Why won’t aluminum board pcb short circuit?The following follows The Chinese PCB factory to understand:

Aluminum board is metal, but is separated from the line with insulation layer, will not be charged

Aluminum board is a copper clad plate using aluminum as the substrate, with good heat dissipation.We generally use aluminum substrate for circuit boards that need good heat dissipation. In the application of LED lamps, because LED has high heat, if the heat is not dissipated in a timely manner, the brightness will be easily attenuated, or even burn out the chip.Aluminum is a metal with good thermal conductivity, and LED beads mounted on aluminum substrates quickly dissipate the heat.Aluminum substrates are designed with insulating layers that do not conduct electricity. If they did, there would be no way to design circuits on them.

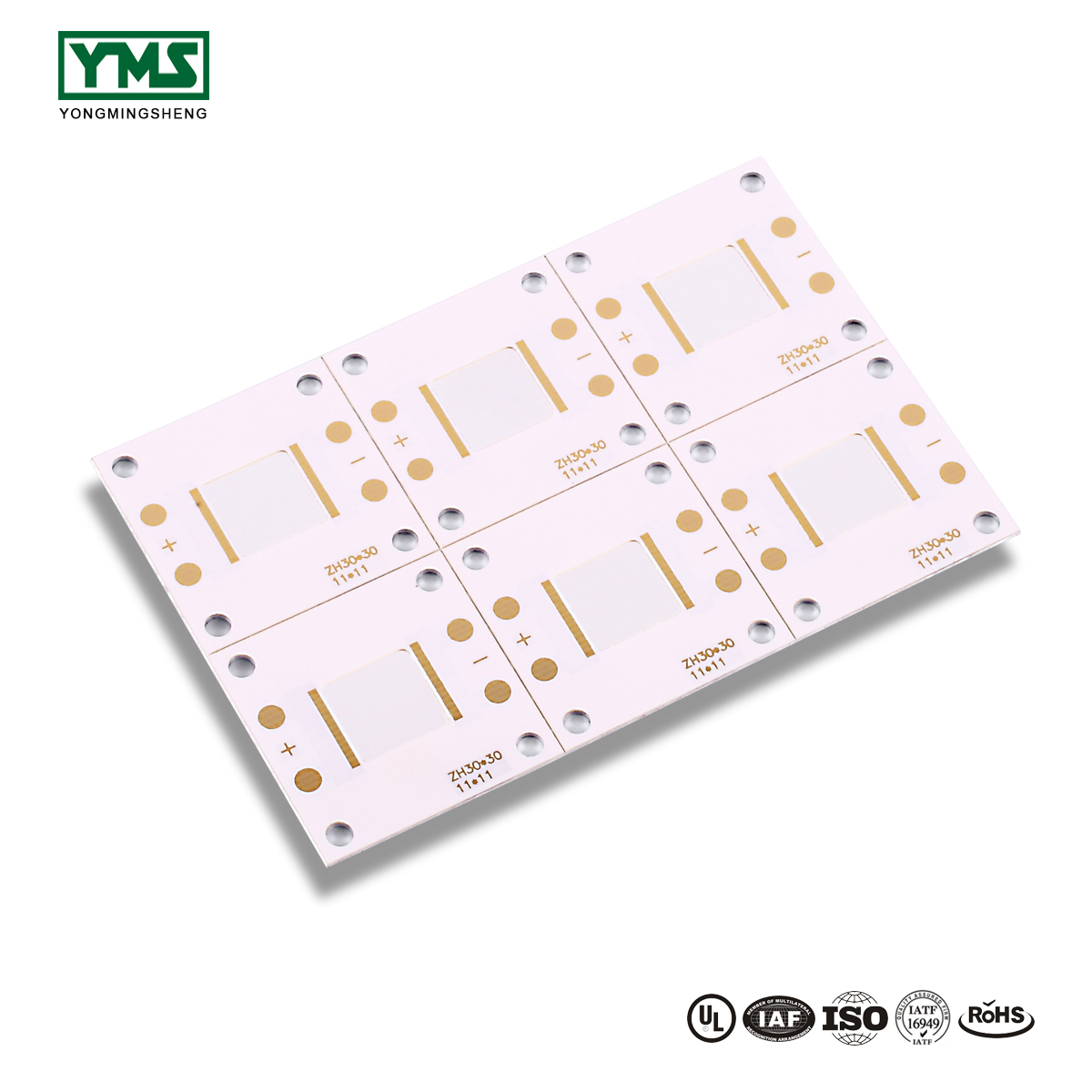

Aluminum board construction

Single – sided aluminum substrate generally has three layers, namely line layer (copper foil), insulation layer and aluminum base.There is a layer of insulation between the line layer and the aluminum base, so there is no short-circuit.The double layer of high end aluminum substrate has two sides of the line layer, of course, the middle of the aluminum base.Multilayer aluminum substrates are rare.

LED lights generally use single-sided aluminum substrate, the circuit layer is mounted with LED, aluminum substrate on the back can be in good contact with the radiator, heat away.

The insulation layer in aluminum board is the most critical, which is the most core technology of aluminum substrate. It should not only stick to copper foil, but also have good thermal conductivity. Because aluminum substrate insulation layer is the biggest thermal conductivity barrier, if the heat of copper foil cannot be rapidly directed to aluminum substrate, aluminum substrate will lose its significance.

Above is the introduction of why aluminum board will not short circuit, I hope you will like;We are a professional PCB manufacturer, welcome to consult ~

Post time: Dec-16-2020