The heat dissipation of led is the biggest headache for led manufacturers. However, aluminum base board can be used, because aluminum has high thermal conductivity and good heat dissipation, which can effectively export the internal heat.

Aluminum PCB is a unique metal substrate copper clad plate, with good thermal conductivity, electrical insulation and mechanical properties. The PCB should be placed as close as possible to the aluminum base to reduce the thermal resistance of the potting adhesive.

First, the characteristics of aluminum substrate

1. Surface mount technology (SMT);

2. Extremely effective treatment of heat diffusion in circuit design scheme;

3. Reduce product operating temperature, improve product power density and reliability, and extend product service life;

4. Reduce the volume of products, reduce the cost of hardware and assembly;

5. Replace fragile ceramic substrate for better mechanical endurance.

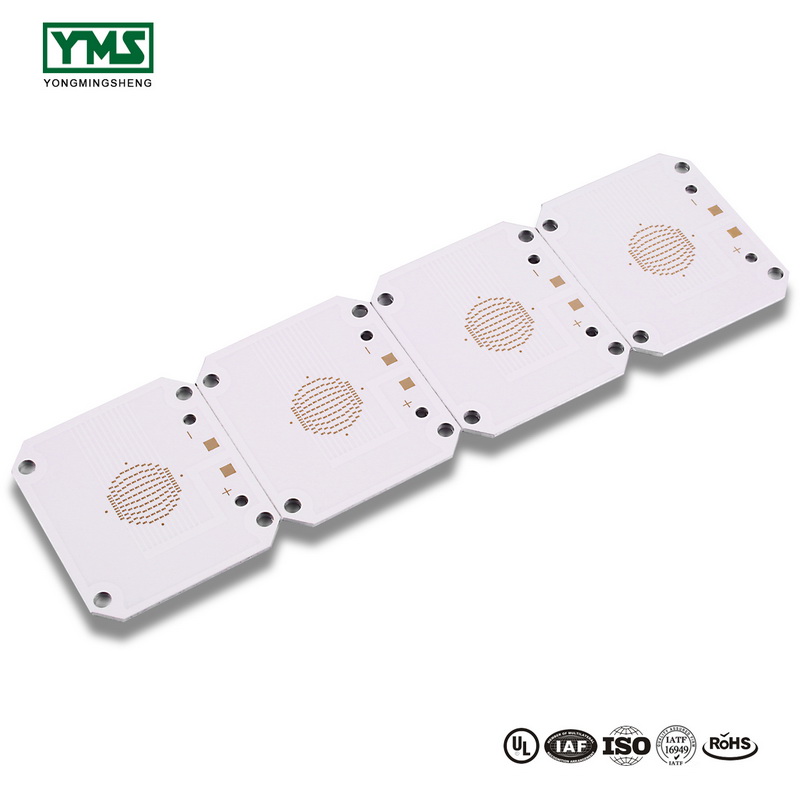

Structure of aluminum substrate

Aluminum clad copper plate is a kind of metal circuit board material, composed of copper foil, thermal insulation layer and metal substrate, its structure is divided into three layers:

Cireuitl Layer: equivalent to common PCB copper clad plate, thickness of copper foil 1oz to 10oz.

Insulation Layer: insulation layer is a layer of thermal conductivity insulation material with low thermal resistance.

BaseLayer base: it is a metal substrate, usually aluminum or optionally copper. Aluminum based copper clad board and traditional epoxy glass cloth laminate, etc.

The circuit layer (copper foil) is usually etched to form a printed circuit, so that the components are connected to each other. In general, the circuit layer is required to have a large current carrying capacity, so thicker copper foil should be used, the thickness of which is generally 35ms ~ 280ms.

Thermal insulation layer is the core technology of aluminum substrate, which is generally composed of special polymers filled with special ceramics, with small thermal resistance, good viscoelasticity, heat aging resistance, and can withstand mechanical and thermal stress.

It is precisely by using this technology that the thermal insulation layer of high performance aluminum base board has extremely excellent thermal conductivity and high strength electrical insulation performance.

The metal base is the support member of aluminum base board, which requires high thermal conductivity. Generally, it is aluminum board, but copper board can also be used (copper board can provide better thermal conductivity), which is suitable for drilling, punching, cutting and other conventional mechanical processing.

PCB material has incomparable advantages compared with other materials. Suitable for SMT surface mount of power element. Without radiator, the volume is greatly reduced, heat dissipation effect is excellent, good insulation and mechanical performance.

Searches related to aluminum pcb

Post time: Aug-29-2019