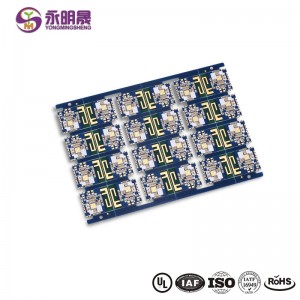

FR4 Multilayer PCB-Chian Wholesale Supplier | YMSPCB

FR-4 is a widely relevant material, popular mostly for its low cost and relative mechanical and electrical stability.

FR4 pcb definition

FR-4 (or FR4) is a grade designation assigned to glass-reinforced epoxy laminate sheets, tubes, rods and printed circuit boards (PCB). FR-4 is a composite material composed of woven fiberglass cloth with an epoxy resin binder that is flame resistant (self-extinguishing). FR4 is used in many multilayer boards.

"FR" stands for flame retardant, and denotes that safety of flammability of FR-4 is in compliance with the standard UL94V-0. FR-4 was created from the constituent materials (epoxy resin, woven glass fabric reinforcement, brominated flame retardant, etc.) by NEMA in 1968.

FR-4 glass epoxy is a popular and versatile high-pressure thermoset plastic laminate grade with good strength to weight ratios. With near zero water absorption, FR-4 is most commonly used as an electrical insulator possessing considerable mechanical strength. The material is known to retain its high mechanical values and electrical insulating qualities in both dry and humid conditions. These attributes, along with good fabrication characteristics, lend utility to this grade for a wide variety of electrical and mechanical applications.

NEMA is the regulating authority for FR-4 and other insulating laminate grades. Grade designations for glass epoxy laminates are: G10, G11, FR4, FR5 and FR6. Of these, FR4 is the grade most widely in use today. G-10, the predecessor to FR-4, lacks FR-4's self-extinguishing flammability characteristics. Hence, FR-4 has since[when?] replaced G-10 in most applications.

FR-4 epoxy resin systems typically employ bromine, a halogen, to facilitate flame-resistant properties in FR-4 glass epoxy laminates. Some applications where thermal destruction of the material is a desirable trait will still use G-10 non flame resistant.

Multilayer FR4 PCB Highlights

| Product Description | This Multi-Layer PCB is used within an Aerospace application | ||

| Capabilities Applied/Processes | Pull proper materials for Innerlayer manufacture | Conductive Polymer | Packaging |

| Cut Material To Size | Photolithography | Vacuum Packed | |

| Inner layer Fabrication (Image, Etch, and Oxide) | Plating (copper, solder) | ||

| Multilayer Lamination | Etching | ||

| CNC Primary Drilling | Hot Air Solder Leveling | ||

| Deburring | LPI Soldermask / Silk Screening | ||

| Plasma Smear Removal | Final Fabrication | ||

| Direct Metallizationul | |||

| Equipment Used | Alternative Oxide Line,CNC Driller,CNC Router,

EtcherFlying Probe Electrical Test,Hot Air Solder Leveler, Plasma Etch,UV Exposure Unit, Developer,Vacuum Lamination Press |

||

| Overall Part Dimensions | Layers: 12Length: 6"

Width: 11" |

Tightest Tolerances +/- .003" Plated Holes+/- 10% on etched features

±.005" Overall Routing Tolerances |

|

| Material Used | Multifunctional FR-4 (IPC 4101 / 26)High Temperature: 180C | ||

| Estimated Part Weight | 8 oz | ||

| In process testing performed | Cross Section AnalysisFull Electrical Testing

Solderability Testing |

||

| Standards Met | IPC-6012B - Qualification and Performance Specification for Rigid Printed Boards

IPC-A-600 - Acceptability of Printed Boards UL94V-0 |

FR4 pcb technology:

| Item | Parameter |

| Layer: | 1 to 24 layers |

| Material type: | FR-4, CEM-1, CEM-3, High TG, FR4 Halogen Free, Rogers |

| Board thickness: | 0.20mm to 3.4mm |

| Copper thickness: | 0.5 OZ to 6 OZ |

| Copper thickness in hole: | >25.0 um (>1mil) |

| Max. Board Size: | (580mm×1200mm) |

| Min. Drilled Hole Size: | 4mil(0.1mm) |

| Min. Line Width: | 3mil (0.075mm) |

| Min. Line Spacing: | 3mil (0.075mm) |

| Surface finishing: | HASL / HASL lead free, HAL, Chemical tin, Chemical Gold, Immersion Silver/Gold, OSP, Gold plating |

| Solder Mask Color: | Green/Yellow/Black/White/Red/Blue |

| Shape tolerance: | ±0.13 |

| Hole tolerance: | PTH: ±0.076 NPTH: ±0.05 |

| Package: | Inner packing: Vacuum packing / Plastic bag,Outer packing: Standard carton packing |

| Certificate: | UL,SGS,ISO 9001:2008 |

| Special requirements: | Buried and blind vias+controlled impedance +BGA |

| Profiling: | Punching, Routing, V-CUT, Beveling |

Standard FR-4 Material Properties

》High Glass Transition Temperature (Tg) (150Tg or 170Tg)

》High Decomposition Temperature (Td) (> 325º C)

》Low Coefficient of Thermal Expansion (CTE) ((3.0%-3.8%)

》Dielectric Constant (@1 GHz): 4.25-4.55

》Dissipation Factor (@ 1 GHz): 0.016

》UL rated (94V-0, CTI = 4)

》Compatible with standard and lead-free assembly.

》Laminate thickness available from 0.005” to 0.125”

Pre-preg thicknesses available (approximate after lamination):

150 Tg FR-4 material is used on all standard PCBExpress Quickturn, ValueProto and all PCBpro Full Feature orders unless another specific material or Tg is called out (PCBpro Full Feature or Custom Quote).

Application:

FR-4 is the primary insulating backbone upon which the vast majority of rigid printed circuit boards (PCBs) are produced. A thin layer of copper foil is laminated to one or both sides of an FR-4 glass epoxy panel. These are commonly referred to as per"copperclad laminates."

FR-4 copper-clad sheets are fabricated with circuitry interconnections etched into copper layers to produce printed circuit boards. More sophisticated and complex FR-4 printed circuit boards are produced in multiple layers, also known as "multilayer circuitry".

Specifications

When ordering a copper clad laminate board, the FR-4 thickness and the copper foil thickness must be specified separately.

In the USA, FR-4 thickness is specified in thou or inches, and common thicknesses range from 10 thou (0.010 in, 254 µm) to 3 inches (76 mm).

Copper foil thickness is specified in units of ounces per square foot (oz/ft2), commonly referred to simply as ounce. Common thicknesses are 1 oz/ft2(300 g/m2), 2 oz/ft2 (600 g/m2), and 3 oz/ft2 (900 g/m2). These work out to thicknesses of 34.1 µm (1.34 thou), 68.2 µm (2.68 thou), and 102.3 µm (4.02 thou), respectively. Some PCB manufacturers refer to 1 oz/ft2 copper foil as having a thickness of 35 µm (may also be referred to as 35 μ, 35 micron, or 35 mic).

Other applications

FR-4 is also used in the construction of relays, switches, standoffs, busbars, washers, arc shields, transformers and screw terminal strips.

Learn more about YMS products

Board1-300x300.jpg)