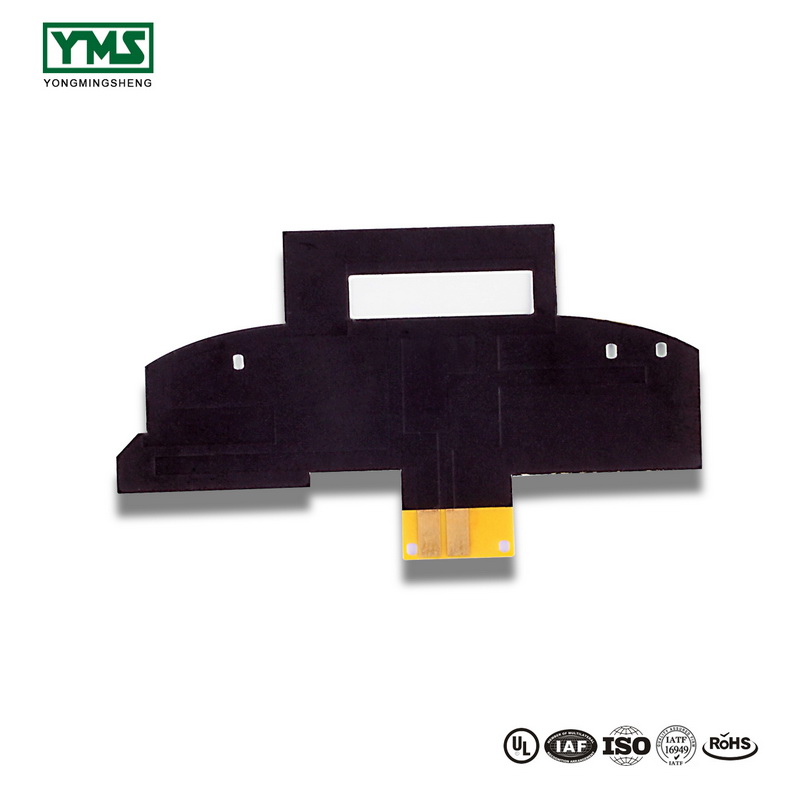

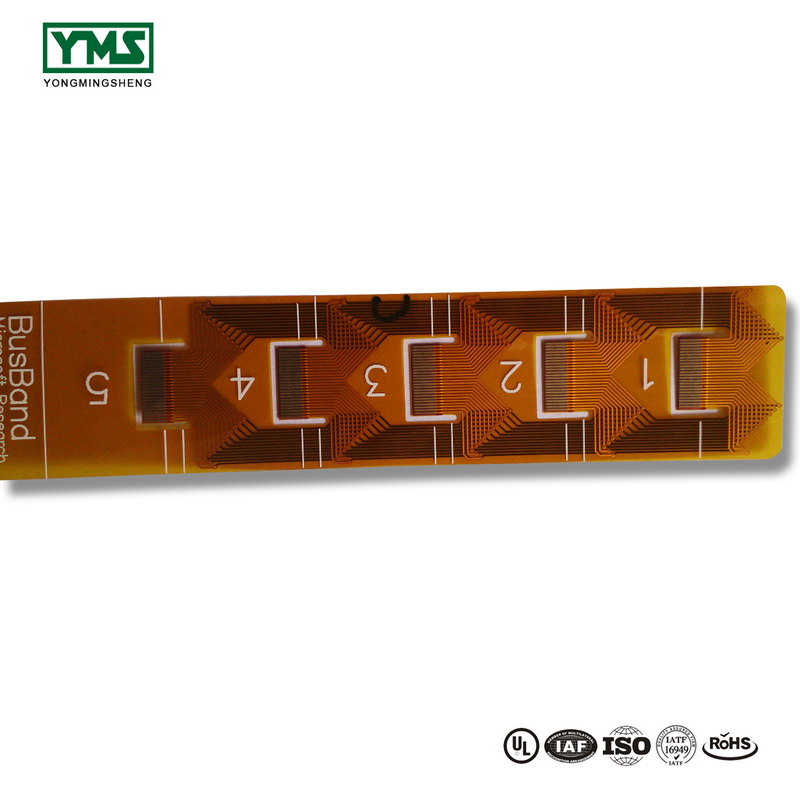

FPC is the abbreviation of Flexible Printed Circuit, It has the characteristics of high density, light weight and thin thickness.

So when designing FPC board, in order to be able to use them better, what are the requirements that we need to follow?The following is a understanding of PCB manufacturers.

Design the thickness of FPC soft board

In general, the number of signal layers, the number and thickness of the power plate, the aspect ratio of aperture and thickness required for quality punching and plating, the length of pin required for automatic insertion of components and the type of connection used will all affect the thickness of the plate.

Design the size of FPC flexible board

As for the size of electronic board, it is mainly optimized according to the application requirements, system box size, circuit board manufacturer’s limitations and manufacturing capacity.

In addition to the above two factors to consider, in order to minimize the distortion of the FPC flexible board to get a flat finish board, the layers of the multilayer FPC substrate should remain symmetrical.

That is, it has an even number of copper layers, and ensures that the thickness of copper and copper foil pattern density of the plate layer are symmetric.Therefore, in order to ensure the normal use of circuit board, it is necessary to follow the above steps when designing them.

Post time: Aug-26-2019