In recent years, with the continuous progress and innovation of electronic technology. It also promotes the development of heavy copper board, not only for printed PCB base board precision and layer number of technical requirements, the PCB substrate material is also constantly put forward higher requirements. Below, China printed circuit board factory introduces "what are the materials of heavy copper board".

General PCB base materials can be divided into two categories:

Rigid base materials and flexible base materials.

An important type of rigid base material is copper clad board. It is made of reinforced stiffener Material, impregnated with resin adhesive, dried, cut and laminated to form a blank, then coated with copper foil, and then processed by high temperature and high pressure forming in a hot press with steel board as a mold.

The prepreg used for multilayer laminates is the semi-finished product of copper-clad laminates in the manufacturing process (mostly made of glass cloth soaked in resin and dried).

1. Classification of copper-clad foils:

There are many classification methods for copper clad foil. Generally, according to the different stiffener materials of the board, it can be divided into five categories: paper base, glass fiber cloth base, composite base (CEM series), laminated multilayer board base and special material base (ceramics, metal core base, etc.).

If according to the board used by different resin adhesive classification, common paper based CCI.There are: phenolic resin (XPc, XxxPC, FR-1, FR-2, etc.), epoxy resin (FE-3), polyester resin and other types.

Common glass fiber bucky CCL has epoxy resin (FR-4, FR-5), which is the most widely used type of glass fiber bucky at present.

In addition, there are other special resins (including glass fiber cloth, polyamide fiber, non-woven cloth, etc.) : bismaleimide modified triazine resin (BT), polyimide resin (PI), diphenyl ether resin (PPO), maleic anhydride -- styrene resin (MS), polycyanate resin, polyolefin resin, etc.

2. According to the fire retardant property classification of CCL:

It can be divided into flame retardant type (UL94 - VO, UL94 - V1 class) and non-flame retardant type (UL94 - HB class).

In recent one or two years, with more emphasis on environmental protection, a new type of CCL without bromine was identified in the flame-retardant CCL, which can be called "green flame-retardant CCL".

With the rapid development of electronic product technology, CCL has higher performance requirements. Therefore, according to the performance classification of CCL, it can be further divided into general performance CCL, low dielectric constant CCL, high heat resistance CCL(the L of general plate is above 150℃), low thermal expansion coefficient CCL(generally used for packaging substrate) and other types.

The above is the introduction of PCB base material. PCB printing process and PCB base material selection can directly affect the final quality and application of PCB, which is also one of the important factors that major industries such as electronics and electric appliances pay more and more attention to PCB material selection.

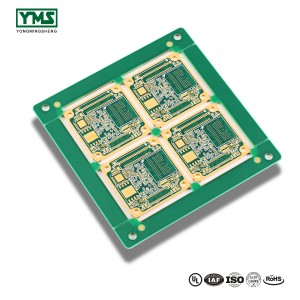

Yongmingsheng technology co., LTD. Is a high-tech company integrating circuit board development, design, proofing, production (processing), testing, production and sales.

The main products are:OSP,ENIG,Lead Free HASL,HAL,Hard Gold PCB, reasonable price;

Since the establishment of the company, from the original professional circuit board processing, to expand the production of flexible circuit board, rigid circuit board, etc.We have been making progress, we have been committed to become a quality PCB manufacturer and service provider.

You May Like:

Post time: Sep-16-2019