FPC is flexible circuit board, flexible circuit board is made of polyimide or polyester film as a kind of printed circuit board with high reliability and excellent flexibility.

Short for flexible board or FPC, with high wiring density, light weight, thin thickness.

FPC is mainly used in mobile phones, laptops, pdas, digital cameras, LCM and many other products. Here are some common terms of FPC.

1. Access Hole

Usually refers to the Coverlay(holes to be cut out first) of the surface of the flexible board, which is used to fit on the surface of the flexible board circuit as an anti-welding film. However, it is necessary to deliberately expose the hole ring hole wall or square welding pad for welding of parts. "Access holes "are holes in the surface that allow the outside world to "Access" the solder joints on the surface below the sheath. Some multi-layer board also have such outings.

2. Acrylic

Is the common name of polyacrylic resin, most of the flexible board use its film.

3. Adhesive

A substance, such as resin or paint, that makes two interfaces bond.

4. Anchoring Spurs

In the middle panel or single panel, in order to make the hole ring welding pad has stronger adhesion property on the panel surface, it can add some fingers on the extra space outside the hole ring to make the hole ring more consolidated, so as to reduce the possibility of floating away from the panel surface.

5. Bandability

One of the characteristics of a Dynamic Flex Board, such as the printed Heads of a computer disk drive, that is to perform a billion "flexural tests."

6. Bonding Layer

Usually refers to the film layer of a multi-layer board, or TAB tape, or sheet of flexible board, the adhesive layer between copper sheet and polyimide (PI) substrate.

7. Cover /Cover Coat

For the outer circuit of the soft board, its welding resistance is not easy to adopt the green paint used by the hard board, because it may fall off during bending. Need to use a soft "acrylic" lamination on the board, can be used as an anti-welding film and can protect the outer circuit, and enhance the resistance and durability of the soft board, this special "outer film" is called the surface protection layer or protective layer.

8. Dynamic Flex (FPC)

A flexible circuit board that needs to be used for continuous movement, such as the floppy board in the read/write head of a disk drive. In addition, the "static FPC" is refering to the flexible board that no longer has any action after properly assembling.

9. Film Adhesive

Refers to the dry lamination of the next layer, can contain reinforcing fiber cloth film, or do not contain reinforcing material only the thin layer of the next agent material, such as the FPC is the next layer.

10. Flexible Printed Circuit, FPC

A special circuit board with a flexible polyimide (PI) or polyester (PE) substrate capable of three dimensional shape changes during downstream assembly. Like a hard board, this soft board can be made into a plated through-hole or surface pad for through-hole mounting or surface mounting. The board surface can also be attached with the Cover Layer for the purpose of soft protection and anti-welding, or printed with soft anti-welding green paint.

11. Flexural Failure

Flexural Failure refers to the fracture or damage to a material (plate) resulting from repeated Flexural Failure.

12. Kapton

This is the business name of dupont products, is a "polyimide" sheet of insulating soft material, attached to the calendered or plated copper foil, can be made into a flexible board (FPC) substrate

13. Membrane Switch

With transparent Mylar film as the carrier, SilverPastes (or silver paste) are printed with thick film lines by screen printing. Then, with hollow spacers, they are combined with protruded panels or PCB to become "touch-operated" switches or keyboards. This small "key" device, often used in hand-held calculators, electronic dictionaries, and some household appliances remote control, is called "membrane switch".

14. Polyester Films

Short for PET flakes, the most common is dupont's product MylarFilms, which is a material with good electrical resistance. In the circuit board industry, the transparent protective layer of the imaging dry film surface, as well as the Coverlay of FPC surface anti-welding, are PET films. In addition, it can also be used as the substrate of the silver paste printing thin film circuit.

15. Polyimide (PI)

Kerimid 601, a fine resin polymerized by Bismaleimide and Aromaticdiamine, is first known by rhone-poulenc of France. Dupont made it into a sheet called Kapton. This kind of PI board heat resistance and electrical resistance are very superior, is an important raw material for flexible board (FPC) and automatic combination of tape (TAB), is also an important board for advanced military hard board and supercomputer host board.

16. Reel to Reel

Some electronic components can be produced by rolling wheel (disk) retractable manufacturing process, such as TAB, IC Lead Frame, FPC, etc., with the convenience of retractable tape, the on-line automatic operation can be completed, so as to save the time and labor cost of single operation.

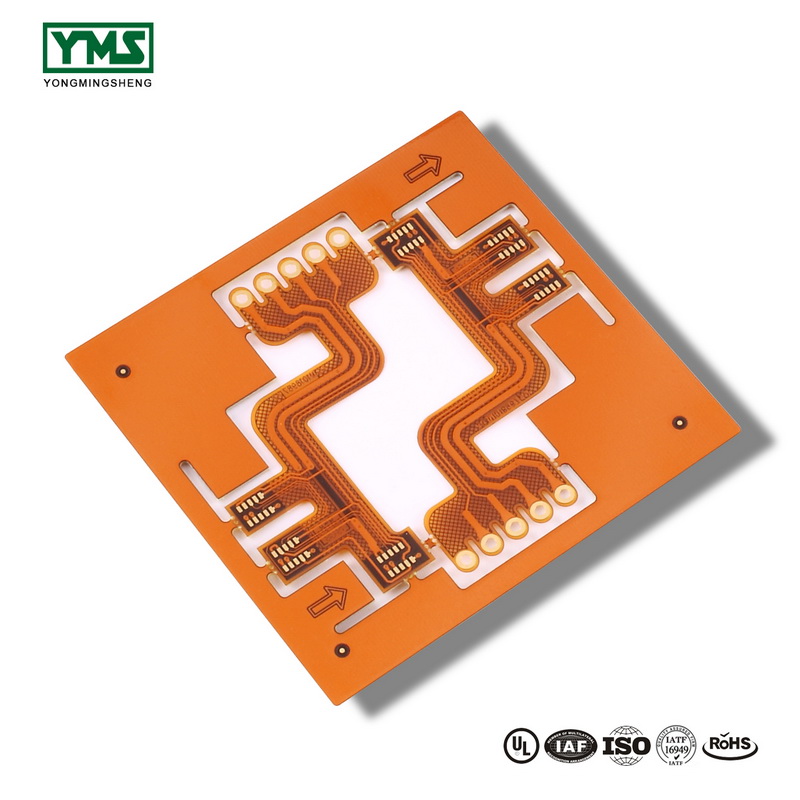

Images for fpc pcb

Post time: Aug-28-2019