Newly Arrival94vo Printed Circuit Board - Rapid Delivery for Ems Printed Fr-4 Circuit Board Pcb – Yongmingsheng

Newly Arrival94vo Printed Circuit Board - Rapid Delivery for Ems Printed Fr-4 Circuit Board Pcb – Yongmingsheng Detail:

With this motto in mind, we have become one of the most technologically innovative, cost-efficient, and price-competitive manufacturers for Rapid Delivery for Ems Printed Fr-4 Circuit Board Pcb, In case you are interested in almost any of our objects, make sure you never wait to call us and go ahead and take initial step to construct up a successful business romance.

With this motto in mind, we have become one of the most technologically innovative, cost-efficient, and price-competitive manufacturers for Circuit Board Pcb, Pcb, Pcb Fr-4, If you need to have any of our merchandise, or have other items to be produced, make sure you send us your inquiries, samples or in depth drawings. Meanwhile, aiming to develop into an international enterprise group, we look forward to receiving offers for joint ventures and other cooperative projects.

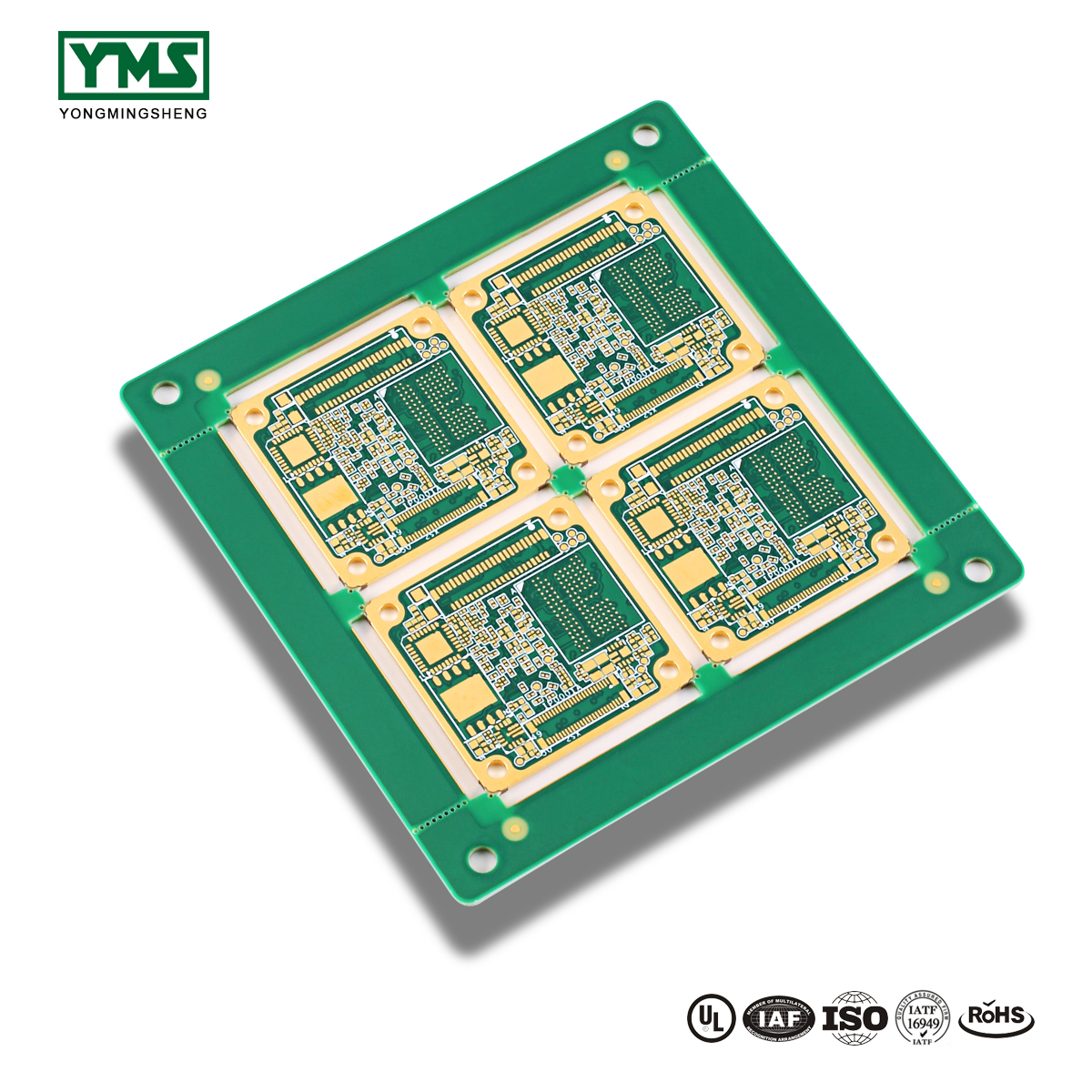

HDI Board production process:

At present, HDI board interconnection between layer and layer is mainly the following design: Staggered holes interconnection, Cross-layer interconnection, ladder interconnection and superposition holes interconnection. Among them, the superposition holes interconnection occupy the least space. There is a research suggests that reducing the number of through holes and increasing the number of blind holes can effectively improve the wiring density. And in the superposition interconnection, the methods of electroplating and resin plug are mainly used, especially the electroplating hole filling method which has more obvious advantages like high reliability and good conduction performance. Therefore, superposition interconnection is the most widely used design method for blind holes design. The process of stacking between layers is as follows: first blind hole is made, then second blind hole is made after lamination, then multi-blind hole is made according to this method, and the interconnection between layers is realized by electroplating hole filling method.

On the whole, the production process of HDI plate is complex, which needs to be completed after many times of production for a long time. It’s not only high requirements for the accuracy and shrinkage control of each layer, but also high standards in materials, equipment, environment and technical personnel.

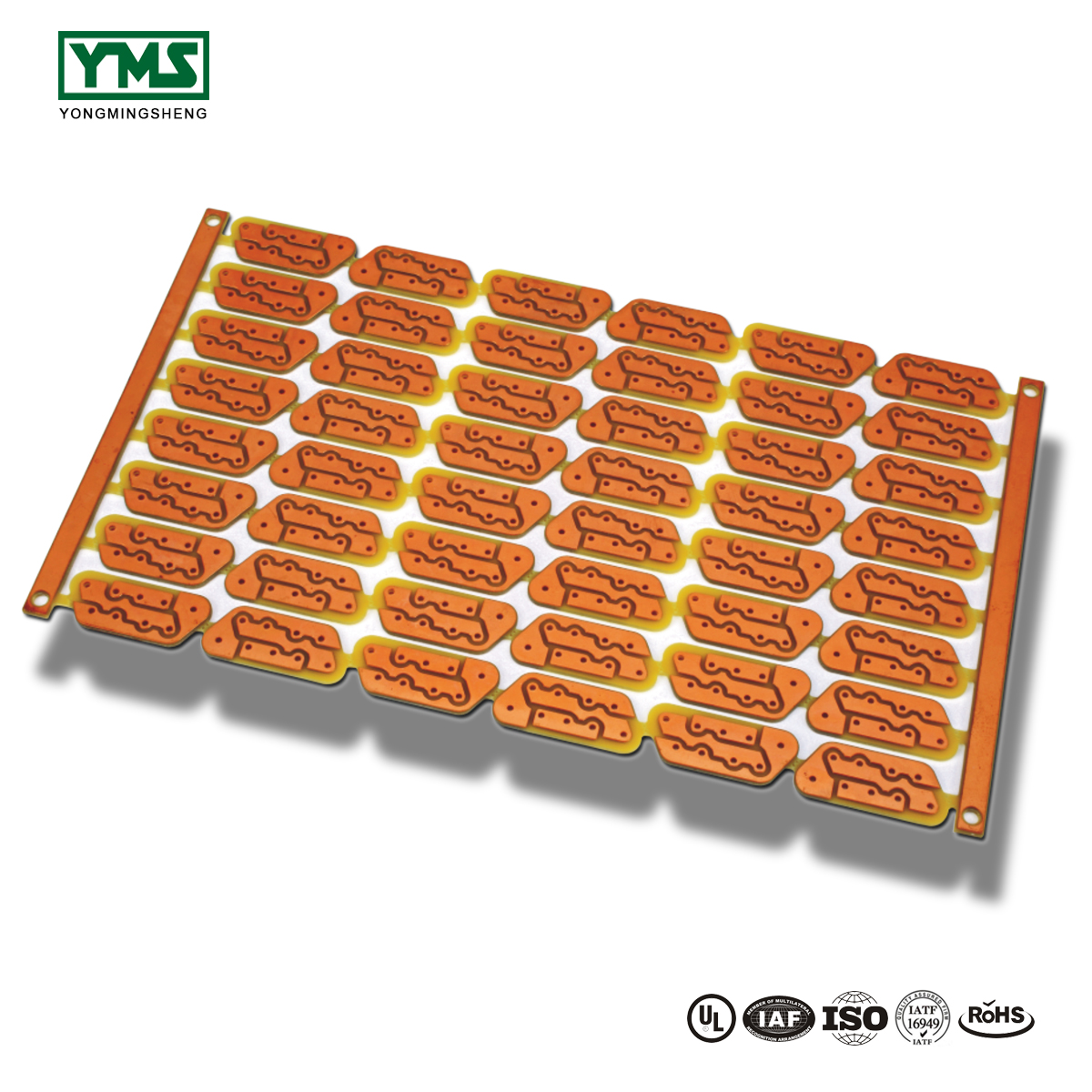

Product detail pictures:

Related Product Guide:

Hdi Microvia Pcb Market 2019 Types, Applications, Production, Consumption, Sales, Imports/Exports, Size & Share Forecast to 2024 | Rigid-Flexible Pcb

A ‘painless’ approach to energy: Upper Nappan home provides proof that living off-grid can be comfortable | Regional | News | Hdi Pcb

All we do is usually connected with our tenet " Customer to start with, Rely on initial, devoting on the food packaging and environmental protection for Newly Arrival94vo Printed Circuit Board - Rapid Delivery for Ems Printed Fr-4 Circuit Board Pcb – Yongmingsheng , The product will supply to all over the world, such as: Angola, Croatia, Italy, Our company abides by the management idea of "keep innovation, pursue excellence". On the basis of assuring the advantages of existing merchandise, we continuously strengthen and extend product development. Our company insists on innovation to promote the sustainable development of enterprise, and make us become the domestic high-quality suppliers.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.