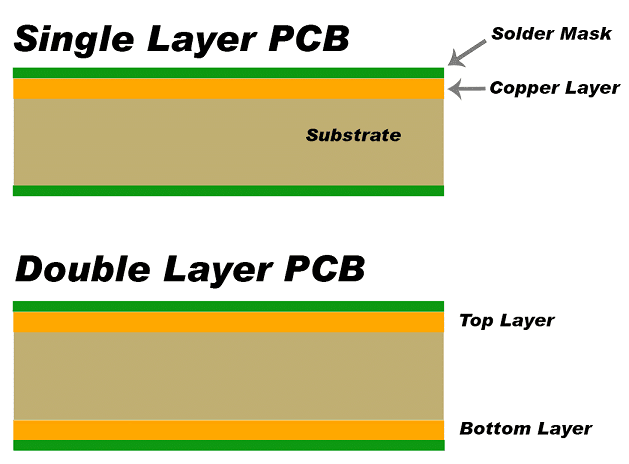

Single-layer PCB contains only one layer of conductive material, most suitable for low density design.

Single-layer PCB have existed since the late 1950s and still dominate the global market in absolute Numbers.

Single-layer printed circuit boards are easy to design and quickly manufactured. They are the most cost-effective platforms in the industry. As with Led Lighting products, most Led PCBS use a layer of PCB, Fr4 or aluminum material.

What is a single-layer PCB?

A thin layer of electrically conductive but electrically insulated dielectric is laminated with the copper. Solder mask is usually applied on top of copper.

Is the material of Single-layer PCB different?

Fr4, CEM1 and cem-3 are normal, and the metal core materials are also popular with single-layer PCBS

Advantages of single-layer PCB

Ideal for simple low-density design, especially for large orders. Less likely to create problems. Most PCB manufacturers are universal and easy to understand;

YONGMINGSHENG produces prototypes, medium and high capacity single-layer circuit boards, with copper thickness from 1 to 20 ounces. Operating temperature ranges from 130°C to 230°C. Single panel offers surface treatment including organic surface protectant (OSP), silver impregnation, tin and gold plating and lead-free hot air solder grade (HASL).

While single-layer PCBS are relatively simple, they can still be used in very complex devices:

The power supply

Relays (automotive and industrial)

Timing circuit

Sensor products

LED lighting

Radio and stereo equipment

Packaging equipment

monitoring

The calculator

The printer

Coffee maker

Vending machine

Solid state drives

Camera system

You May Like:

Post time: Oct-09-2019