Chinese PCB manufacturer tells you

All high frequency PCBS operating at or above 100 MHz are called RF PCBS, while microwave RF PCBS operating at or above 2GHz. Compared to traditional PCB, the development process involved in RF PCB is different. RF microwave PCB is more sensitive to various parameters, which have no effect on ordinary PCB. Therefore, development also takes place in a controlled environment with the required expertise.

RF microwave PCB applications

RF microwave PCBS are used in a variety of wireless technology-based products. If you are developing robots, smartphones, security applications or sensors, you need to choose the perfect RF microwave PCB for your product.

As technology advances, new designs and products are coming to market every day. These advances have led to major changes in electronics. It is of great interest to product developers to find the right PCB for their products to ensure smooth operation and long life.

Finding the perfect RF microwave PCB can be stressful for your project, especially when choosing the right PCB material. It is of great interest to the project developer that his PCB may be an advanced material with appropriate functionality and should be delivered in a timely manner.

When RF and other parameters select the perfect PCB material, microwave energy level, operating frequency, operating temperature range, current and voltage requirements are very important.

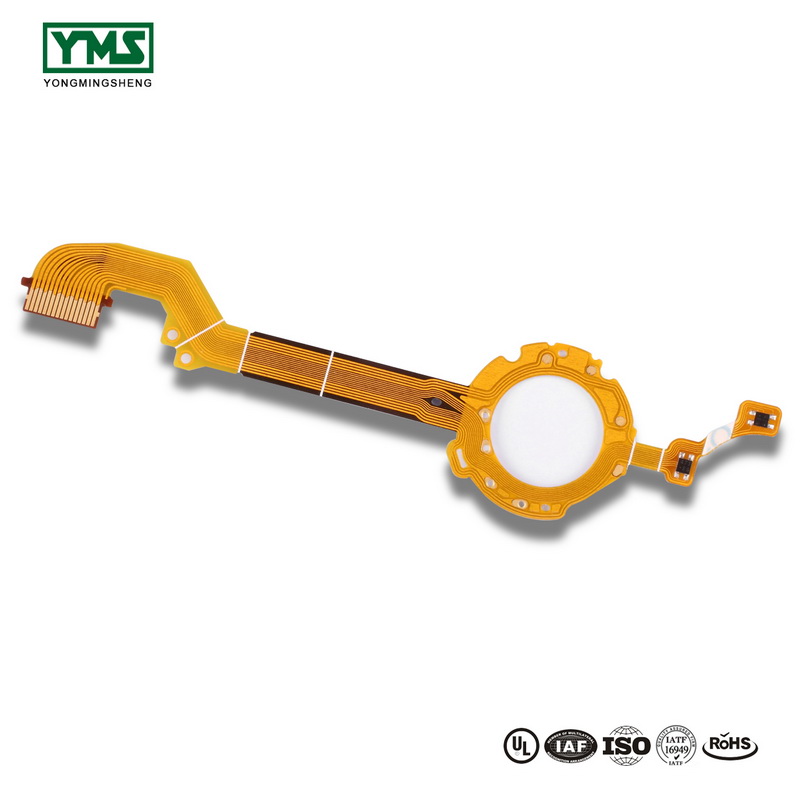

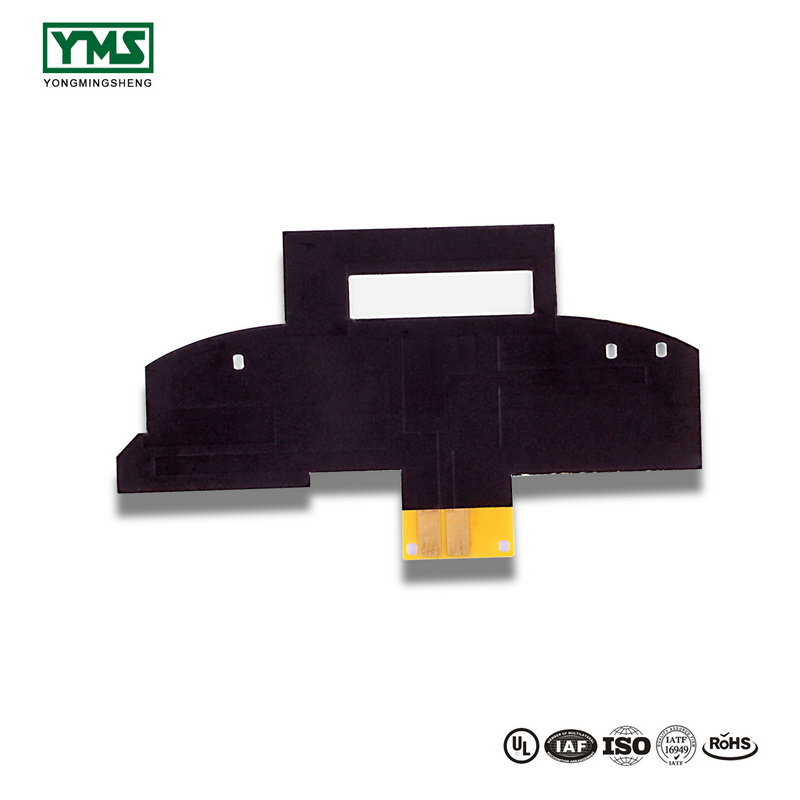

When you start manufacturing PCB, please make sure that you have selected the specifications suitable for your PCB. Conventional high frequency RF microwave frequencies are single-layer PCB built on a dielectric. However, with the development of RF microwave PCB design, many technologies have emerged in the past few decades.

Why do you need to focus on choosing the right manufacturer?

Ordering a PCB from a low-cost manufacturing plant equipped with high-tech equipment is more advantageous than manufacturing it using lower-grade materials.

RF PCB is very sensitive to noise, impedance, electromagnetic and ESds. High quality PCB manufacturers focus on eliminating any impact factors in the manufacturing process. Poor quality RF microwave PCBS are not expected to last long, which is why choosing the perfect RF PCB manufacturer can change your product experience.

Today, most modern RF PCB manufacturing plants use computer-aided engineering software simulation programs for PCB manufacturing. The biggest advantage of cad-based rf microwave PCB manufacturing is that it has simulation models of various brands and PCB models with appropriate product specifications.

These parameters are critical for standardizing the production of RF microwave PCBS and ensuring reliability. In addition, these machines also support manual operation, allowing operators to perform manual operation.

Therefore, it is clear that manufacturing RF microwave PCBS is not as simple as it looks.

You May Like

Post time: Jan-15-2020