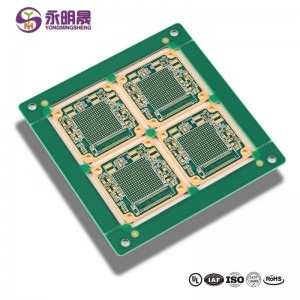

M'mphepete Plating PCB 10 Layer Board m'mphepete plating PCB| YMS PCB

Kodi PCB Edge Plating ndi chiyani?

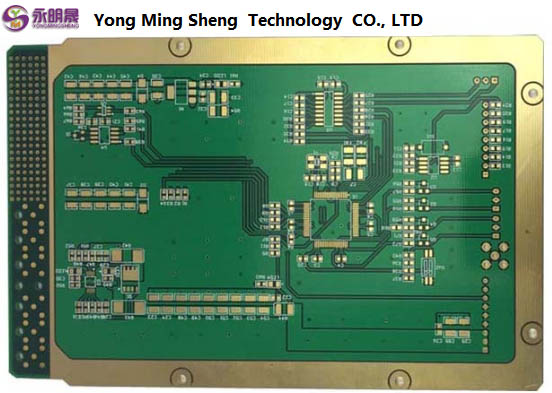

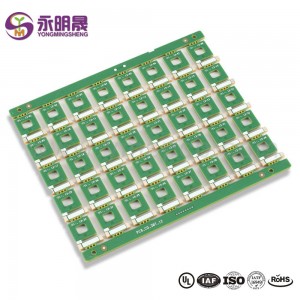

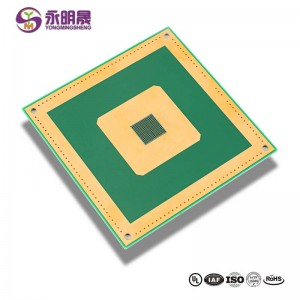

PCB m'mphepete plating ndi ndondomeko kulumikiza pamwamba ndi pansi pa PCB ndi electroplating kuzungulira m'mphepete kunja kwa PCB. Njirayi imathanso kutchedwa sideplating, plating plating, zitsulo zam'mphepete, kapena zopindika. Pazida zomwe zili ndi EMC yapakati kapena yayikulu, kukhulupirika kwa ma siginecha, komanso kutha kwa kutentha, kuyika m'mphepete kumakhala ndi zabwino zake pamtengo wocheperako. Nthawi zambiri, ENIG kapena faifi tambala-golide akulimbikitsidwa kuti akhale njira yomaliza yopangira m'mphepete.

EDGE PLATING PCB NJIRA

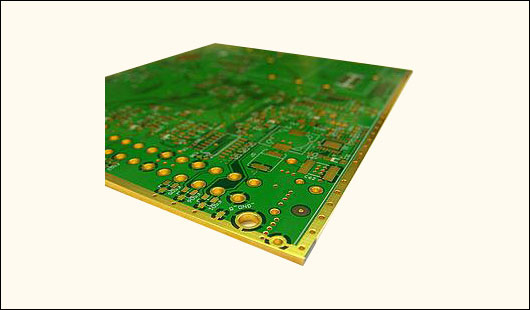

Kupangidwa kwa bolodi losindikizidwa kuti muwotchere m'mphepete kumafuna kuwongolera bwino ndipo kumakumana ndi zovuta zambiri momwe m'mphepete mwake zimakonzedwera komanso kumamatira kwa moyo wonse wazinthu zopukutidwa.

MCL yakhazikitsa machitidwe amakampani ndikupangira izi kuwonetsetsa kuti ma PCB m'mphepeteamakonzekera bwino malo am'mphepete, amapaka mkuwa wonyezimira kuti amamatire nthawi yomweyo ndikuwongolera bolodi kuti awonetsetse kuti gulu lililonse limamatira nthawi yayitali.

By using a controlled process in our circuit board fabrication for edge soldering, we can limit any potential hazard for through-holes and half-holes on the edge. The most significant concern is the creation of burrs, which will lead to the failure of mission-critical parts and can damage your equipment.

MAFUNSO

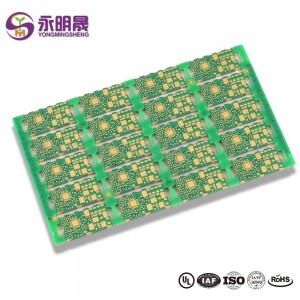

Ma board ozungulira am'mphepete amapezeka m'mafakitale ambiri, ndipo plating m'mphepete ndi mchitidwe wamba. Mupeza PCB m'mphepete castelation (kapena m'mphepete plating PCBs) ntchito nthawi zambiri, kuphatikizapo:

Kupititsa patsogolo luso lonyamula katundu

Mgwirizano wapakati ndi chitetezo

Kuwotchera m'mphepete kuti muwonjezere kupanga

Thandizo labwino la zolumikizira monga matabwa omwe amatsetsereka muzitsulo zazitsulo

Chonde dziwani kuti plating m'mphepete mwa matabwa osindikizidwa ndi chosavuta kuwonjezera nthawi zambiri, koma pamafunika zida ndi maphunziro apadera. Ndi njira yama board ambiri osiyanasiyana, koma nthawi zonse timalimbikitsa kutenga pempho lamtunduwu kwa wopanga, monga MCL, yemwe ali ndi mbiri yodziwika bwino ya gulu lachigawo.

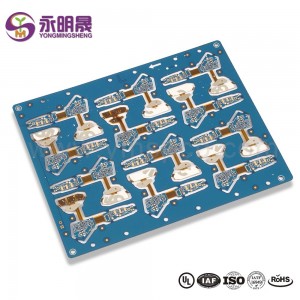

Titha kuchita macheke oyenera a engineering kuti chilichonse chitetezeke. Mwachitsanzo, ma boardboard castellation sayenera kupangitsa kuti ndege zamphamvu zamkati zifike m'mphepete mwa bolodi, chifukwa zimatha kufupikitsa m'mphepete mwake. Pamene mukuyenda, nthawi zonse muzikumbukira kusiyana kwake. Tikamapanga matabwa ozungulira kuti tiwotchere m'mphepete, nthawi zonse timaonetsetsa kuti pali kusiyana pamaso pa plating. Kuyika m'mphepete kumathandizira kupanga kulumikizana kolimba kwa ma PCB ndipo kumatha kuchepetsa mwayi wakulephera kwa chipangizocho. Chifukwa chake, plating m'mphepete imagwiritsidwa ntchito kwambiri pamapulogalamu omwe maulumikizidwe amafunika kuthandizidwa bwino ndipo amakhala chizolowezi chodziwika PCB kupanga . YMS imapereka zida zaukadaulo ndi mainjiniya apadera kuti azipanga njira zopangira mbali. Chonde titumizireni Imelo kapena lemberani ntchito zathu zapaintaneti kuti mumve zambiri za njira yopaka m'mphepete ndi mapangidwe ake.

Zolepheretsa

Chifukwa opanga amafunikira kukhala ndi ma board ozungulira mkati mwa gulu lopanga mu PCb prototype, sangathe kuyika utali wathunthu. Chifukwa chake, pali mipata ina yofunika kuti muyike ma tabo a rout. Imafunikira kuwongolera mbiri ya board board pamalo pomwe ikupanga matabwa ozungulira ndi plating ya m'mphepete, ndikuyika m'mphepete kumafunika musanayambe ntchito yobowola, yomwe imachotsa ma v-cut scoring pa PCB yomwe ikufunika kuyika m'mphepete. .

M'mphepete plating PCB mu YMS

Pokhala ndi zaka zopitilira 10 monga mtsogoleri wamakampani, YMS ili ndi zambiri zopanga za PCB m'mphepete mwa plating, ndipo timatha kuwongolera mawonekedwe apamwamba kwambiri opaka m'mphepete popanda ma burrs. Chifukwa kukhutitsidwa kwa makasitomala ndicho cholinga chathu, tidzayesetsa kupanga bolodi lanu ndipamwamba kwambiri kuti mukwaniritse zomwe mukufuna ndikudzipereka kutsata mfundo zokhwima kwambiri pakupanga ndi kusonkhanitsa PCB.

YMS, mnzake wapamtima wa injiniya wa zamagetsi, akukupatsirani zopanga za PCB zotsika mtengo komanso zapamwamba kwambiri.

Mungakonde:

1, Momwe mungapangire ma frequency apamwamba a PCB

2, Chidziwitso chodziwika bwino cha ma waya a PCB pafupipafupi (1)

3, Chidziwitso chodziwika bwino cha ma waya apamwamba a PCB (2)

Kanema

Dziwani zambiri za zinthu za YMS

Kodi plating mu PCB ndi chiyani?

Muyenera kuti mudamvapo lingaliro ili lotchedwa "m'mphepete plating" kapena "castellation," komwe ndi plating yamkuwa yomwe imayenda kuchokera pamwamba mpaka pansi pa PCB, ndipo imayendetsa m'mphepete mwa mbali imodzi. PCB m'mphepete castellation amaonetsetsa kugwirizana amphamvu mwa bolodi ndi malire mwayi zida kulephera, makamaka kulamulira chitetezo kwa matabwa ang'onoang'ono mawonekedwe factor ndi sub-motherboards.

Kodi copper plating mu PCB ndi chiyani?

Copper plating ndi electro-chemical process, momwe mkuwa umayikidwa pamwamba pazitsulo zolimba pogwiritsa ntchito magetsi.

Copper plating ndi njira yofunika chifukwa:

Zimapereka chitetezo chamtengo wapatali cha dzimbiri.

Iwo bwino kuvala kukana padziko.

Imamatira bwino kwambiri pazitsulo zambiri zoyambira, kuwongolera ductility ya zinthu zokutira.

Ili ndi ma conductivity abwino kwambiri a kutentha komanso mphamvu zamagetsi, zomwe zimapangitsa kuti zinthu zopakidwa zikhale zoyenera kuti zigwiritsidwe ntchito mwaukadaulo, monga ma board osindikizidwa (PCB).