The development of circuit board has derived many kinds, but most of them can be divided into two kinds: PCB and flexible printed circuit board, and today we will talk about the structure of flexible printed circuit board.

General circuit board is divided into layers according to the number and thickness of conductive copper foil, they can be divided into single-layer board, double-layer board and multi-layer board, their structure is also different, here to introduce their different properties.

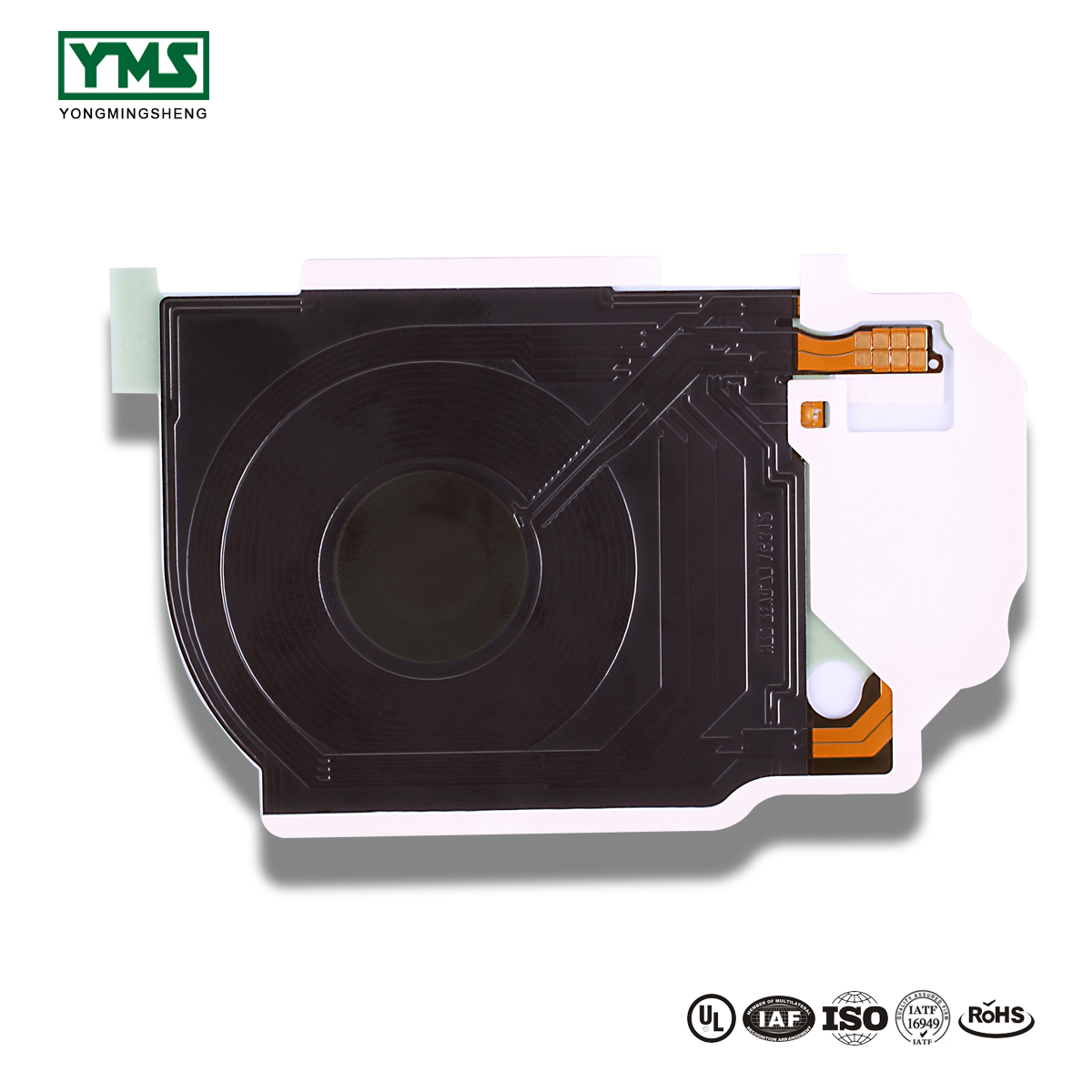

1Layer camera module Flexible Board

The structure of single-layer board: this is the most simple flexible board. Usually made of a set of raw materials like base material + protective film + transparent adhesive + copper foil. First of all, the copper foil for etching process to get need circuit, such as drilling to protective film to show the corresponding welding plate. After cleaning, the copper foil is combined with the protective film by rolling method. Then the exposed parts of the welding plate are electrically plated gold or tin for protection. In this way, the big board is ready, and it needs to be stamped into the corresponding shape of the small circuit board.

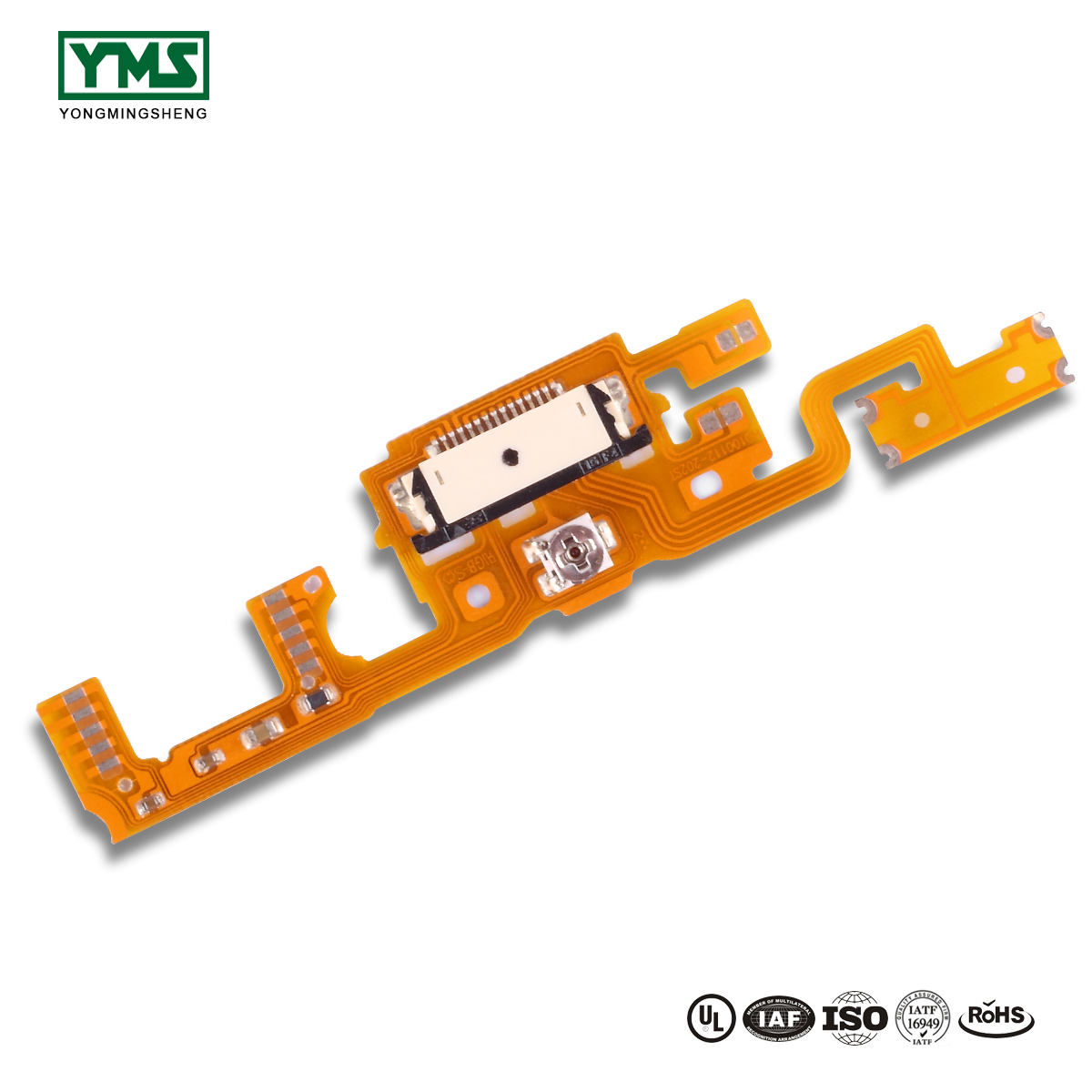

The structure of double-layer board: when the wiring is too complex, single-layer board cannot be wired or copper foil is needed for grounding shielding, double-layer board or multi-layer board is required. there are welding pads on both sides of the double-layer board, mainly used for connecting with other circuit boards. Although it is similar to the structure of single-layer board, its production process is very different. Its raw material is copper foil, protective film and transparent adhesive. First, drill holes on the protective film according to the position requirements of the welding pad, and then paste the copper foil.

The structure of multi-layer board: the most typical difference between multi-layer board and single-layer board is the addition of a through-hole structure to connect the layers of copper foil. Generally, the first processing process of substrate + transparent adhesive + copper foil is to make through-hole. First, drill holes in the substrate and copper foil, clean and then plated with a certain thickness of copper, so that through the hole is done, behind the production process is almost the same as single-layer board.

FPC has different types of structures, but many manufacturing processes have the same features, but different processes are added in some basic places to correspond to different fields.

Yongmingsheng is a China PCB manufacturer. Our products include:1OZ,2OZ,3OZ Copper FPC

Post time: Aug-20-2019