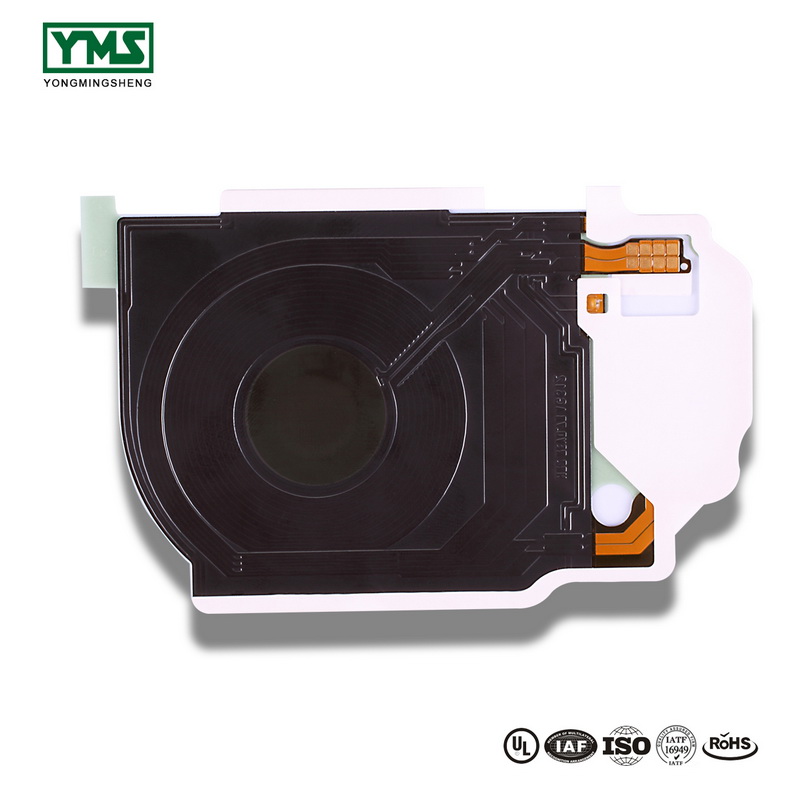

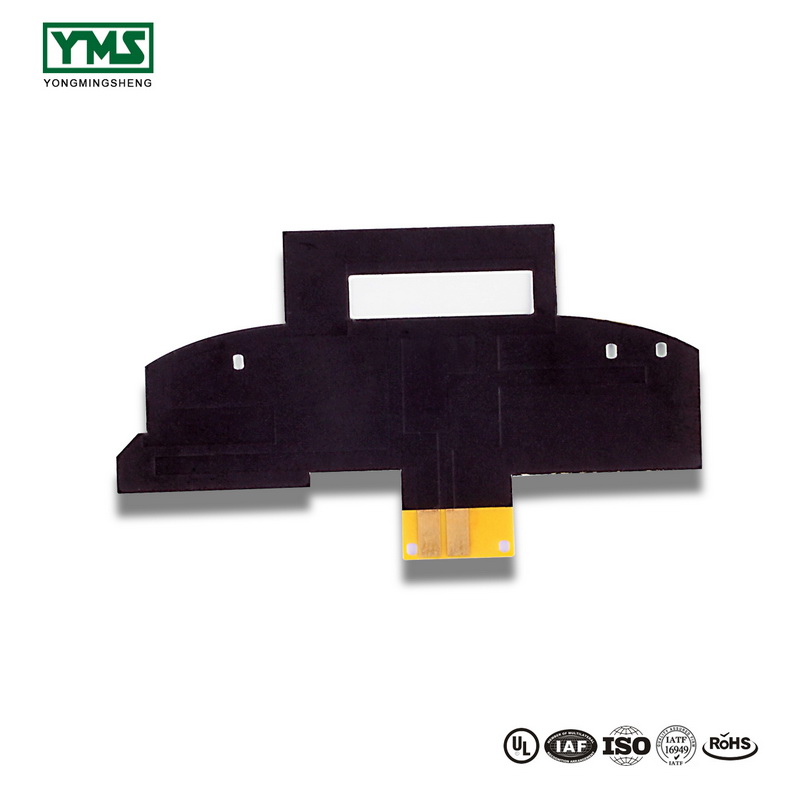

Flexible Board

At present, FPC has: single–layer, double–layer, multi–layer flexible board and Flex-Rigid board.

In the FPC flexible circuit board copying process, the customer asked the most question is time.

There are many reasons for the overflow of FPC flexible circuit board, and FPC manufacturers process parameters, preservation environment, staff operation, coverlay processing process and other related.

Flexible Printed Circuit (FPC) is a highly reliable and Flexible Printed Circuit board based on polyimide or polyester film.

FPC: isn't it common to say that Flexible Printed Circuit means Flexible and Printed Circuit board? It is a conductor circuit pattern made by light imaging pattern transfer and etching process method on a flexible substrate surface.

There are many reasons for the overflow of FPC flexible circuit board, and FPC manufacturers process parameters, preservation environment, staff operation, coverlay processing process and other related.

FPC(Flexible Printed Circuit) means Flexible Printed Circuit board.This kind of circuit board has the advantages of high wiring density, light weight and thin thickness and is widely used in mobile phones, laptops, PDA, digital camera, LCM and many other products.

In addition, FPC breaking is a problem in the early stage, which I personally think is not very difficult. The most fatal problem is FPC ringing, excluding the interference of FPC and over-hole. Do you have any good methods for FPC ringing?

FPC flexible circuit board in the process of processing if do not pay attention to touch the circuit board welding pad with your finger, especially do surface treatment of FPC, the flexible circuit board will cause oxidation.

FPC is the abbreviation of Flexible Printed Circuit, It has the characteristics of high density, light weight and thin thickness. So when designing FPC board, in order to be able to use them better, what are the requirements that we need to follow? The following is a understanding of PCB manufacturers.

Post time: Sep-20-2019