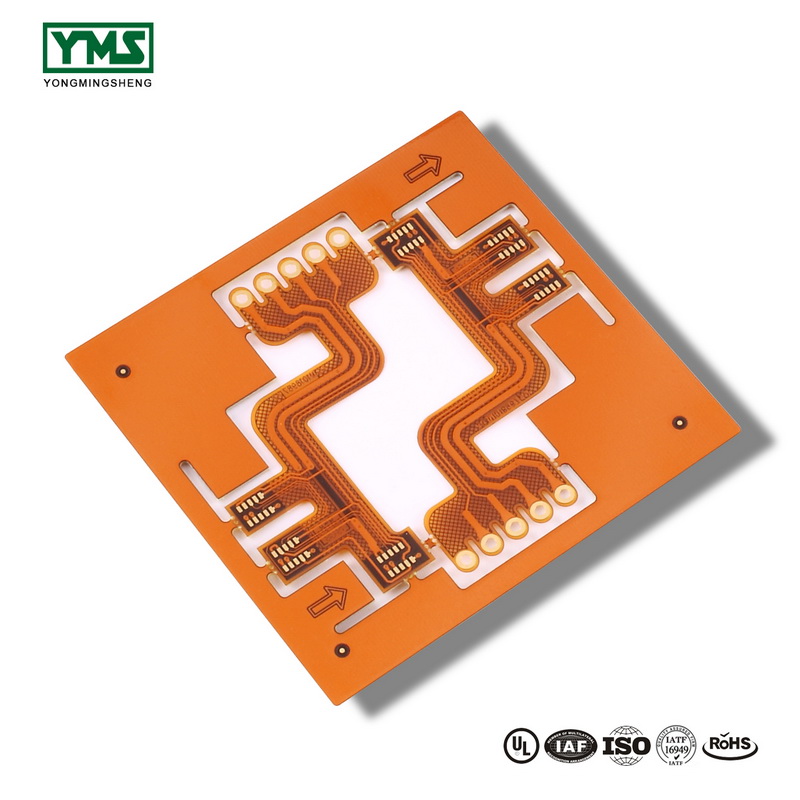

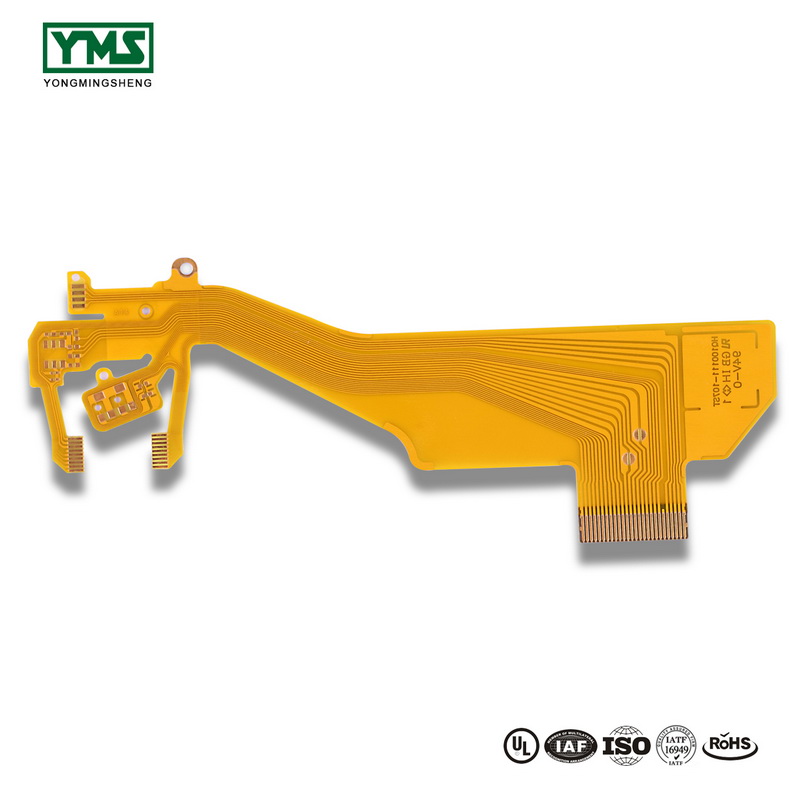

Description of FPC flexible circuit board storage period:

1. The exposed part of FPC conductor shall be treated with surface coating, such as gold plating, OSP, tin plating, etc. The storage environment shall be free from corrosive gases, and the temperature shall be controlled below 25℃, and the humidity shall be controlled at 50-70%.

2. Under the above storage conditions, the effective storage period of the products is 6 months after leaving the factory, with vacuum packaging of desiccant, and the storage period is 1 year.

3. Products after expiration of the warranty period will only affect welding, but have no impact on other aspects.

FPC flexible circuit board SMT operation requirements:

1. The substrate material used by FPC has hygroscopic properties. If the customer has high temperature in the process of manufacturing or needs to go through the SMT process, the baking shall be conducted to dehumidify before the operation, so as to avoid the occurrence of holes, bubbles, delamination and other defects in the product.

2. It is generally recommended to bake at 110-130℃ and for 60-120 minutes before SMT operation.

3. FPC shall conduct on-line operation within 2 hours after baking before operation. If more than 2 hours of waiting materials are not in operation, it shall conduct baking again to avoid the plate moisture absorption and affect SMT operation.

4. FPC has folding resistance, so the welding position of the back of the parts need to be stiffener design, to protect the welding spot and exposed line area from external influence, if there is no such stiffener design, avoid any bending action in the parts area, so as to avoid the occurrence of solder crack doubts.

FPC flexible circuit board bending instructions:

1. Although FPC emphasizes bendability, if 180° dead folding is carried out, there will still be bad breakage.

2. Most of the protection layer of ink type is not resistant to bending, so the protection ink printing area on the FPC surface, such as text, marking, anti-welding and other areas, is forbidden to bend more than 90° during assembly.

3. The junction between the covering film or stiffener board and the exposed area of conductor, such as the end of pulling and inserting the golden finger, is the area where the stress is concentrated. It is easy to produce the bad doubt of line fracture due to the stress concentration in the assembly process, which reminds FPC users to pay attention to this phenomenon.

4. The corner of FPC shape is the same area where the stress is concentrated. It is easy to tear in the assembly process.

5. FPC conductor exposed part, surface coating treatment, such as gold plating, the focus is to prevent oxidation, this area is not suitable for bending action.

6. Although there is a design of stiffener board, it is not suitable for bending in the general goldfinger insertion and withdrawal area. Special attention should be paid to the assembly of back-end components.

7. Do not bend directly on the lead hole of flexible circuit board to avoid reliability concerns.

Post time: Aug-26-2019