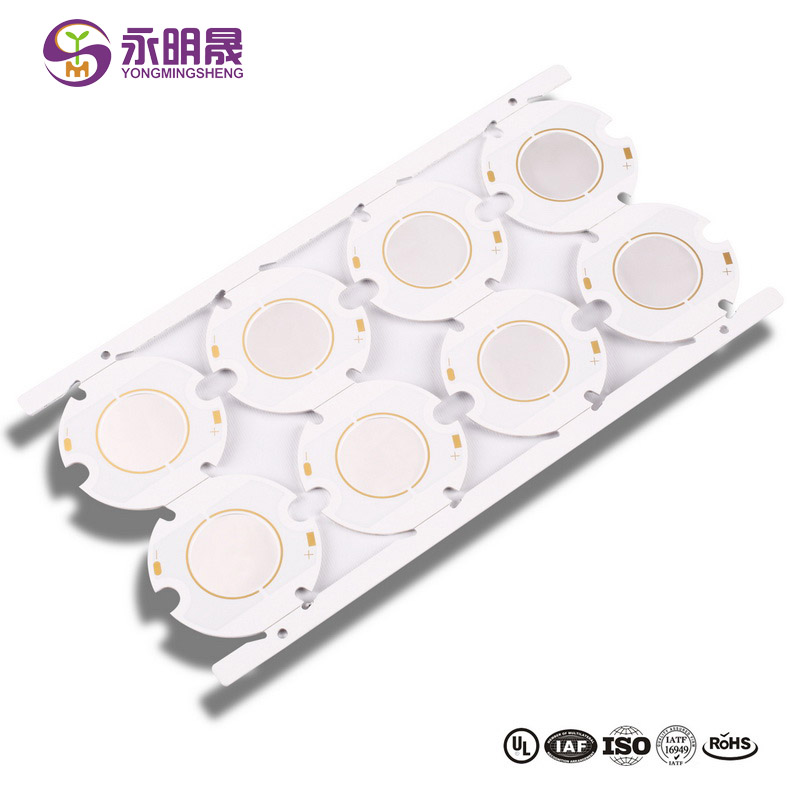

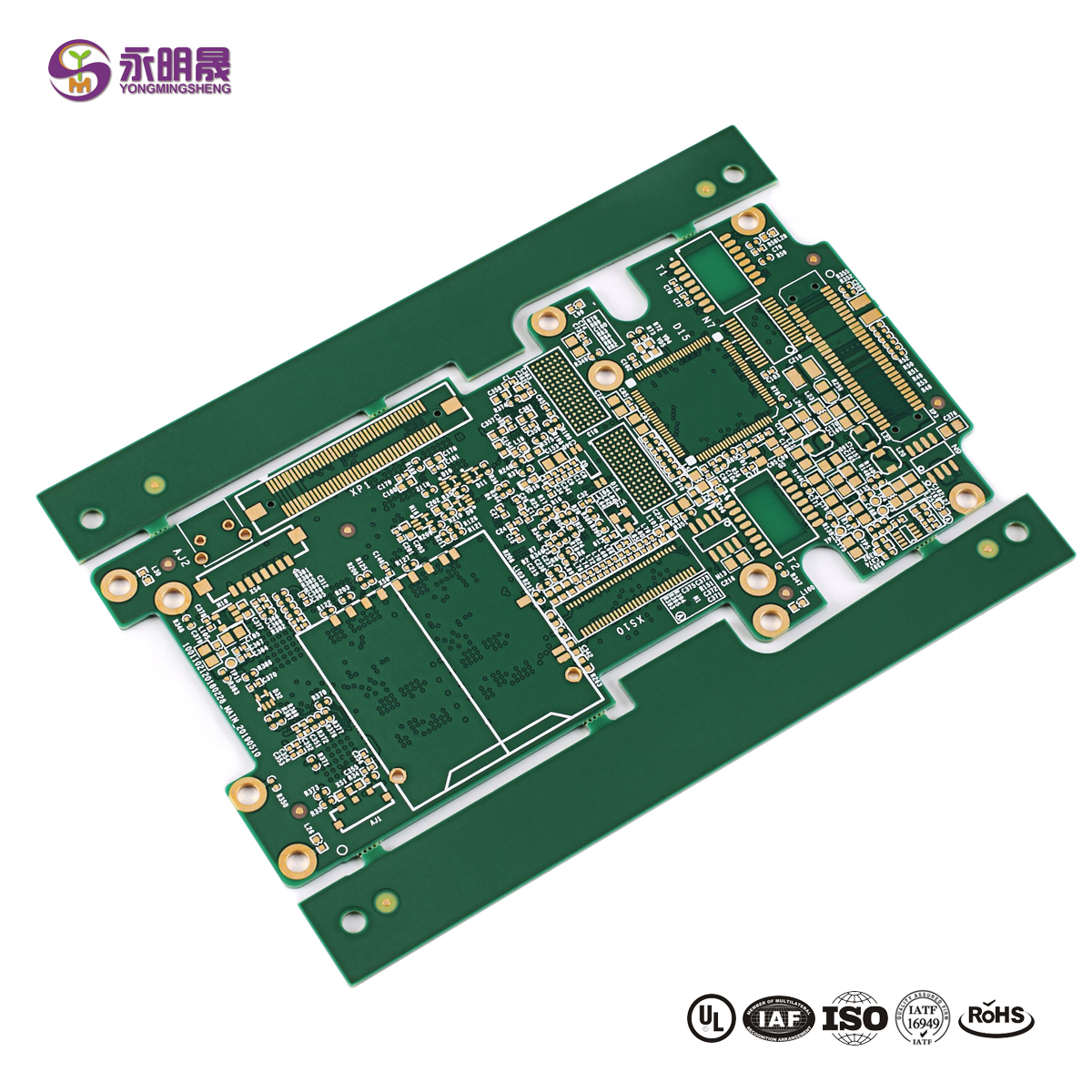

Ceramic PCBs use ceramics as their base materials, and they require much higher manufacturing temperatures than other PCBs. As PCB base materials, ceramics used for PCBs have the advantages of both FR4 and metal. FR4 materials are electrically insulating, but the thermal conductivity is poor; aluminum and copper have excellent thermal conductivity, but they are conductors. Ceramic PCBs have good thermal conductivity and do not require an electrical insulation layer as ceramics are good insulators.

When ceramic PCBs are mounted with LED chips, ICs, and other components, they become ceramic PCBAs. LEDs can be assembled on the ceramic PCBs by wire bonding or flip-chip method. Ceramic PCBAs are usually the core parts in high-power and high-frequency applications, such as car-scale power controllers, variable optical systems, exchange converters, solar power batteries, high-current LED lights...

Why is ceramic PCB so popular?

High Thermal Expansion

The first reason why ceramic boards are so popular in the electronics sector is their excellent thermal coefficient expansion. It is good to note that the ceramic base heat transmission almost matches silicon and can act as a connection material. Besides, you can use it as an isolator. Therefore, there is maximum use for the thermal properties of ceramic boards, even in adverse conditions.

Stability

The application of ceramic brings a stable dielectric capacity, and you can modify the balance into a partial radiofrequency loss to increase your device's power. Still, despite the surface toughness, ceramic materials come with an inherent resistance against chemical erosion. Ceramic's chemical resistance can change to resistance against liquids and moisture.

Versatility

You can create several use cases to integrate a metal core board with a high thermal expansion. Besides, you can still turn the metal core into reliable conductors using the sintering technique. Therefore, the application of ceramic PCB is beneficial because of its high processing temperatures.

Durability

The ceramic board fabrication process creates durability through the use of unique properties, such as toughness. That prevents your PCB from wear and tear. So you can be confident that you will not change your PCB soon because of its slow aging capacity. Also, the high thermal resistance of ceramic PCB makes it assume a decelerated decomposition process.

Adaptability

Lastly, the use of metal cores can serve as inflexible carriers that offer mechanical stiffness. This property makes it easier to use ceramic PCBs in any state of matter because of the high resistance to corrosion and normal wear and tear.

The advantages of ceramic PCB

Heat dissipation is the key benefit that ceramic has over more conventional materials such as FR-4 and metal clad PCB. Because the components are placed directly on the boards, and there is no isolation layer, the flow of heat through the boards is far more efficient. In addition, ceramic material can suffer from high operating temperatures (up to 350°C), what’s more, it has a quite low coefficient of thermal expansion (CTE), allowing for additional compatibility options for PCB design.

Compared with traditional PCBs whose substrate materials are epoxy glass fiber, polyimide, polystyrene and phenolic resin, ceramic PCBs feature the following properties:

Excellent thermal conductivity

Resist chemical erosion

Compatible mechanical intensity

Make it easy to implement high-density tracing

CTA component compatibility

The last point

Traditional PCBs combined with organic foundation substrates progress toward certain extraordinary density, high reliability, good accuracy, and durability with the introduction of chip technology in the electronics industry. Ceramic circuit boards are indeed a new type of PCB that is gaining prominence in the electronics industry due to their distinct characteristics.

Ceramic PCBs provide numerous advantages over conventional boards. Ceramic PCBs are more adaptable, less complex, and function better than conventional circuit boards due to their superior heat conductivity and low expansion coefficient (CTE). Engineers believe that these PCBs are the best choice for miniaturizing cutting-edge electrical gadgets. Hopefully, you got the idea about How to Know the Best Ceramic PCB and now you can pick the best one for you.

Video

Learn more about YMS products

Post time: Feb-25-2022