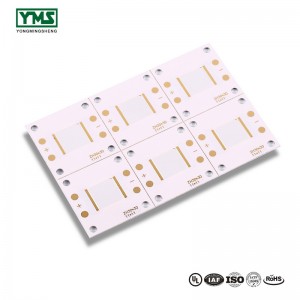

Overview of copper clad board

Copper clad board--- also known as base material. The stiffener material is soaked in resin, and one or both sides are covered with copper foil.

It is the basic material of PCB, often called base material. When it is used in multilayer production, it is also called CORE.

Classification of copper clad boards

A. According to the mechanical rigidity of copper-clad board, it is divided into rigid copper-clad board and flexible copper-clad board.

B. According to the insulation materials and structures of copper-clad boards, it can be divided into organic resin copper-clad boards, metal core PCB and ceramic-based copper-clad boards.

C. According to the thickness of copper-clad board, it is divided into thick board (the thickness range is 0.8 ~ 3.2mm (including Cu)) and thin board (the thickness range is less than 0.78mm (excluding Cu)).

D. According to the stiffener materials of copper clad boards, they are divided into glass cloth copper clad boards, paper copper clad boards and composite copper clad boards (cme-1 and cme-2).

E. Classified into flame retardant board and non-flame retardant board according to flame retardant grade.

F. According to some properties of copper clad board, it can be divided into high Tg board (Tg≥170℃), high dielectric property board, high CTI board (CTI≥600V), environment-friendly copper clad board (halogen-free, antimony-free), and ultraviolet shaded copper clad board.

The use of copper clad board

Copper clad board is the basic material of electronic industry, mainly used for processing and manufacturing printed circuit board (PCB), widely used in television, radio, computer, computer, mobile communication and other electronic products.

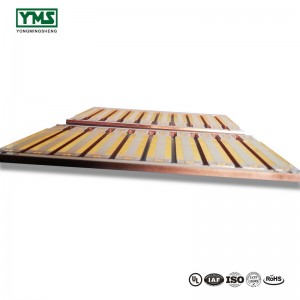

Working principle of aluminum base board

The surface of the power device is mounted on the circuit layer, and the heat generated during the operation of the device is rapidly transmitted to the metal base layer through the insulation layer, and then the metal base layer transfers the heat out, so as to realize the heat dissipation of the device.

Compared with the traditional fr-4, the aluminum base board can reduce the thermal resistance to the minimum, so that the aluminum base board has excellent thermal conductivity. Compared with the thick film ceramic circuit, its mechanical properties are excellent.

In addition, aluminum base board has the following unique advantages:

Meet RoHs requirements.

More suitable for SMT process.

In the circuit design scheme, heat diffusion is treated effectively to reduce the module operating temperature, prolong the service life, and improve the power density and reliability.

Reduce the assembly of radiators and other hardware (including thermal interface materials), reduce the volume of products, and reduce the cost of hardware and assembly, optimize power circuit and control circuit.

Replace fragile ceramic substrate for better mechanical endurance.

Aluminum base board composition

Circuit layer

The circuit layer (usually electrolytic copper foil) is etched to form a printed circuit, which is used to realize the assembly and connection of devices. Compared with the traditional fr-4, the aluminum base board can carry higher current with the same thickness and line width.

Insulating layer

Insulation layer is the core technology of aluminum base board, which mainly plays the functions of bonding, insulation and heat conduction. Aluminum base board insulation layer is the largest thermal conductivity barrier in power module structure. The better the heat conduction performance of the insulation layer is, the more conducive it is to the diffusion of heat generated during the operation of the device, and the more conducive it is to reducing the operating temperature of the device, so as to increase the power load of the module, reduce the volume, prolong the life and increase the power output.

The metal base

The type of metal used for insulating metal base board depends on the thermal expansion coefficient, thermal conductivity, strength, hardness, weight, surface condition and cost of the metal base board.

In general, from the cost and technical performance and other conditions to consider, aluminum base board is the ideal choice. The available aluminum plates are 6061,5052,1060, etc. Copper board, stainless steel board, iron board and silicon steel board can also be used if higher thermal conductivity, mechanical properties, electrical properties and other special properties are required.

Copper clad board and aluminum base board four major differences

1. Heat dissipation

Heat dissipation of aluminum base board is higher than that of copper composite board, heat dissipation of aluminum base board and its insulation layer density and thermal conductivity, the thinner the insulation layer, the higher the thermal conductivity coefficient.

2. Mechanical functions

Compared with copper clad board, aluminum base board is better than copper clad board. Aluminum base board has high mechanical strength and tolerance, so it can be printed on aluminum base board.

3. Electromagnetic shielding function

Aluminum base board can be used as shielding board to shield electromagnetic wave effect, but better than copper clad board.

4. Coefficient of thermal expansion

Because of the general thermal expansion of copper cladding, it is easy to affect the quality of metal holes and wires. The thermal expansion coefficient of aluminum base board is lower than that of copper composite plate, which helps to ensure the quality and reliability of printed circuit board.

You May Like:

Post time: Sep-09-2019