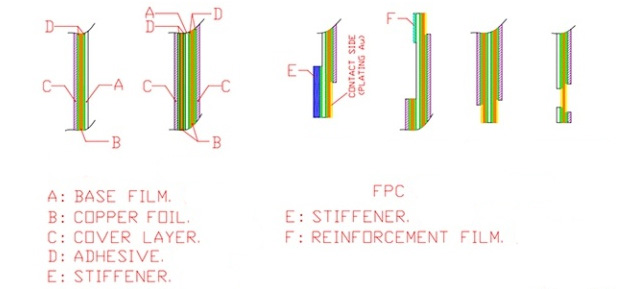

FPC soft printed circuit board, short for soft board, is made of soft plastic bottom film (PI), copper foil (CU) and adhesive, with excellent flexibility and reliability.

FPC pressure screeb flat cable surface treatment process:

Electrogilding: strong adhesion, good stability, good ductility.Plug – in FPC must be electroplated gold.

Chemical gold: poor adhesion, good uniformity, unable to bond, easy to crack.

FPC can be divided into single-layer board, double-layer board, layering board, multilayer layering board, Flex-Rigid board, etc. FPC above two layers are connected to each layer through the conduction hole.

Structural materials of FPC pressure screen flat cable:

1. Base: PI polyimide is commonly used as the material, and PET polyester is also used. Material thickness is 12.5, 25, 50, 75, 125um. 12.5 and 25um is usually used. PI is better than PET in all aspects of performance.

2. Copper foil layer: there are two calendering copper and electrolytic copper, the material thickness is 18, 35, 75um. And calendering copper has better mechanical properties than electrolytic copper, it is preferred to calendering copper in FPC screen-pressing line which needs to be bent frequently. Copper foil thickness of home screen FPC is generally 18um.

3. Covering layer: the same material as the base layer, covering on the copper foil, plays the role of insulation, welding resistance and protection.The material thickness is 12.5um.

4. Adhesive: adhesive to each layer.

5. Stiffener plate and reinforcing film: for plug-in FPC, in order to cooperate with standard socket, a stiffener plate should be added on the back of contact surface. PI, PET and FR4 can be used as materials. And usually PET will be used. The thickness of the contact position after fitting of the stiffener plate depends on the requirements of the socket, generally 0.3, 0.2 or 0.12mm. For the FPC terminal that needs bonding to LCD, it is required to design and strengthen the film on the back of the contact surface and adopt the PI material of 12.5um.

YMS is a PCB manufacturer in China, We offer competitive price with high quality flexible Board,PCB bare board,Rigid+Flex ;

Post time: Aug-23-2019