Copper base board and aluminum base board difference

1. The thermal conductivity of copper base board is twice that of aluminum base board. The higher the thermal conductivity is, the higher the thermal conductivity is, and the better the heat dissipation function is.

2. Copper base board can be processed into metallized holes, while aluminum base board cannot.

3. The elastic modulus of copper and aluminum is quite different, so the warp and shrinkage of copper base board are smaller than that of aluminum base board.

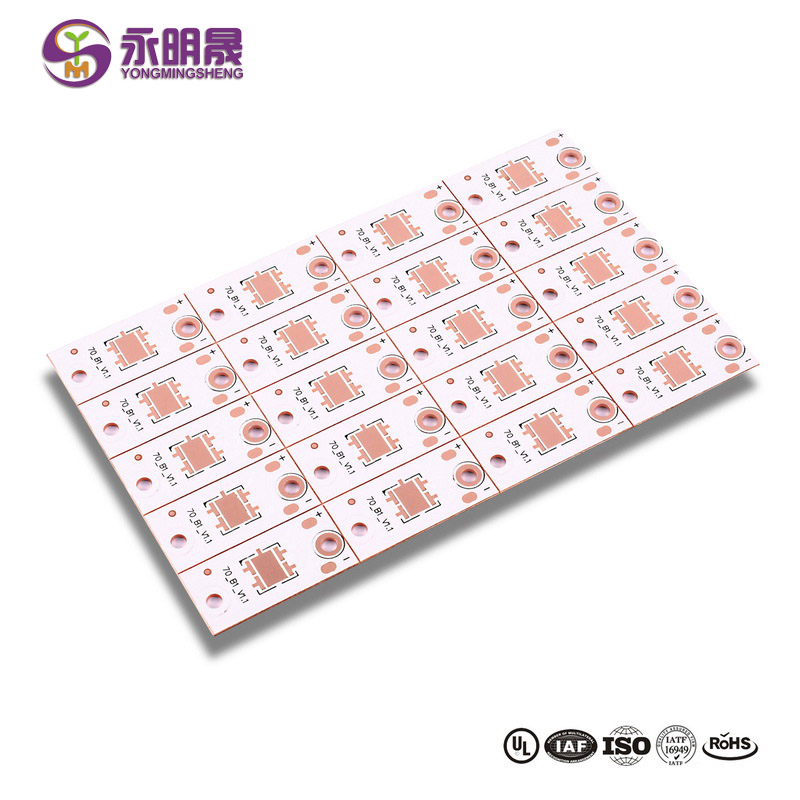

Copper base board

Copper base board is the most expensive metal base board, thermal conductivity than aluminum base board and iron base board are many times better;

It is suitable for high frequency circuit and high and low temperature change area and precision communication equipment heat dissipation and building decoration industry

Aluminum base board

Aluminum base board is a kind of copper clad metal base board with good heat dissipation function.

Generally, a single panel consists of three layers, namely, a circuit layer (copper foil), an insulating layer and a metal base layer.

For high-end use, there are also two panels, the structure of the circuit layer, insulation layer, aluminum base, insulation layer, circuit layer.

Very few applications for multi-layer board, can be made of ordinary multi-layer board ,insulation layer and aluminum base baord.

You May Like:

Post time: Sep-07-2019