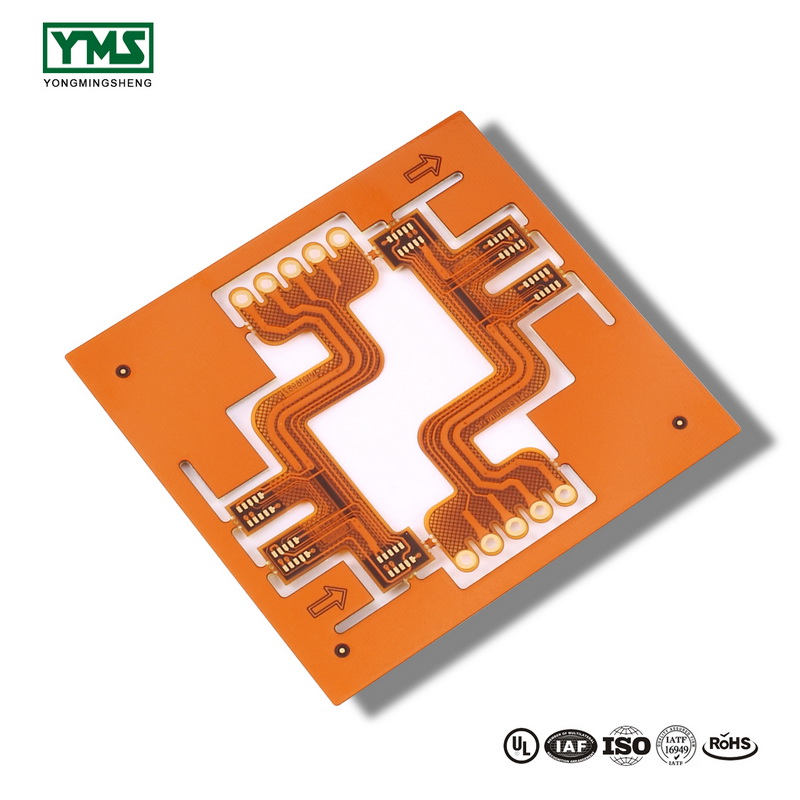

The widespread use of FPC flexible circuit board are popular with the general electronic products manufacturers, good circuit control effect and safer working environment as its own remarkable characteristics of FPC flexible PCB, therefore, FPC flexible circuit board with higher quality as the premise to ensure a better effect.

How can FPC manufacturers improve the quality of flexible circuit board?

1. Design and process in strict accordance with the corresponding production specifications. A good design and production plan is an important premise to ensure the production effect of FPC flexible circuit board.

In order to ensure the use of FPC board effect and quality requirements, YMS is in strict accordance with the production process for operation, and ensure the cutting and drilling and other aspects of the operation method in accordance with its standard mode,so as to improve the quality of FPC board fundamentally.

2. FPC flexible circuit board product screening and use test, to ensure the quality requirements of FPC board must be through a series of tests to select the high quality products.

Every piece of FPC and Flex-Rigid board of YMS production line must go through the open short circuit test, impedance test (customer requirement) ,weldability test thermal ,shock test metallographic micro-slice analysis, halogen-free test and other dozens of tests, and any product must meet customer quality requirements before shipping.

In a word, high-quality FPC manufacturers in the production process will strictly in accordance with the FPC board production process standards for production control. Strict quality screening system is to ensure the maximum quality of FPC products effective method. Good research and development and design ability can ensure better production capacity and more reliable quality.

You May Like

Post time: Aug-22-2019