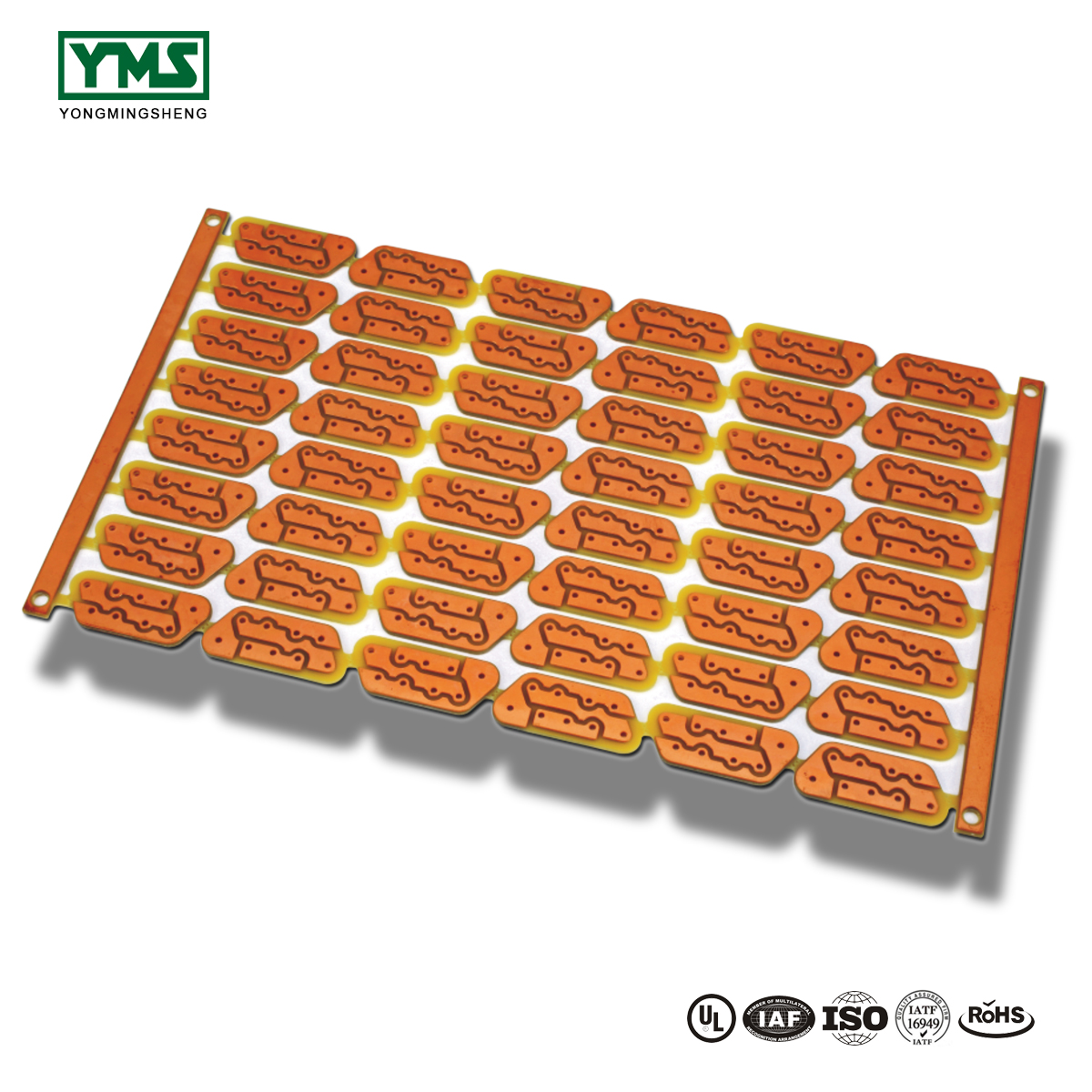

Product detail pictures:

Related Product Guide:

High Density Interconnect(HDI) PCBs Market Report Forecast by Industry Outlook, Capital Investment, Opportunities & Trends 2024 | Copper Base Board

General Micro Systems Launches Apex, the Highest Performance Upgradeable Secure Server under ITAR Control | Rigid-Flexible Pcb

We pursue the management tenet of "Quality is remarkable, Company is supreme, Name is first", and will sincerely create and share success with all clientele for OEM Manufacturer Ultra-Thin Lcd Pcb – Copper Base High Power (Metal core) Board | YMS PCB – Yongmingsheng , The product will supply to all over the world, such as: moldova, Singapore, kazan, Till now, the items list has been updated regularly and attracted clients from around the globe. Comprehensive facts is often obtained in our web-site and you'll be served with premium quality consultant service by our after-sale group. They are likely to help you get thorough acknowledge about our goods and make a satisfied negotiation. Company go to to our factory in Brazil is also welcome at any time. Hope to obtain your inquiries for any pleased co-operation.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!

Write your message here and send it to us

Board2.jpg)