With the rapid update of electronic products, the waste of printed circuit boards (PCB), the main component of electronic waste, is also increasing.The pollution caused by PCB waste to the environment has attracted the attention of many countries.

The waste PCB contains heavy metals such as lead, mercury, hexabalent chromium, and toxic chemicals such as polybrominated biphenyl (PBB) and polybrominated diphenyl ether (PBDE) as flame retardants. In the natural environment, these substances will cause great pollution to groundwater and soil, and bring great harm to people’s life and physical and mental health.

The waste PCB, containing nearly 20 kinds of non-ferrous and rare metals, has high recycling value and economic value, and is a real mine waiting to be mined.China PCB factory has sorted out several methods of disposing waste circuit boards to share with you:

Physical method

Physical method is a method to realize recycling by mechanical means and PCB physical properties.

1.1 the broken

The purpose of crushing is to dissociate the metal from the organic matter as much as possible in the waste circuit board so as to improve the sorting efficiency.It is found that when the crushing is 0.6mm, the metal can basically achieve 100% dissociation, but the choice of crushing mode and grade depends on the subsequent process.

1.2 sorting

Separation is realized by the difference of physical properties such as density, particle size, electrical conductivity, magnetic conductivity and surface characteristics.At present, there are some widely used technologies, such as wind turbine technology, flotation separation technology, cyclone separation technology, flotation separation and eddy current separation technology.

Supercritical Treatment Technology

Supercritical fluid extraction (sfe) is a method of extraction and purification using the influence of pressure and temperature on the solubility of supercritical fluid without changing chemical composition.

Compared with traditional extraction methods, supercritical CO2 extraction process has the advantages of environmental friendliness, convenient separation, low toxicity, little or no residue, and can be operated at room temperature.

The main research direction of using supercritical fluid to treat waste PCB focuses on two aspects:

1. Supercritical CO2 fluid has the ability to extract resins and brominated flame retardants from printed circuit boards.

When the resin binding material in the PCB is removed by supercritical CO2 fluid, the copper foil layer and glass fiber layer in the PCB can be easily separated, thus providing the possibility of efficient recovery of the material in the PCB.

2. Extraction of metal in waste PCB by supercritical fluid.

The extraction efficiency of Cd2+, Cu2+, Zn2+, Pb2+, Pd2+, As3+, Au3+, Ga3+ and Sb3+ from cellulose filter paper or sand of simulated samples was above 90%.

Supercritical treatment technology also has great defects, such as: high selectivity of extraction requires the addition of entrainers, which will harm the environment;High extraction pressure requires more equipment.High temperature is used in the extraction process, so energy consumption is high.

Chemical method

Chemical treatment technology is a process to extract different chemical stability of various components in PCB.

3.1 heat treatment

Heat treatment is a method of separating organic matter and metal by means of high temperature.It mainly includes incineration method, vacuum cracking method, microwave method and so on.

3.1.1 incineration method

Incineration method is to break up the electronic waste to a certain particle size, send it to an incinerator for incineration, decompose the organic components, and separate the gas from the solid.

The residue after incineration is bare metal or its oxide and glass fiber, which can be recovered by physical and chemical methods.The gases containing organic components are discharged after combustion in the secondary incinerator.The disadvantage of this method is that it produces a large amount of waste gas and toxic substances.

3.1.2 cracking method

Cracking, also known as dry distillation in industry, involves heating e-waste in a container without air, controlling temperature and pressure so that the organic material is broken down and turned into oil and gas, which is collected by condensation and recycled.

Different from the incineration of electronic waste, the vacuum pyrolysis process is carried out under the condition of no oxygen, so the production of dioxins and furans can be inhibited, the amount of waste gas produced is small, and the environmental pollution is small.

3.1.3 microwave processing technology

Microwave recycling method is to break up electronic waste, and then use microwave heating, so that organic compounds thermal decomposition.Heating to around 1400 ℃ melts glass fibers and metals to form a vitrified substance, which cools and separates gold, silver and other metals in the form of beads. The remaining glass material can be recycled for use as building materials.

This method is significantly different from the traditional heating method and has the advantages of high efficiency, high speed, high utilization rate of resource recovery and low energy consumption.

3.2 hydrometallurgy

Hydrometallurgical technology is mainly used to remove metal from electronic waste and recycle it from liquid phase by taking advantage of the characteristics that metal can be dissolved in acid such as nitric acid, sulfuric acid and aqua regia.It is a widely used method to deal with electronic waste.

Compared with pyrometallurgy, hydrometallurgy has the advantages of less waste gas emission, easy to deal with residue after metal extraction, remarkable economic benefits and simple technological process.

biotechnology

Biotechnology is the use of microbial adsorption on mineral surface and microbial oxidation to solve the problem of metal recovery.

Microbial adsorption can be divided into two types: using microbial metabolites to fix metal ions and using microorganisms to fix metal ions directly.

The former is fixed by hydrogen sulfide produced by bacteria, and when ions adsorbed on the surface of bacteria reach a saturated state, flocs can be formed and settle down.

The latter is to use the oxidation of ferric ion to oxidize other metals in the alloy of gold and other precious metals into soluble substances and enter the solution, so that the precious metal is exposed for easy recovery.

The extraction of gold and other precious metals by biological technology has the advantages of simple process, low cost and convenient operation, but the extraction time is long and the extraction rate is low.

conclusion

Electronic waste is a valuable resource. It is of great significance to strengthen the research and application of metal recycling technology of electronic waste from both economic and environmental perspectives.

Due to the complex and diverse characteristics of electronic waste, it is difficult to recover the metal with any single technology. In the future, the development trend of electronic waste treatment technology should be: industrialization of treatment forms, maximization of resource recovery, and scientific treatment technology.

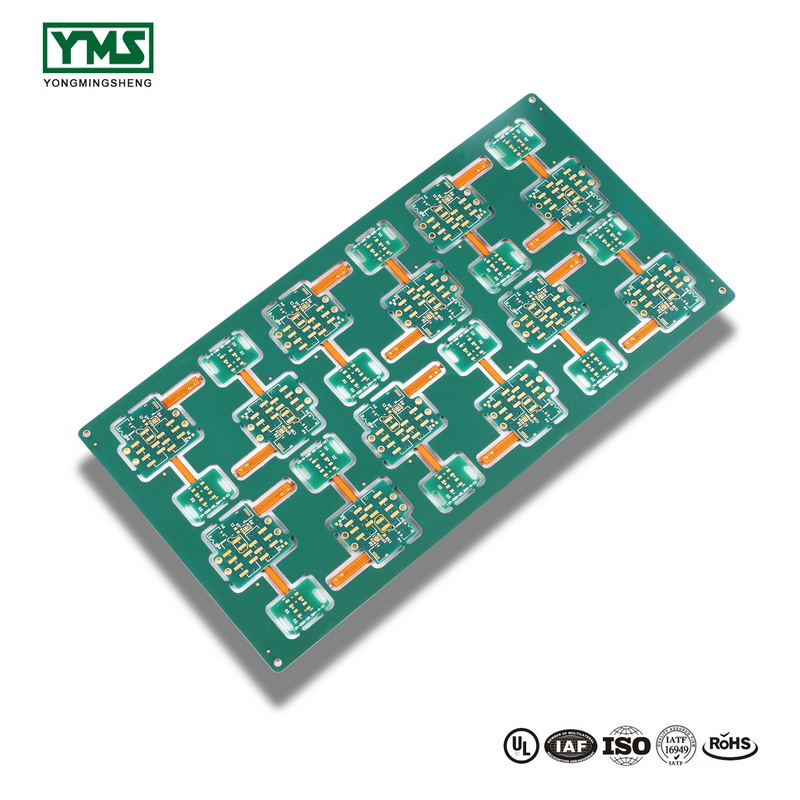

OSP, Select OSP,Flash Gold,Thick Gold FPC

To sum up, the research on recycling of waste PCB can not only protect the environment and prevent pollution, but also be beneficial to the recycling of resources, save a lot of energy and promote the sustainable development of economy and society.

Post time: Aug-27-2019