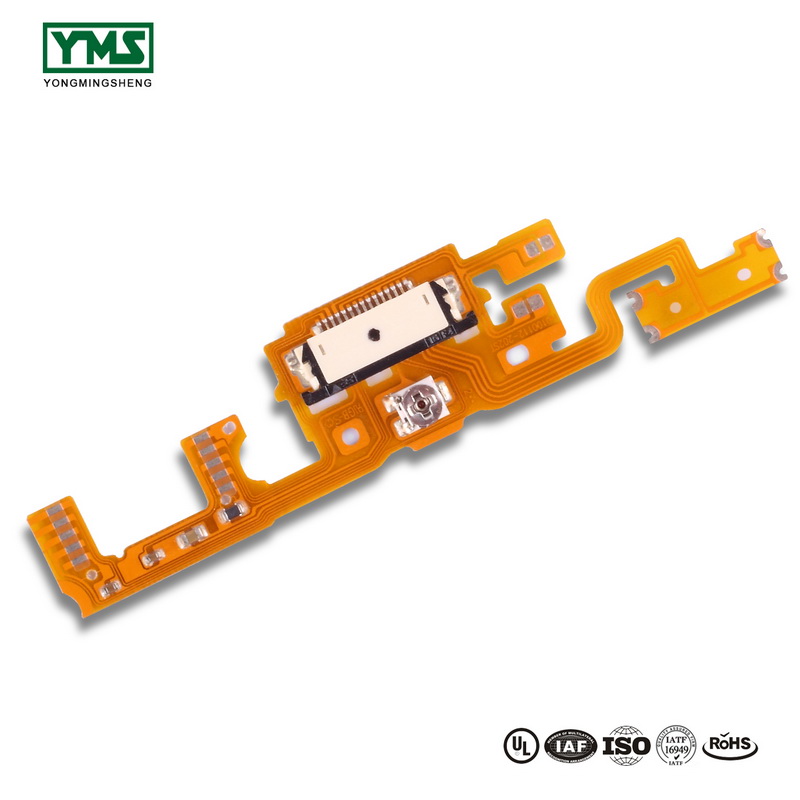

FPC flexible circuit board can only work for electronic products after SMT patch, every part of FPC circuit board is very important, so the details of every step is very important in the production, then what are the components of FPC board?

1. Dielectric layer: used to maintain the insulation between the lines and the layers, commonly known as the substrate.

2. Screen printing: this is not necessary, its main function is to mark the name and position box of each part on the circuit board, which is convenient for maintenance and identification after assembly.

3. Circuit and drawing: the circuit is used as a tool for conducting between the original parts. Large copper surface will be designed as grounding and power layer in the design.The line is made at the same time as the drawing.

4. Surface treatment: the main factor that directly determines the quality and positioning of a FPC flexible circuit board is the surface treatment process. Currently, the common surface treatment processes include gold deposition, silver deposition, gold plating, tin plating, OSP, etc.

5. Cover film: FPC cover film can be generally called protective film, the main role is to protect copper foil from exposure to air, avoid the oxidation of copper foil;Provides coverage for subsequent surface treatments and ACTS as a solder resist in SMT.

6. Hole: the conduction hole can make more than two layers of lines to conduct each other.

YMS is a flexible printed circuit board manufacturer in China, We offer competitive price with high quality single layer FPC,double layer FPC,semi flex FPC.

Post time: Aug-23-2019