OEM Manufacturer Solder Mask Pcb - Reasonable price Pcb Through Hole Machine,Metal Copper Plating Machine,Pcb Making Machine – Yongmingsheng

OEM Manufacturer Solder Mask Pcb - Reasonable price Pcb Through Hole Machine,Metal Copper Plating Machine,Pcb Making Machine – Yongmingsheng Detail:

Bear “Customer very first, Quality first” in mind, we work closely with our customers and supply them with efficient and professional services for Reasonable price Pcb Through Hole Machine,Metal Copper Plating Machine,Pcb Making Machine, Our group members are goal to provides merchandise with significant performance cost ratio to our consumers, as well as target for all of us is usually to satisfy our consumers from all around the environment.

Bear “Customer very first, Quality first” in mind, we work closely with our customers and supply them with efficient and professional services for Pcb Plating Copper, Pcb Plating Holes Machine, Pcb Through Hole Machine, For many years, we have now adhered to the principle of customer oriented, quality based, excellence pursuing, mutual benefit sharing. We hope, with great sincerity and good will, to have the honor to help with your further market.

The main reasons for using copper base boards

1. Good heat dissipation:

At present, many 2 layer board and multilayer boards have the advantage of high density and high power, but the heat emission is difficult to be. Normal PCB base material such as FR4, CEM3 is a poor conductor of heat, insulation is between layers, and heat emission cannot go out. Local heating of electronic equipment cannot be eliminated will result in high-temperature failure of electronic components. But the good heat dissipation performance of metal core PCB can solve this heat dissipation problem.

2. Dimensional stability:

Metal core PCB is obviously much more stable in size than printed boards of insulating materials. Aluminum base board and aluminum sandwich board is heating from 30℃ to 140~150℃, its size changes of 2.5~3.0%.

3. Other cause:

Copper base board has shielding effect and replaces brittle ceramic substrate, so it can rest assured to use surface mounting technology to reduce the real effective area of PCB. Copper base board replaces the radiator and other components, improve the heat resistance and physical performance of products and it reduces production costs and labor costs.

You May Like:

1、Application characteristics of aluminum PCB

2、Copper plating process of PCB outer layer (PTH)

3、Copper clad plate and aluminum substrate four major differences

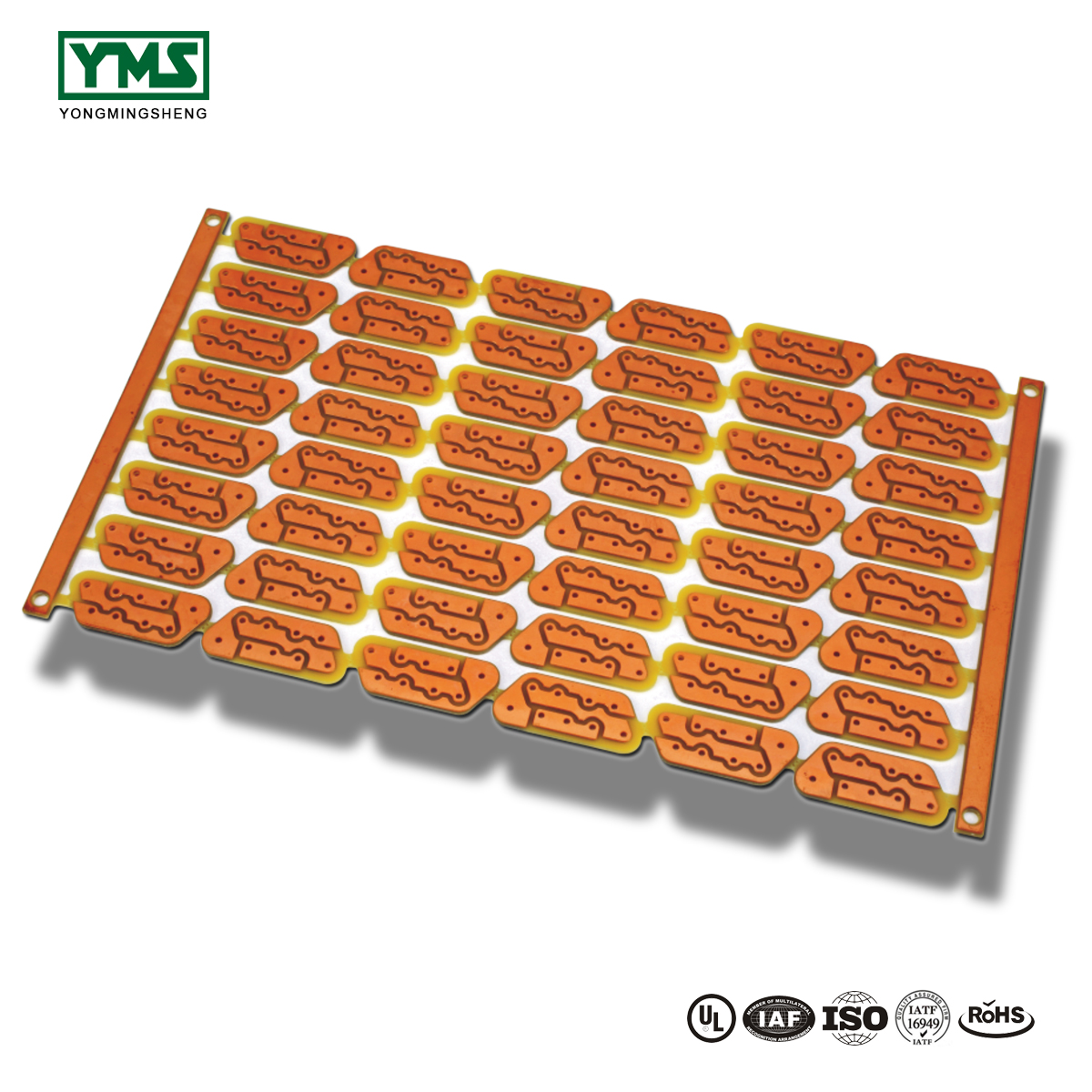

Product detail pictures:

Related Product Guide:

High Density Interconnect(HDI) PCBs Market Research Methodology Focuses On Exploring Major Factors Influencing the Industry Development 2023 key players IBIDEN Group, Unimicron, AT&S, SEMCO, NCAB Group, Young Poong Group, ZDT, Compeq, Unitech Printed Ci | Copper Base Board

Play detective in an old house before renovating it | Life | Fingerprint Lock Rigid-Flexible Pcb

Our team through qualified training. Skilled professional knowledge, powerful sense of support, to satisfy the support desires of consumers for OEM Manufacturer Solder Mask Pcb - Reasonable price Pcb Through Hole Machine,Metal Copper Plating Machine,Pcb Making Machine – Yongmingsheng , The product will supply to all over the world, such as: Latvia, Slovak Republic, Japan, We'll initiate the second phase of our development strategy. Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. If you are interested in any of our products and solutions or would like to discuss a custom order, make sure you feel free to contact us. We've been looking forward to forming successful business relationships with new clients around the world in the near future.

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.