Conversion of copper thickness units

Copper thickness of PCB is all calculated by oz, 1oz means that the average weight of copper foil is 28.35g on an area of 1 square foot. Oz is the abbreviation of unit ounce, transliterated as "ounce", which is a British measure unit, also known as two ounces when used as a unit of weight.

It is expressed by weight per unit area as the average thickness of copper foil.1OZ=28.35g/ FT2.

Weight unit:

1oz=28.35g, 1oz=16 DRAM, 16 oz= 1 pound

Introduction to conversion method:

The weight of copper foil divided by the density and surface area of copper is the thickness of copper foil

1 square foot =929.0304 square centimeters, copper density =8.9kg/dm^3

Set Copper thickness as X to solve the equation:

X*929.0304 sq. cm *8.9 g/cm3 =1oz=28.35 g X=0.0034287 cm =34.287um

So 1 oz = 34.287 um

The thickness of 1OZ copper foil is about 35um or 1.35mil.

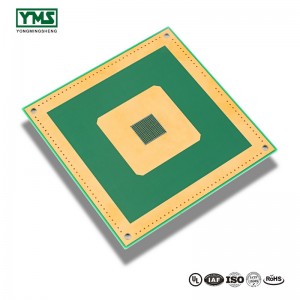

Product introduction of heavy copper board

Product types: single-layer, double-layer and multi-layer printed circuit board (PCB), flexible printed circuit board, buried hole and blind hole board.

Maximum processing size: single-layer board, double-layer board: 1000mm * 600mm, multi-layer board: 600mm * 600mm.

Top floor: 20 floor

Thickness of processed board: rigid board 0.4mm-4.0mm, flexible board 0.025mm-- 0.15mm.

Base material copper foil thickness: rigid board 18 (1/2oz),35 (1OZ),70 (2OZ) flexible board 0.009mm 0.018mm 0.035mm 0.070mm 0.010mm

Common substrates: fr-4, cem-3, cem-1, 94HB, 94VO, polytetrachloroethylene, polyester, polyacylammonium.

Process capacity:

(1) Drilling: minimum aperture 0.15mm

(2) Hole metallization: minimum aperture 0.15mm, board thickness/aperture ratio 4:1

(3) Wire width: minimum wire width: gold plate 0.075mm, tin board 0.10mm

(4) Wire spacing: minimum spacing: gold plate 0.075mm, tin board 0.10mm

(5) Gold plate: thickness of nickel layer: > or =2.5 micron thickness: 0.05-0.1 micron or as required by customers

(6) Tin spray board: tin layer thickness: > or =2.5-5 mu

(7) Milling board: minimum distance from line to edge: 0.15mm minimum distance from hole to edge: 0.2mm minimum contour tolerance: ± 0.12mm

(8) Socket chamfer: Angle: 30 °, 45 °, 60 ° depth: 1-3mm

(9) V cutting: Angle: 30 degrees, 35 degrees, 45 degrees depth: board thickness 2/3 minimum size: 80mm * 80mm

(10) On-off test:

Welding resistance: 85-- 105℃ / 280℃-- 360℃

Flexural resistance/chemical resistance of flexible board: fully accord with international standard

Introduction of heavy copper pcb technology

A、Preparation and plating treatment before plating

The main purpose of thickening copper plating is to ensure that there is enough thick copper coating in the hole to ensure that the resistance value is within the range required by the process. Fixed position and ensure connection strength as insert. As surface encapsulated devices, some holes are only used as conducting holes to conduct electricity on both sides.

(1) Inspection items

1. Mainly check the metallization quality of the hole, and ensure that there is no excess matter, burr, black hole, hole, etc.;

2. Check the surface of the substrate for dirt and other residues;

3. Check the number, drawing number, process documents and process instructions of the substrate;

4. Find out the mounting parts, mounting requirements and the plating area that the plating bath can bear;

5. The plating area and process parameters should be clear to ensure the stability and feasibility of the plating process parameters;

6. The solution is activated by cleaning and preparing the conductive part and electrifying the solution first;

7. Determine whether the liquid composition is qualified and the surface area of the board is in a state;If a spherical anode is installed in a column, the consumption must be checked;

8. Check the firmness of the contact parts and the range of voltage and current fluctuation.

(2) Quality control of thickening copper plating

1. Accurately calculate the plating area and the influence of the actual production process on the current, correctly determine the required value of the current, master the change of the current in the plating process, and ensure the stability of the plating process parameters;

2. Before electroplating, the commissioning board shall be first used for trial plating, resulting in the activation of the bath;

3. Determine the flow direction of the total current, and then determine the sequence order of the hanging baord. In principle, it should be used from far to near. Ensure the uniformity of current distribution on any surface.

4. Ensure the uniformity and consistency of coating thickness in the hole. In addition to the technological measures of stirring and filtration, shock current should also be adopted;

5. Constantly monitor the current changes in the electroplating process to ensure the reliability and stability of current values;

6. Test whether the copper plating layer thickness of the hole meets the technical requirements.

B、Copper plating process

In the process of thickening copper plating, it is necessary to monitor the process parameters frequently, which often causes unnecessary losses due to subjective and objective reasons. To do a good job in thickening copper plating process, it must be done in the following aspects:

1. According to the area value calculated by the computer and combined with the empirical constant accumulated in actual production, increase a certain number;

2. According to the calculated current value, in order to ensure the integrity of the coating in the hole, it is necessary to add a certain value to the original current value, that is, the impulse current, and then return to the original value within a short time;

3. When the electroplating of the circuit board reaches 5 minutes, take out the substrate to observe whether the copper layer on the surface and the inner wall of the hole is complete or not, and it is better to have metallic luster in all the holes;

4. A certain distance must be maintained between the substrate and the substrate;

5. When the thickened copper plating reaches the required plating time, a certain amount of current should be maintained during the removal of the substrate to ensure that the subsequent substrate surface and hole will not produce blackening or darkening.

Notes:

1. Check the process documents, read the process requirements and be familiar with the substrate machining blue chart;

2. Check the surface of the substrate for scratches, indentation, copper exposure and other phenomena;

3. According to the mechanical processing floppy disk for trial processing, the first piece of pre-inspection, meet the process requirements and then all the workpiece processing;

4. Prepare gauges and other tools used to monitor the geometric dimensions of the substrate;

5. According to the raw material properties of the processed substrate, select the appropriate milling tool (milling cutter).

C、Quality control

1. Strictly implement the first-piece inspection system to ensure that the product size meets the design requirements;

2. Reasonably select milling process parameters according to the raw materials of circuit boards;

3. When fixing the position of the circuit board, carefully install the clamp, so as to avoid damage to the solder layer and solder mask layer on the surface of the circuit board;

4. The position accuracy must be strictly controlled to ensure the consistency of the appearance size of the substrate;

5. In the process of disassembly, special attention should be paid to the substrate layer to pad paper, in order to avoid damage to the PCB surface coating layer.

You May Like:

Post time: Sep-11-2019