Aluminum PCB Manufacturing Process

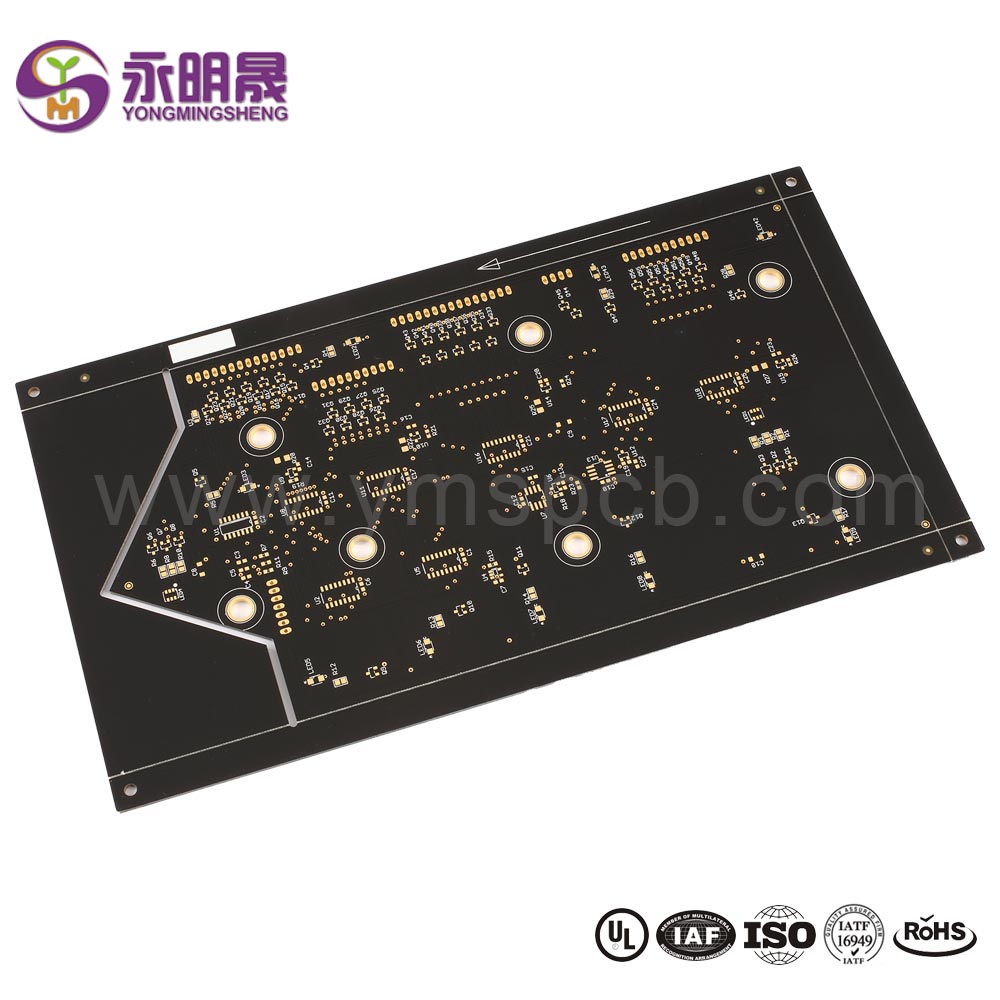

Aluminum PCB Manufacturing ProcessThe manufacturing process of aluminum PCB with OSP surface finish: Cutting→Drilling→Circuit→Acid/alkaline etching→Solder Mask→Silkscreen→V-cut→PCB Test→OSP→FQC→FQA→Packing→Delivery.

The manufacturing process of aluminum PCB with HASL surface finish: Cutting→Drilling→Circuit→Acid/alkaline etching→Solder Mask→Silkscreen→HASL→V-cut→PCB Test→FQC→FQA→Packing→Delivery.

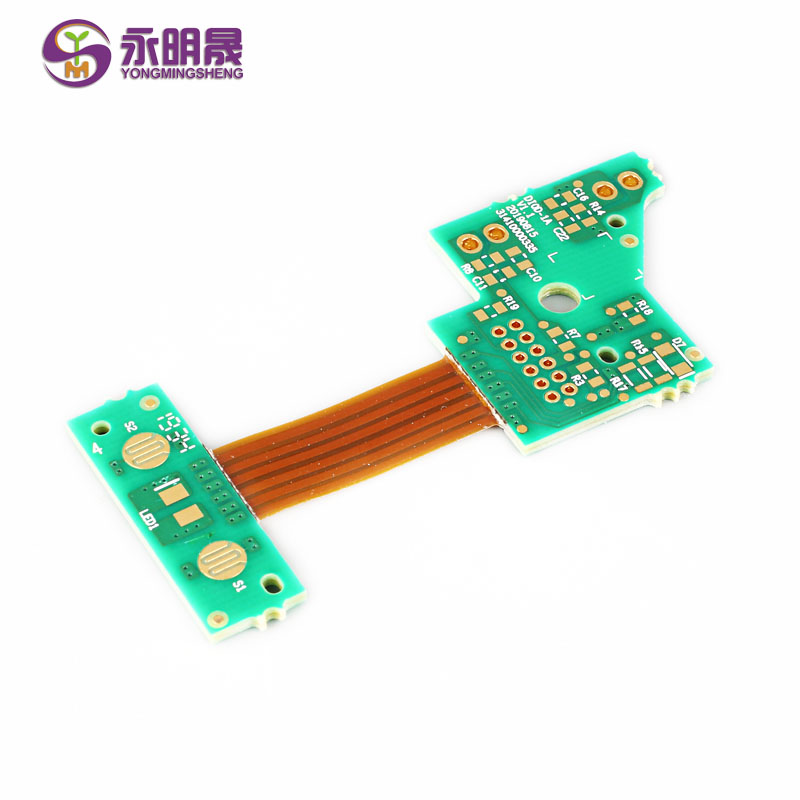

YMSPCB can provide the aluminum core PCB with the same surface finish process as FR-4 PCB: Immersion Gold / thin / silver, OSP, etc.

In the process of manufacturing an aluminum PCB, a thin layer of dielectric is added between the circuit layer and the base layer. This layer of dielectric is both electrically insulating, as well as thermally conductive. After adding the dielectric layer, the circuit layer or the copper foil is etched

Notice

1. Put boards in the cage-shelf or separate them with paper or plastic sheets to avoid scratches during transportation of the whole production.

2. Using a knife to scratch an insulated layer in any process is not allowed during the whole production.

3. For abandoned boards, the base material cannot be drilled but is only marked with “X” by oil-pen.

4. Total pattern inspection is a must because there is no way to solve the pattern problem after etching.

5. Conduct 100% IQC checks for all out-sourcing boards according to our company’s standards.

6. Gather all defective boards together (such as dim color & scratches of the AI surface) to be re-processed.

7. Any problem during production must be informed to related technical staff in time to be solved.

8. All processes must be strictly operated following requirements.

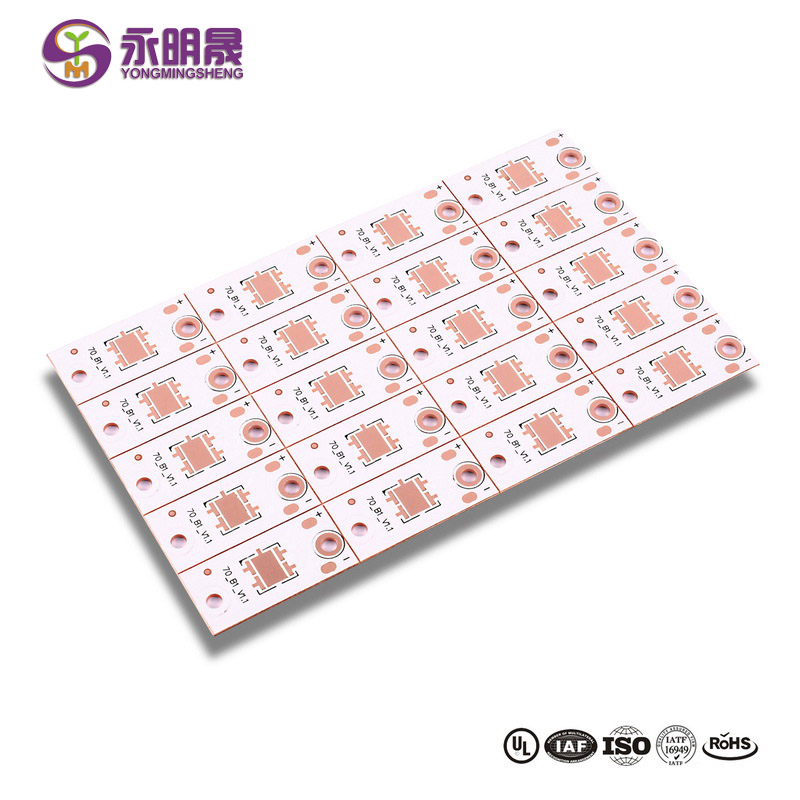

Aluminum printed circuit boards are also known as metal base PCBs and are comprised of metal-based laminates covered by copper foil circuit layers. They are made of alloy plates that are a combination of aluminum, magnesium and silumin (Al-Mg-Si). Aluminum PCBs deliver excellent electrical insulation, good thermal potential and high machining performance, and they differ from other PCBs in several important ways.

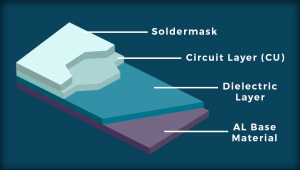

Aluminum PCB Layers

THE BASE LAYER

This layer consists of an aluminum alloy substrate. The use of aluminum makes this type of PCB an excellent choice for through-hole technology, discussed later.

THE THERMAL INSULATION LAYER

This layer is a critically important component of the PCB. It contains a ceramic polymer that has excellent viscoelastic properties, great thermal resistance and defends the PCB against mechanical and thermal stresses.

THE CIRCUIT LAYER

The circuit layer contains the copper foil mentioned previously. Generally, PCB manufacturers use copper foils ranging from one to 10 ounces.

THE DIELECTRIC LAYER

The dielectric layer of insulation absorbs heat as current flows through the circuits. This is transferred to the aluminum layer, where the heat is dispersed.

Achieving the highest light output possible results in increased heat. PCBs with improved thermal resistance extend the life of your finished product. A qualified manufacturer will provide you with superior protection, heat mitigation and part reliability. At YMS PCB, we hold ourselves to the exceptionally high standards and quality your projects require.

Learn more about YMS products

People also ask

Post time: Jan-20-2022

Board5.jpg)