First let's introduce what is heavy gold?

The copper on the circuit board copper is mainly red copper, which is easily oxidized in the air. This will cause poor electrical conductivity that is solder bad or poor contact, reducing the performance of the circuit board, so need to surface treatment of copper solder. Immersion gold is gold is to coat it with gold, which can effectively prevent the oxidation ofcopper metal and air. Therefore, immersion gold is a way of dealing with surface anti-oxidation, is through the chemical reaction on the surface of copper covered with a layer of gold.

So what is gold finger?

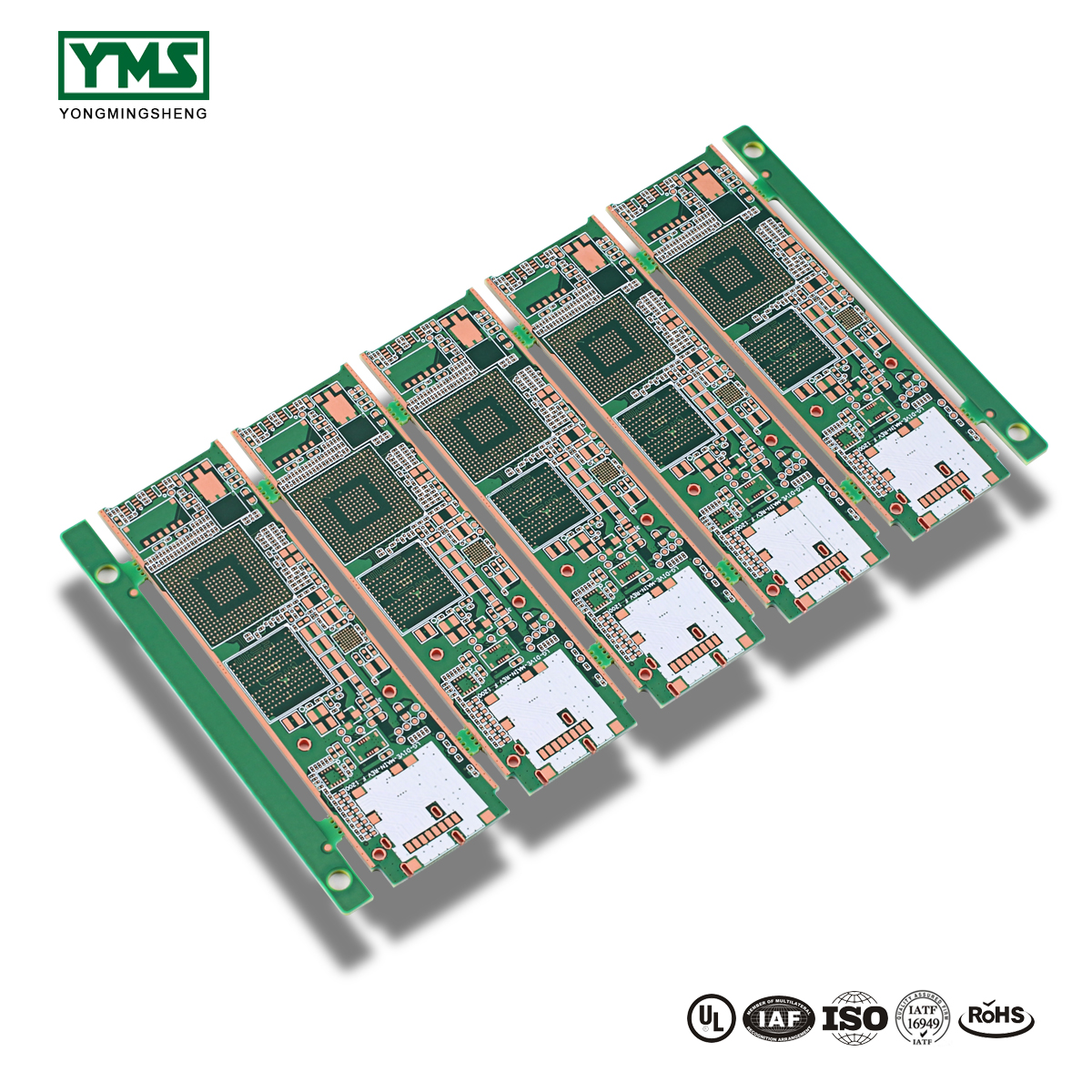

To put it bluntly, a brass contact is a conductor.Specifically, the components connected to the memory slots on the memory stick, all signals are transmitted through the gold finger, there are many yellow conductive contacts, its surface gold plated and conductive contacts arranged like fingers, hence the name.

The advantage of gold deposition process is that the color is very stable, the brightness is very good, the coating is very flat, the weldability is very good.

Generally, the gold precipitation thickness is 1-3 Uinch, which can be basically divided into four stages to complete: pre-treatment (oil removal, slight erosion, activation, leaching), nickel deposition, gold precipitation, post-treatment (waste gold washing, DI washing, drying).

However, compared with other tin spraying process on the production cost, the cost is relatively high, if the thickness of gold exceed the plate factory's conventional process, then the cost is even more expensive, of course, if you have high requirements for the plate weldability and electrical properties.

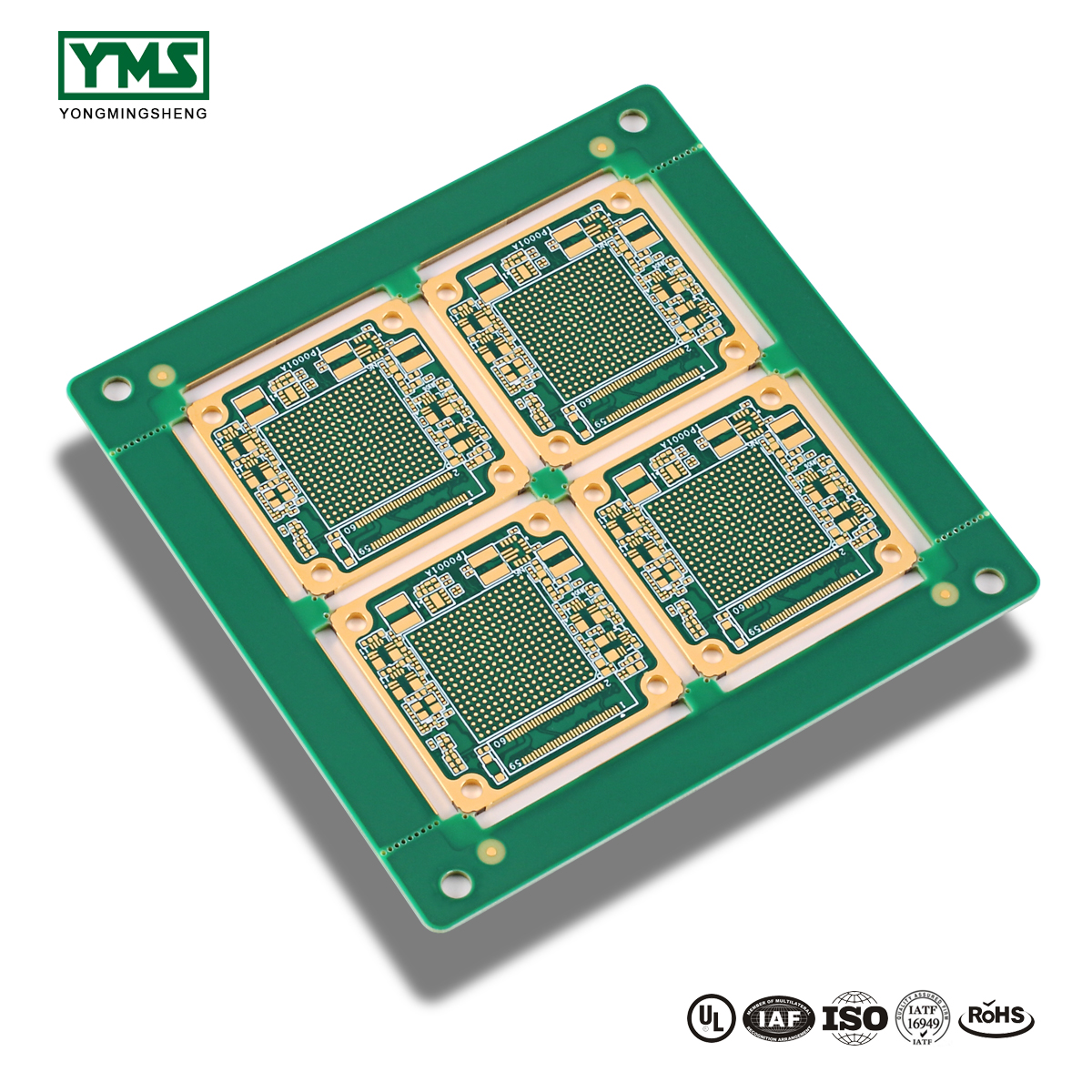

Such as: your circuit board with the fingers need to immersion gold, or the line width of the board/pad spacing is not enough, so it is best to do heavy + gold plating process for the finger, this circuit board welding is very good, circuit performance is also stable, bonding pad will not fall off, not bad contact, there will be no short circuit etc. At the same time also is very shock drop, of course, we won't fall off the board.

There is a kind of situation is the circuit board has gold finger, however, tin spraying process of the surface beyond the gold finger can be selected according to the situation. That is tin spraying + gold-plated finger process, in the circuit board line width and sufficient spacing between the pads, welding requirements are not high, can effectively reduce the production cost, and does not affect the use of the board.

However, if the line width of the board and the lack of space between the pads, then this situation using tin spraying technology will increase the difficulty of production, there will be tin bypass and other short circuit will be more, will give cash finger often inserted, resulting in poor contact.

So we can according to their actual situation of the circuit board, to choose their own plate technology, that is, control the cost and can not affect the use of the board.

Yongmingsheng is a China PCB manufacturer. Our products include: metal core PCB, aluminum base board; welcome to consult !

Post time: Aug-17-2019