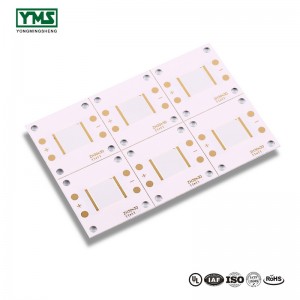

Yongmingsheng professional aluminum substrate pcb manufacturers take you to learn about different aluminum substrate.

Aluminum substrate is a kind of metal-based copper clad plate with good heat dissipation function. Generally, a single panel consists of a circuit layer (copper foil), an insulating layer and a metal base layer.Double panel is mainly used for high-end use, structure for circuit layer, insulation layer, aluminum base, insulation layer, circuit layer.

First the composition of the aluminum substrate

1. Line layer

Circuit layers (typically electrolytic copper foil) are etched to form printed circuits for assembly and connection of devices that can carry higher currents.

2. Insulation layer

Insulation layer is the core technology of aluminum substrate, which mainly plays the functions of bonding, insulation and heat conduction.Aluminum substrate insulation layer is the largest thermal conductivity barrier in power module structure.The better the heat conduction performance of the insulation layer is, the more conducive to the diffusion of heat generated during the operation of the device, and the more conducive to reducing the operating temperature of the device, so as to improve the power load of the module, reduce the volume, prolong the life, improve the power output and other purposes.

3. metal base

What kind of metal is used for the insulation metal substrate depends on the thermal expansion coefficient, heat conduction ability, strength, hardness, weight, surface state and cost of the metal substrate.

In general, from the cost and technical performance to consider, aluminum plate is the ideal choice.There are 6061,5052,1060 aluminum plates for choice.

Two the advantages of aluminum substrate:

Aluminum substrate is a low alloying Al-Mg-Si high plastic alloy plate, it has good thermal conductivity, electrical insulation performance and mechanical processing performance, aluminum substrate compared with the traditional FR-4, can carry a higher current, its voltage resistance up to 4500V, thermal conductivity is greater than 2.0, in the industry to aluminum substrate.

Aluminum substrate also has the following unique advantages:

● Surface mount technology (SMT);

● In the circuit design scheme for the heat diffusion is very effective treatment;

● Reduce the product operating temperature, improve the product power density and reliability, prolong the service life of the product;

● Reduce product volume, reduce hardware and assembly costs;

● Replace fragile ceramic substrate for better mechanical endurance.

Aluminium substrate is used in a wide range of applications, such as audio equipment input, output amplifier, balance amplifier;CPU board 'floppy disk drive, power supply device of computer;Electronic regulator, igniter, power supply controller of automobile;Luminaires, LED lights, etc. all use aluminum substrate.

I hope this article has been helpful to you.We are a professional supplier of aluminum substrate from China - Yongmingsheng Technology. Welcome to consult us!

Searches related to aluminum pcb:

Post time: Feb-02-2021